23

Reference Manual

00809-1600-4530, Rev AA

Section 4: Verification Procedure with Fluid

March 2015

Verification Procedure with Fluid

Section 4 Verification Procedure with

Fluid

Verification procedure with active level measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Common problems and recommended actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 25

Transmitter diagnostics review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Monitor level while emptying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 27

Echo curve verification with empty tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Monitor level while filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

Archive files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 29

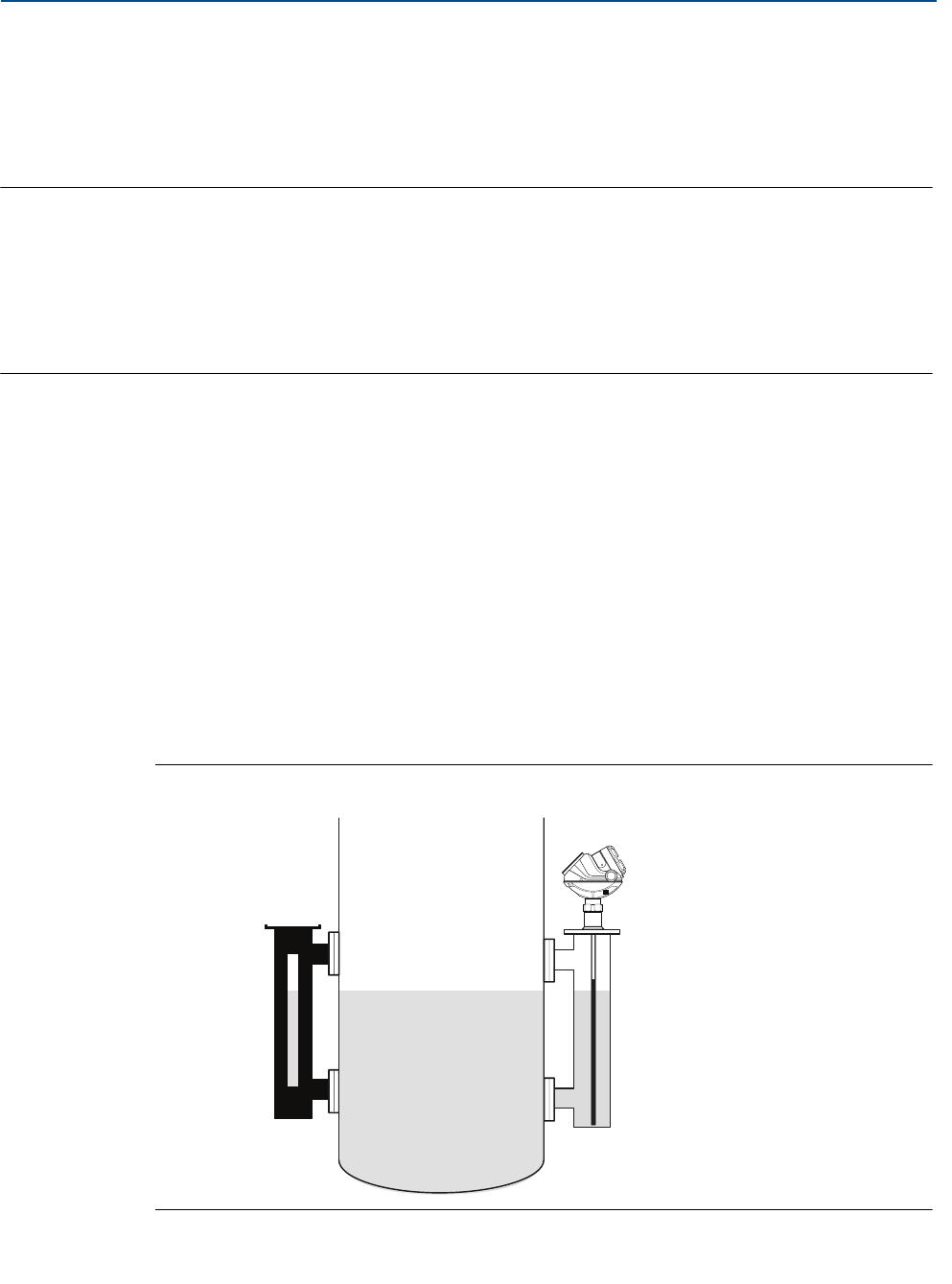

4.1 Verification procedure with active level

measurement

At normal operating conditions, compare the transmitter level, or interface reading, with an

independent measurement. Unfortunately, it often happens that two independent

measurements do not match up perfectly, but check the sanity and the acceptable deviation.

Verify the correctness of level reading

The independent measurement can be done using a number of different complementary

devices, ranging from sight-glasses and hand-dipping to redundant differential pressure and

displacer transmitters.

Figure 4-1. The Verification of Measurement Data Using a Sight-glass