3-56 DISASSEMBLY, REASSEMBLY, INSPECTION, AND MAINTENANCE

Crankshaft

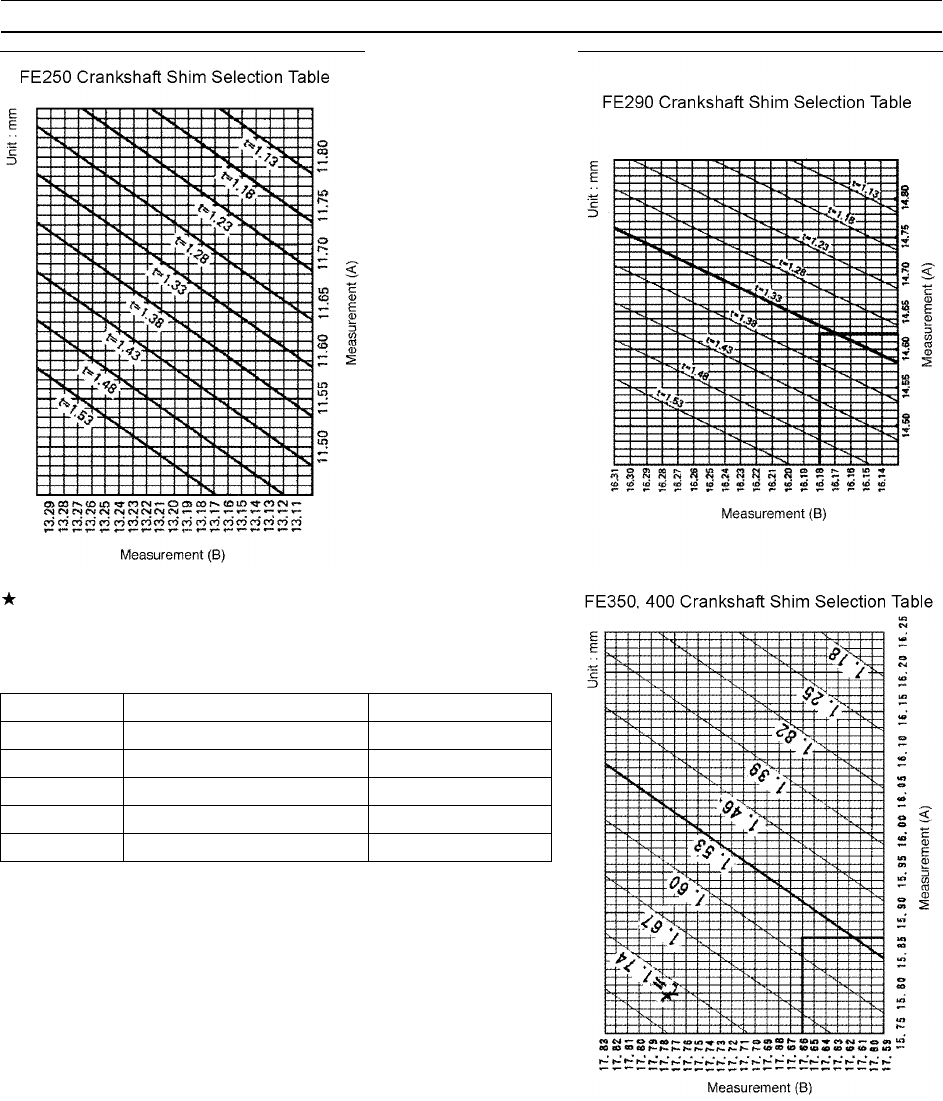

For example, on the FE350, if measurement [A] is 15.87 mm and

measurement [B] is 17.66 mm, the correct shim thickness is t = 1.53

mm.

Crankshaft Axial Play Standard and Service Limit (maximum) (unit: mm)

Standard Service Limit

FE120 0 ~ 0.24 (0 ~ 0.009 in) 0.5 (0.0197 in)

FE170 0.03 ~ 0.30 (0.0011 ~ 0.0118 in) 0.5 (0.0197 in)

FE250 0.05 ~ 0.17 (0.0020 ~ 0.0067 in) 0.35 (0.0138 in)

FE290 0.09 ~ 0.20 (0.0035 ~ 0.0079 in) 0.35 (0.0138 in)

FE350, 400 0.08 ~ 0.22 (0.0031 ~ 0.0087 in) 0.35 (0.0138 in)

Reassembly

The reassembly is the reverse order of disassembly.

•

Clean the mating surfaces of the crankcase and the crankcase cover

of any residues and install a new gasket.

•

Apply high-temperature grease to the lip of the crankcase oil seal.

(Refer to the section on Oil Seal.) Apply oil to the journals of each

part.

•

On the FE221 ~ 400 with a reciprocal movement balancer, install the

reciprocal movement balancer parts on the crankshaft. (Refer to the

section on Balancer.)

•

Install the crankshaft in the crankcase, making sure not to damage the

oil seal lip with the key groove at the tapered area of the crankshaft.