F8QT ENGINE -

Pistons and Piston Pins

11A-21-3

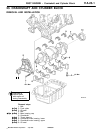

CURVATURE AND TWIST OF CONNECTING ROD

(1) Measure the curvature and the twist of the connecting

rod

3

.

Replace t h e connecting rod if the limit values are

exceeded.

Caution

D

Installed connecting rod 3, with upper and lower

connecting rod bearings in place, in the

connecting rod alignment tool.

D

Tighten the connecting rod cap in accordance

with the specified procedure.

INSTALLATION SERVICE POINTS

"

A

A

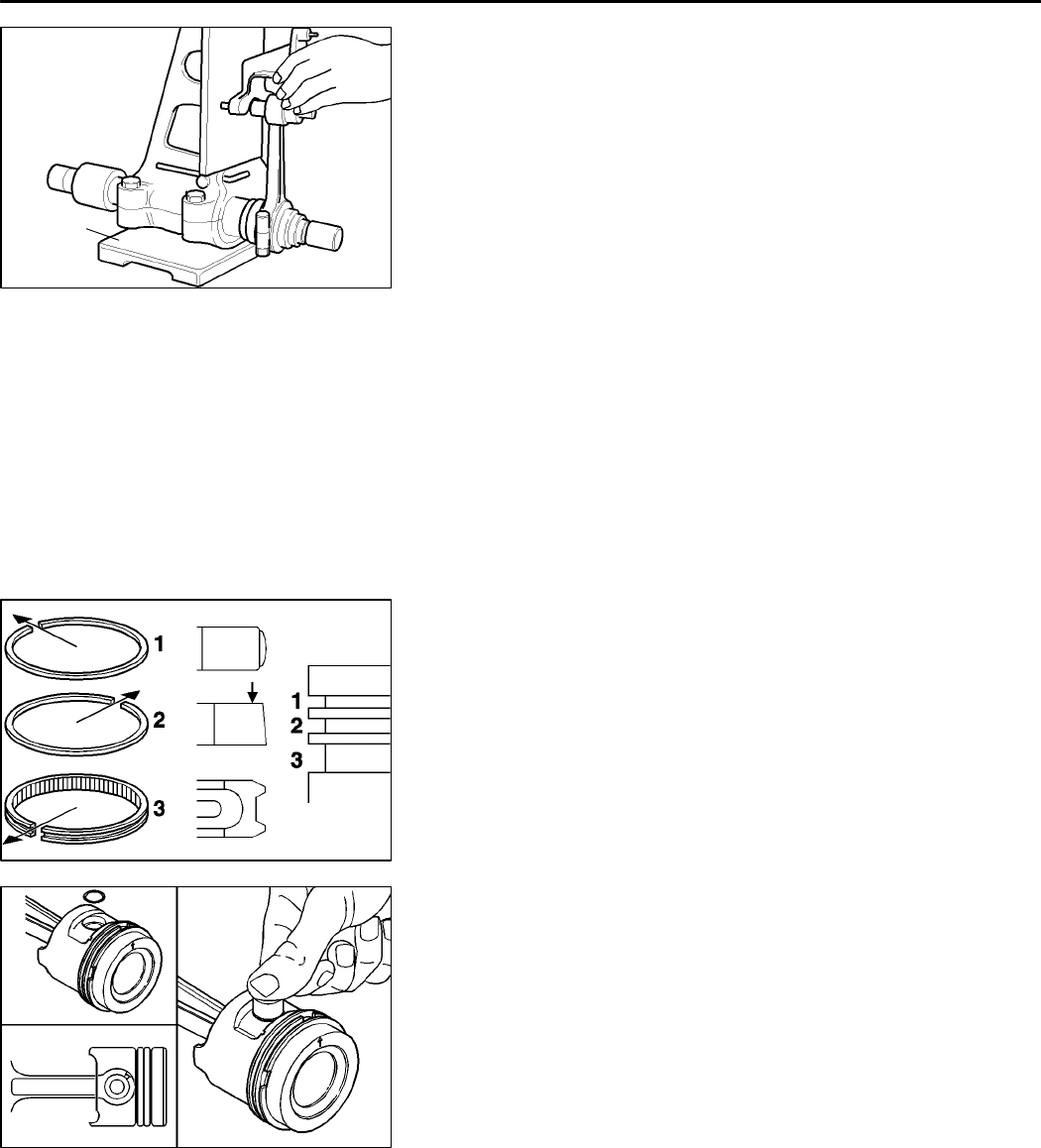

PISTON RING INSTALLATION

(1) Fit the oil ring

6

.

(2) Fit the No. 2 piston ring

5

.

(3) Fit the No. 1 piston ring

4

.

Lubricate the piston rings with engine oil.

Position the piston ring gaps at an angle of 120_ to each

other.

"

B

A

PISTON PIN INSTALLATION

(1) Fit the circlip in the piston

7

.

(2) Smear a thin layer of engine oil on the piston pin

2

before

fitting. Install the connecting rod

3

with the oil passage

facing away from the combustion chamber in the piston.

(3) Insert t he piston pin.

(4) Fit the circlip in the piston

7

.

PWEE9602

E

July 1996Mitsubishi Motors Corporation

REN0118

Alignment

gauge

REN0113

Top

REN0119