F8QT ENGINE -

Fuel Injection Nozzle

11A-18-3

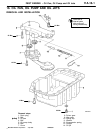

Leakage test

(1) Increase the pressure to 11 MPa by operating the lever

of the nozzle tester. Maintain the pressure for 10 seconds.

No fuel must dribble out of the nozzle during this test.

(2) If dribbling startswithin this 10 secondperiod, disassemble

and clean the injection nozzle

3

and repeat the test. Fit

a new injection nozzle if the problem persists.

REMOVAL SERVICE POINTS

A

A

"

FUEL INJECTION NOZZLE DISASSEMBLY

Caution

D

Remove any carbon deposits from the injectionnozzle

3 before starting disassembly, assembly and

adjustment. Before disassembly, test the fuelinjection

nozzle for abnormal injection pressure, abnormal

spray pattern and leakage. If the fuel injection nozzle

is operating correctly, it does not have to be

disassembled.

A

B

"

NEEDLE VALVE / NOZZLE TIP REMOVAL

Caution

D

Do not touch the sliding surface A of the needle valve

10.

D

Make sure that the original combination of needle

valve 10 and nozzle tip 11 are reassembled.

CLEANING

NEEDLE VALVE / NOZZLE TIP

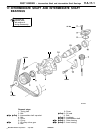

(1) Wash the removed needle valve

10

and nozzle tip

11

in clean paraffin and remove any carbon deposits with

the tool. Proceed as follows:

(a) Remove the carbon deposits on the tip of the needle

valve

10

with t he small cleaning rod

B

(special tool).

Caution

D

Do not use a wire brush of other hard metal

tools for cleaning.

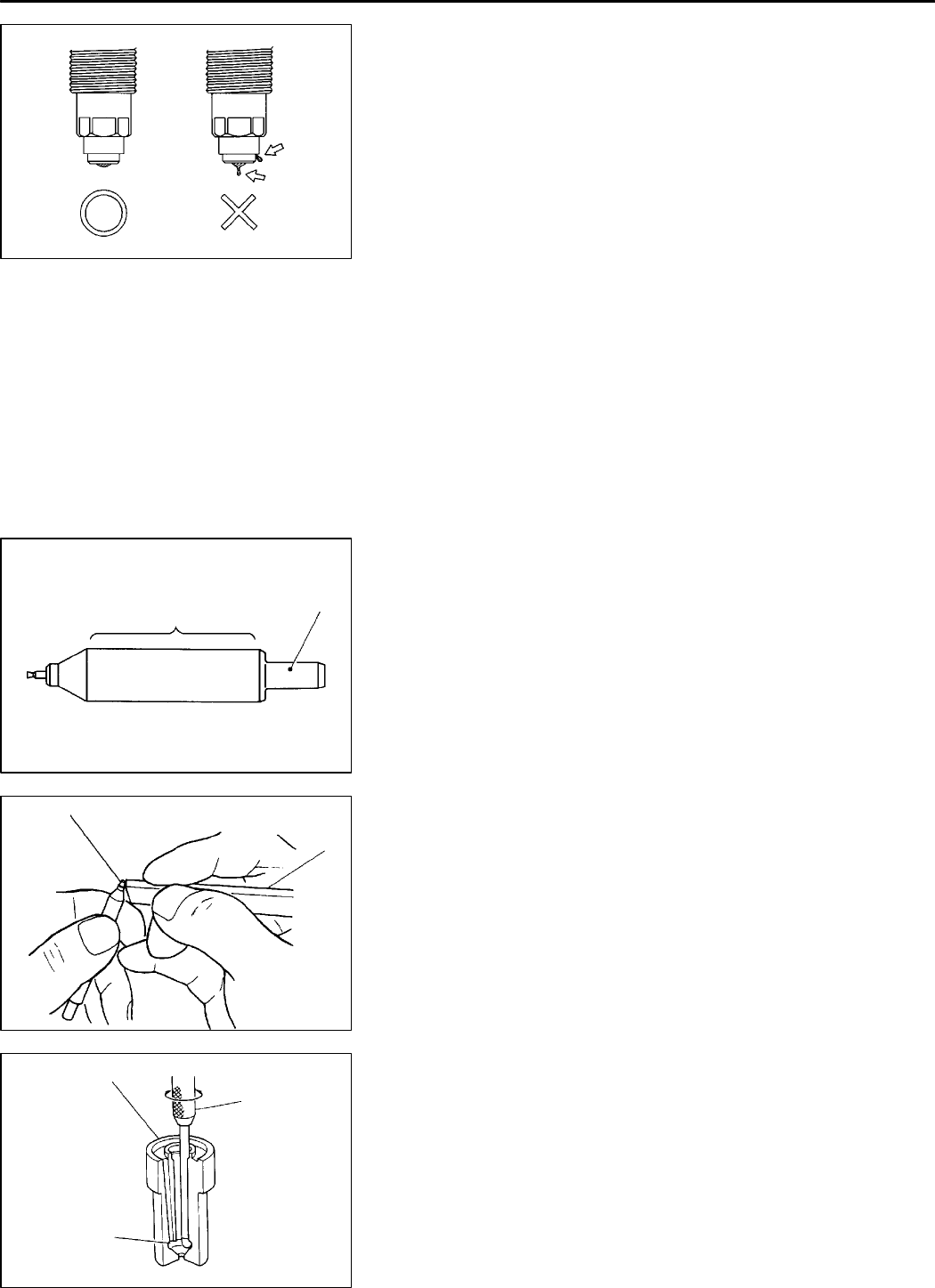

(b) Remove the carbon deposits in the oil hole

C

of the

nozzle tip

11

with the scraper tool

D

.

PWEE9602

E

July 1996Mitsubishi Motors Corporation

4ME0208

4ME0209

10

A

4ME0210

10

B

4ME0211

11

D

C