5.7

Section 5

Fuel System and Governor

5

Fuel Shut-off Solenoid

Carburetors are equipped with a fuel shut-off solenoid,

which also contains the main jet. The solenoid has a

spring loaded pin which retracts when the key switch is

‘‘on’’, allowing the engine to function normally. When

the key switch is turned ‘‘off’’, the pin extends and

prevents fuel from entering the engine.

Below is a simple test made with the engine off, that

can determine if the solenoid is functioning properly:

1. Shut off the fuel and remove the solenoid from the

carburetor. When the solenoid is loosened and

removed, gas will leak out of the carburetor. Have

a container ready to catch the fuel.

2. Wipe the tip of the solenoid with a shop towel or

blow it off with compressed air, to remove any

remaining fuel. Take the solenoid to a location

with good ventilation and no fuel vapors present.

You will need a 12 volt power source that can be

switched on and off.

3. Be sure the power source is switched off.

Connect the negative power source lead to the

black solenoid lead, and connect the positive

power source lead to the red lead of the solenoid.

Turn on the power source, while observing the pin

in the center of the solenoid.

4. If the pin retracted when the power source was

turned on, the solenoid is good. If the power

source is turned off, the pin should return to its

original position.

Adjustments

General

In compliance with government emission standards,

the carburetor is calibrated to deliver the correct air-to-

fuel mixture to the engine under all operating

conditions. Both the low and the high speed mixture

circuits are pre-established and cannot be adjusted.

The low idle speed (RPM) is the only adjustment

available.

NOTE: Low idle speed (RPM) adjustment should be

made only after the engine has warmed up.

Adjusting Low Idle Speed (RPM) Setting

1. Start the engine and run at half throttle for 5 to 10

minutes to warm up. The engine must be warm

before making final low idle speed (RPM)

adjustment. Check that the throttle and choke

plates can fully open.

2. Place the throttle control into the ‘‘idle’’ or ‘‘slow’’

position.

3. Set the low idle speed to 1200 RPM* (±75 RPM)

by turning the low idle speed adjusting screw in

or out. Check the speed using a tachometer.

*NOTE: The actual low idle speed depends on

the application. Refer to the equipment

manufacturer’s recommendations. The

low idle speed for basic engines is 1200

RPM. To ensure best results when

setting the low idle fuel needle, the low

idle speed should be 1200 RPM

(± 75 RPM).

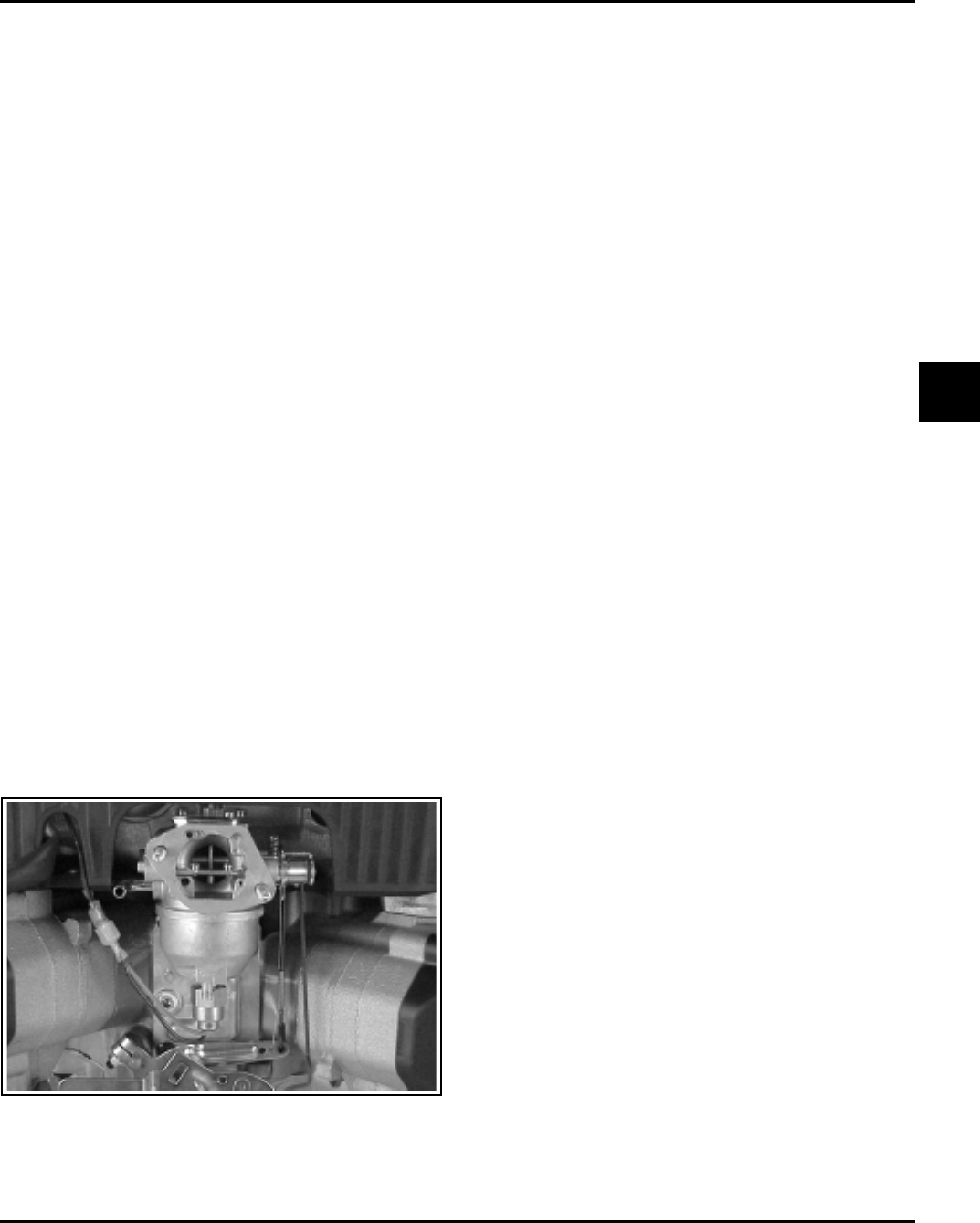

Figure 5-4. Carburetor and Solenoid.