3.3

Section 3

Troubleshooting

3

NOTE: It is good practice to drain oil at a location

away from the workbench. Be sure to

allow ample time for complete drainage.

Cleaning the Engine

After inspecting the external condition of the engine,

clean the engine thoroughly before disassembling it.

Also clean individual components as the engine is

disassembled. Only clean parts can be accurately

inspected and gauged for wear or damage. There are

many commercially available cleaners that will quickly

remove grease, oil, and grime from engine parts. When

such a cleaner is used, follow the manufacturer’s

instructions and safety precautions carefully.

Make sure all traces of the cleaner are removed before

the engine is reassembled and placed into operation.

Even small amounts of these cleaners can quickly

break down the lubricating properties of engine oil.

Basic Engine Tests

Crankcase Vacuum Test

A partial vacuum should be present in the crankcase

when the engine is operating. Pressure in the

crankcase (normally caused by a clogged or improperly

assembled breather) can cause oil to be forced out at

oil seals, gaskets, or other available spots.

Crankcase vacuum is best measured with either

a water manometer (Kohler Part No. 25 761 02-S)

or a vacuum gauge (Kohler Part No. 25 761 22-S).

Complete instructions are provided in kits.

Test the crankcase vacuum with the manometer as

follows:

1. Insert the stopper/hose into the oil fill hole. Leave

the other tube of manometer open to atmosphere.

Make sure the shut-off clamp is closed.

2. Start the engine and run at no-load high idle

speed (3200 to 3750 RPM).

3. Open the clamp and note the water level in the

tube.

The level in the engine side should be a minimum

of 10.2 cm (4 in.) above the level in the open

side.

If the level in the engine side is less than

specified (low/no vacuum), or the level in the

engine side is lower than the level in the open

side (pressure), check for the conditions in the

table below.

4. Close the shut-off clamp before stopping the

engine.

Compression Test

A compression test is best performed on a warm

engine. Clean any dirt or debris away from the base

of the spark plugs before removing them. Be sure the

choke is off, and the throttle is wide open during the

test. Compression should be at least 160 psi and

should not vary more than 15% between cylinders.

Cylinder Leakdown Test

A cylinder leakdown test can be a valuable alternative

to a compression test. By pressurizing the combustion

chamber from an external air source you can

determine if the valves or rings are leaking, and how

badly.

Kohler Part No. 25 761 05-S is a relatively simple,

inexpensive leakdown tester for small engines. The

tester includes a quick disconnect for attaching the

adapter hose and a holding tool.

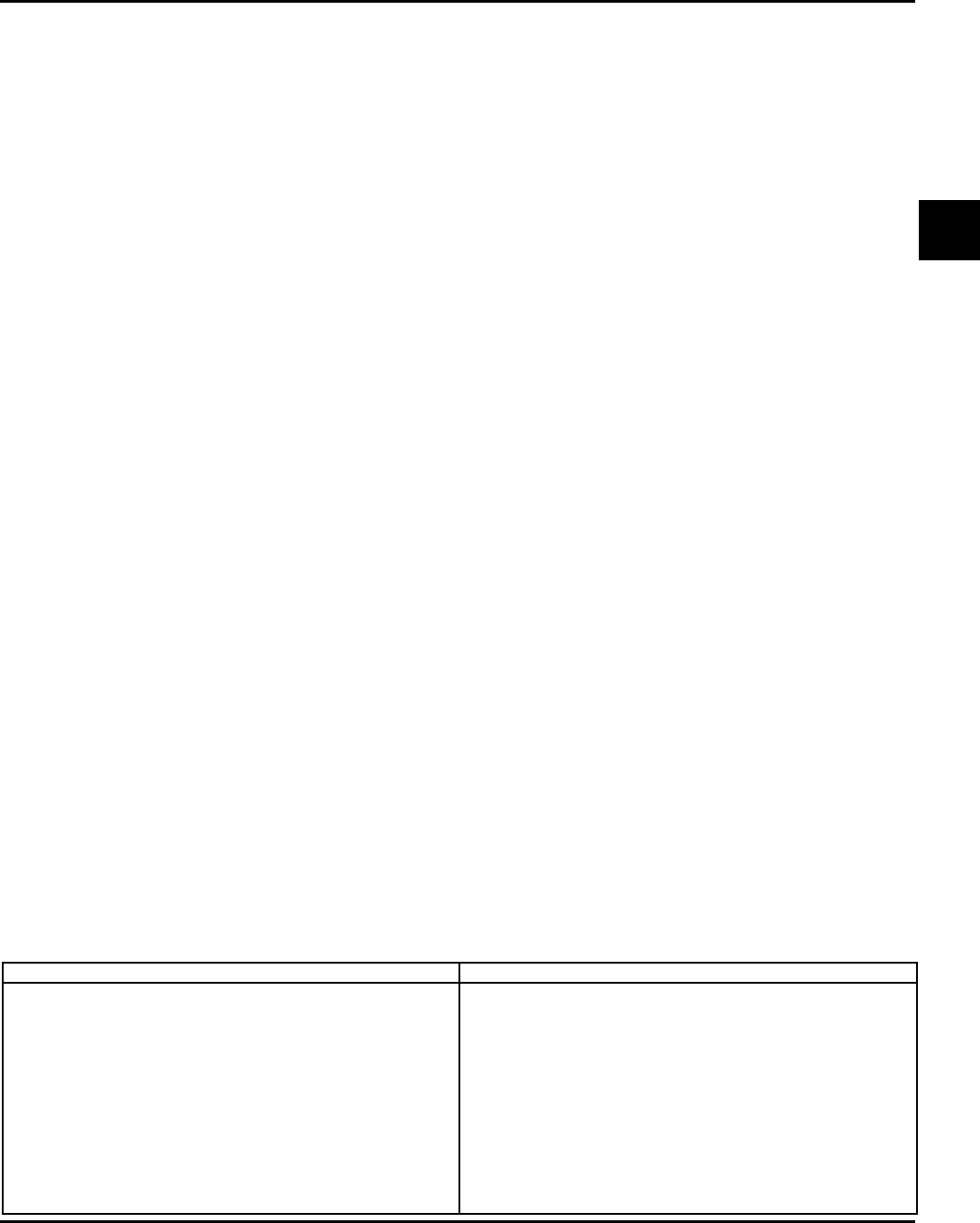

Possible Cause Solution

1. Replace breather assembly (valve cover).

2. Replace all worn or damaged seals and gaskets.

Make sure all fasteners are tightened securely.

Use appropriate torque values and sequences

when necessary.

3. Recondition piston, rings, cylinder bore, valves,

and valve guides.

4. Repair/replace restricted muffler/exhaust system.

1. Crankcase breather clogged or inoperative.

2. Seals and/or gaskets leaking. Loose or

improperly torqued fasteners.

3. Piston blowby or leaky valves. (Confirm by

inspecting components.)

4. Restricted exhaust.

No Crankcase Vacuum/Pressure in Crankcase