F8QT ENGINE -

Crankshaft and Cylinder Block

11A-23-3

INSTALLATION SERVICE POINTS

"

A

A

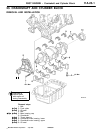

THRUST WASHER INSTALLATION

(1) Fit the thrust washers

7

at No. 2 journal on the crankshaft

6

.

Caution

D

Fit the thrust washers 7 with the oil grooves A

facing outwards.

"

B

A

CRANKSHAFT MAIN BEARING / MAIN BEARING

CAPS INSTALLATION

Caution

D

The main bearing caps are marked.

(1) Start by installing bearing cap No. 2. The bolts should

be tightened to the specified torque.

(2) Check that the crankshaft rotates smoothly.

(3) Move the crankshaft backwards a nd forwards in the

longitudinal direction and check whether the end play

is within the specified tolerance range.

(4) Fit the bearing cap in the cylinder block so that the mating

faces are positioned about 10 mm away from each other.

(5) Centre the bearing cap with the two socket-head screws.

(6) Pack the two recesses in the bearing cap with sealant.

NOTE

The two recesses should be filled down to the bottom

edge.

(7) Tighten the two socket-head screws to the specified

torque.

Remove excessive sealant.

"

C

A

FRONT PLATE INSTALLATION

(1) Apply an even, uninterrupted bead of sealant to the front

plate. (Maximum bead width 2 mm).

Caution

D

Make sure that the surface to which the sealant

is applied is free of dirt and other impurities.

D

Check that the two fitted sleeves are present.

PWEE9602

E

July 1996Mitsubishi Motors Corporation

REN0130

REN0131

65 Nm

REN0132

REN0133

65Nm

10 mm

REN0134