30

Reference Manual

00809-1600-4530, Rev AA

Section 4: Verification Procedure with Fluid

March 2015

Verification Procedure with Fluid

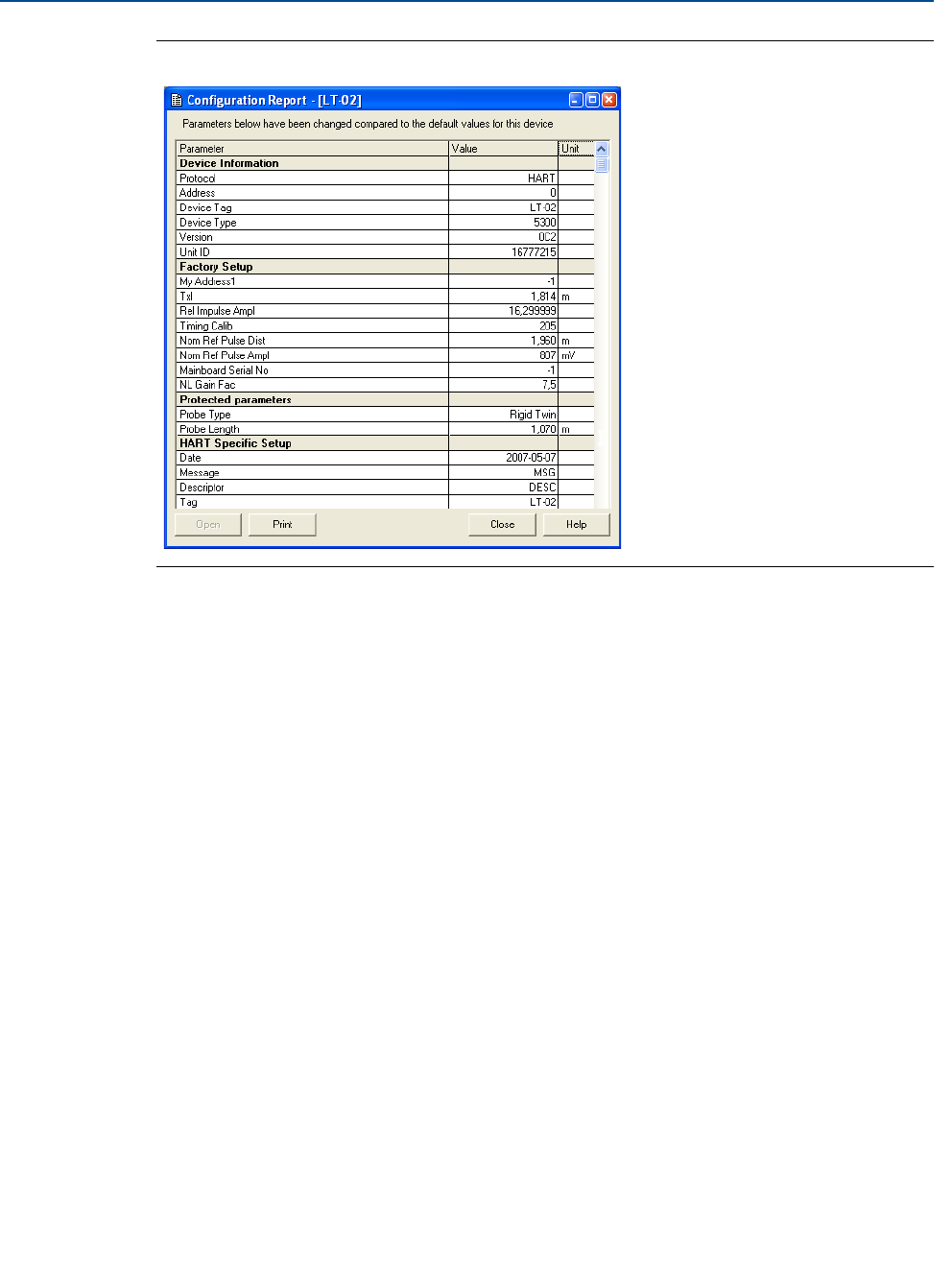

Figure 4-9. The Configuration Report Window in RRM

4.7.1 Other validation suggestions

To validate a device, do one of the following:

Check the end of probe peak and label when the vessel or chamber is completely

empty. Check if the peak corresponds to the EOP label. If it does not correspond, check

the probe length that was used in the configuration.

Check if there is an alternative measurement. Compare it to the GWR result. An

Magnetic Level Indicator (MLI) can be used, but with the caveat that the MLI is

density-dependent. For example, if the MLI float is sized to be used with oil, but the

validation is completed with water, the MLI and the GWR will be offset. The GWR will

track the surface regardless of the fluid density.

If the verification reflector is present, check its location to validate a reading after the

reflector calibration is complete.

Check if SQM is used. On a clean probe and a high dielectric fluid, the signal quality

value should be high (>8).

For an interface measurement, use an alternative way to know the interface, for

example a sight-glass. The DC of the upper fluid may need to be adjusted to make the

interface given by the GWR match the interface from the sight glass. The dielectric

calculator tool in RRM can be used to assist with this adjustment.