47

Reference Manual

00809-1600-4530, Rev AA

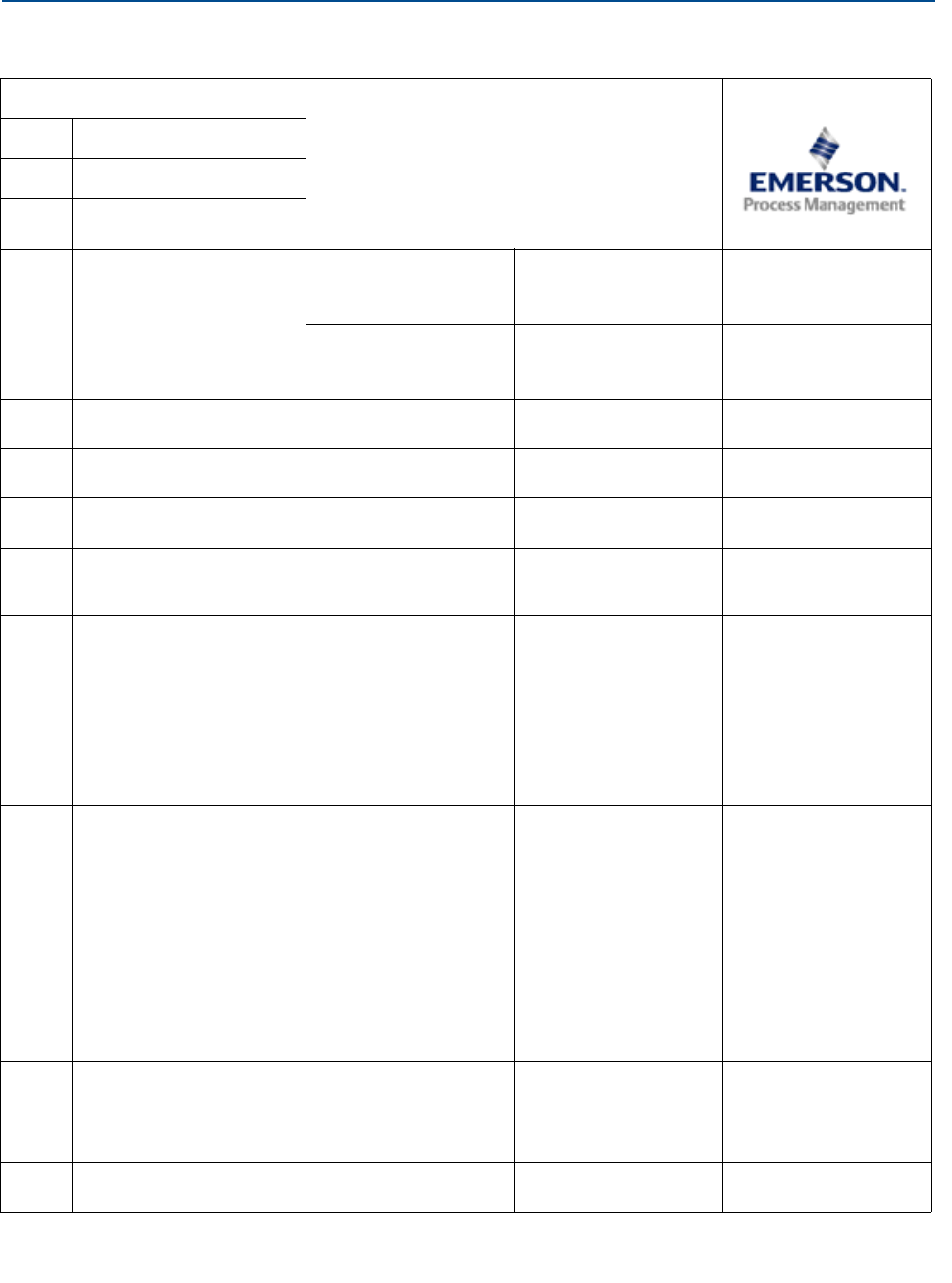

Appendix A: Commissioning Checklist

March 2015

Commissioning Checklist

A.4 GWR radar verification in chambers

UNIT:

Note: Verification procedure is performed under

ambient conditions. For dynamic vapor

compensations units, ensure that the DC is calculated

at 1.0 before starting verification process. If static

vapor compensation is used, set vapor DC to 1 for the

test and reset to desired value when finished. For all

other units, vapor DC should be set at 1.

DATE:

TIME:

TECH:

STEP TASK

DEVICE TAG:

__________________

DEVICE TAG:

__________________

DEVICE TAG:

__________________

SERIAL NUMBER:

__________________

SERIAL NUMBER:

__________________

SERIAL NUMBER:

__________________

1

Isolate chamber using upper

and lower block valves

YES NO YES NO YES NO

2

Vent chamber using upper

vent valves

YES NO YES NO YES NO

3

Open bottom vent valves

and connect water source

YES NO YES NO YES NO

4

Open up echo curve and

start continuous record

mode

**Leave in continuous

record mode

throughout test**

**Leave in continuous

record mode

throughout test**

**Leave in continuous

record mode

throughout test**

5

Verification at zero (LRV -

4mA)

Radar Output (Level):

____________________

Radar Output (mA):

__________________

DCS Reading:

__________________

Radar Output (Level):

____________________

Radar Output (mA):

__________________

DCS Reading:

__________________

Radar Output (Level):

____________________

Radar Output (mA):

__________________

DCS Reading:

__________________

6

Verification at nominal level

condition

Radar Output (Level):

____________________

Radar Output (mA):

__________________

DCS Reading:

__________________

Radar Output (Level):

____________________

Radar Output (mA):

__________________

DCS Reading:

__________________

Radar Output (Level):

____________________

Radar Output (mA):

____________________

DCS Reading:

____________________

7

DCS (zero check - bias

added)

DCS Reading - (w/ Bias):

____________________

DCS Reading - (w/ Bias):

____________________

DCS Reading - (w/ Bias):

____________________

8

Trim gauges to read

identical levels (if needed)

Enter “Calibration

Offset” values in gauges

as required to bring

them all to identical level

readings

Enter “Calibration

Offset” values in gauges

as required to bring

them all to identical level

readings

Enter “Calibration

Offset” values in gauges

as required to bring

them all to identical level

readings

9

View echo curve and make

threshold adjustments

**Adjust only if

needed**

**Adjust only if

needed**

**Adjust only if

needed**