11.7

Section 11

Reassembly

11

Figure 11-17. Applying Loctite to New Stud.

2. Tighten two nuts together on the shorter threaded

section.

3. Thread the end of the stud with the Loctite

®

into

the crankcase, until an exposed stud height of

75 mm (2.952 in.) is obtained. The end with the

dash mark must be out. See Figure 11-18. When

threading in the studs, use a steady tightening

motion without interruption until the proper

height is obtained. The frictional heat from the

engaging threads, may otherwise cause the

locking compound to set up prematurely.

Remove the two nuts.

Apply

Loctite

®

No. 272

Figure 11-18. Side View of Crankcase and Studs

for Height Dimension/Reference.

4. Repeat Steps 1-3 for each of the studs.

Install Hydraulic Lifters

1. Bleed the hydraulic lifters of internal oil so the

plunger in the lifter can be depressed by hand.

Use an old cutoff push rod mounted in a drill

press, arbor press, or vice, and slowly apply

pressure two or three times to bleed the lifters.

See Figure 11-19. If a vice is used in bleeding

the lifters, be sure to install protective coverings

over the jaws to avoid damage to the base of

the lifter(s).

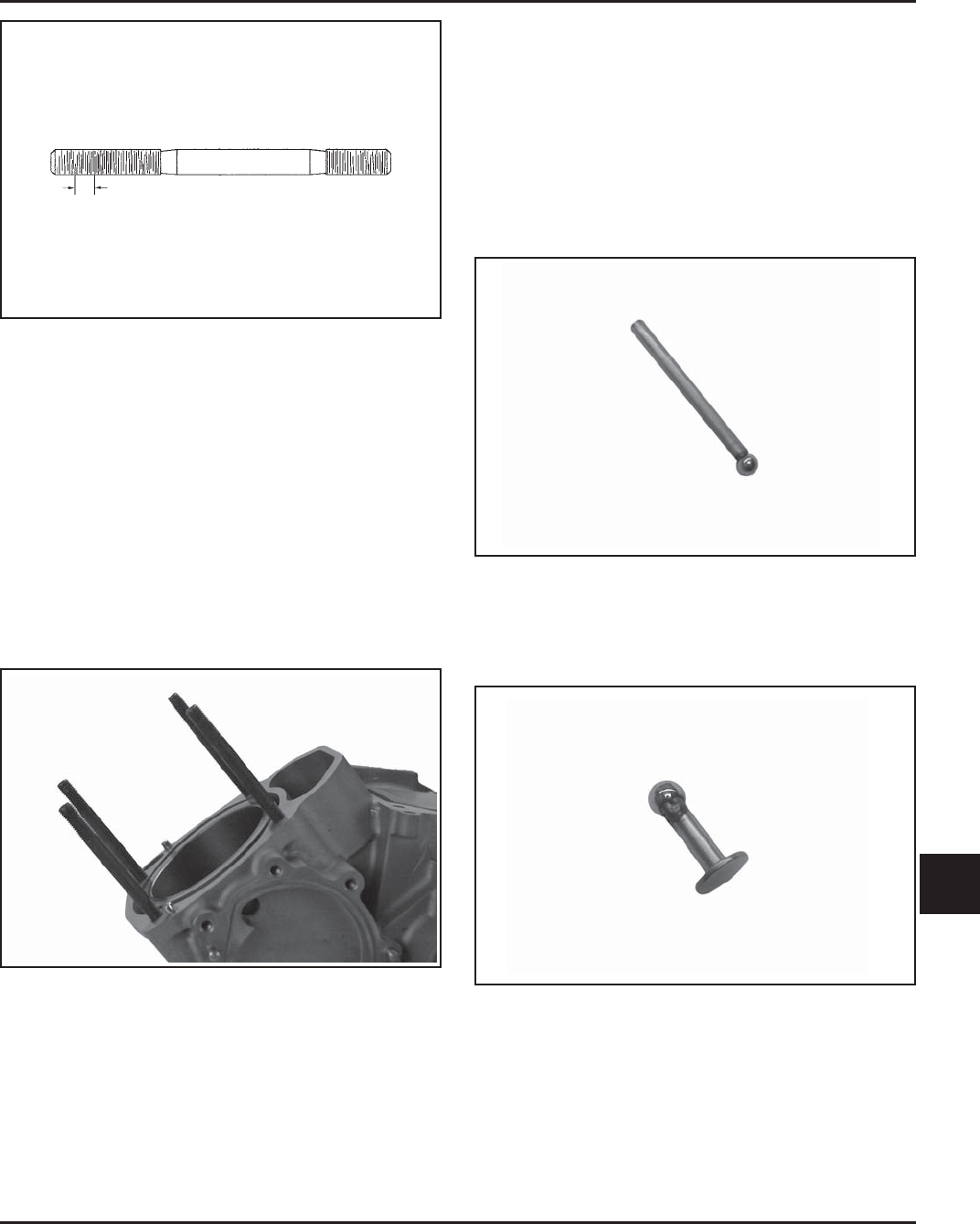

Figure 11-19. Push Rod Tool.

NOTE: Another tool for bleeding may be made

from an old tappet and ball bearing

welded together. See Figure 11-20.

Figure 11-20. Tappet and Ball Bearing Welded

Together.

2. Lightly lubricate the bottoms of the lifters with oil

and install into their respective bores. Do not

prime the lifters.

NOTE: Hydraulic lifters should always be

installed in the same position as before

disassembly.