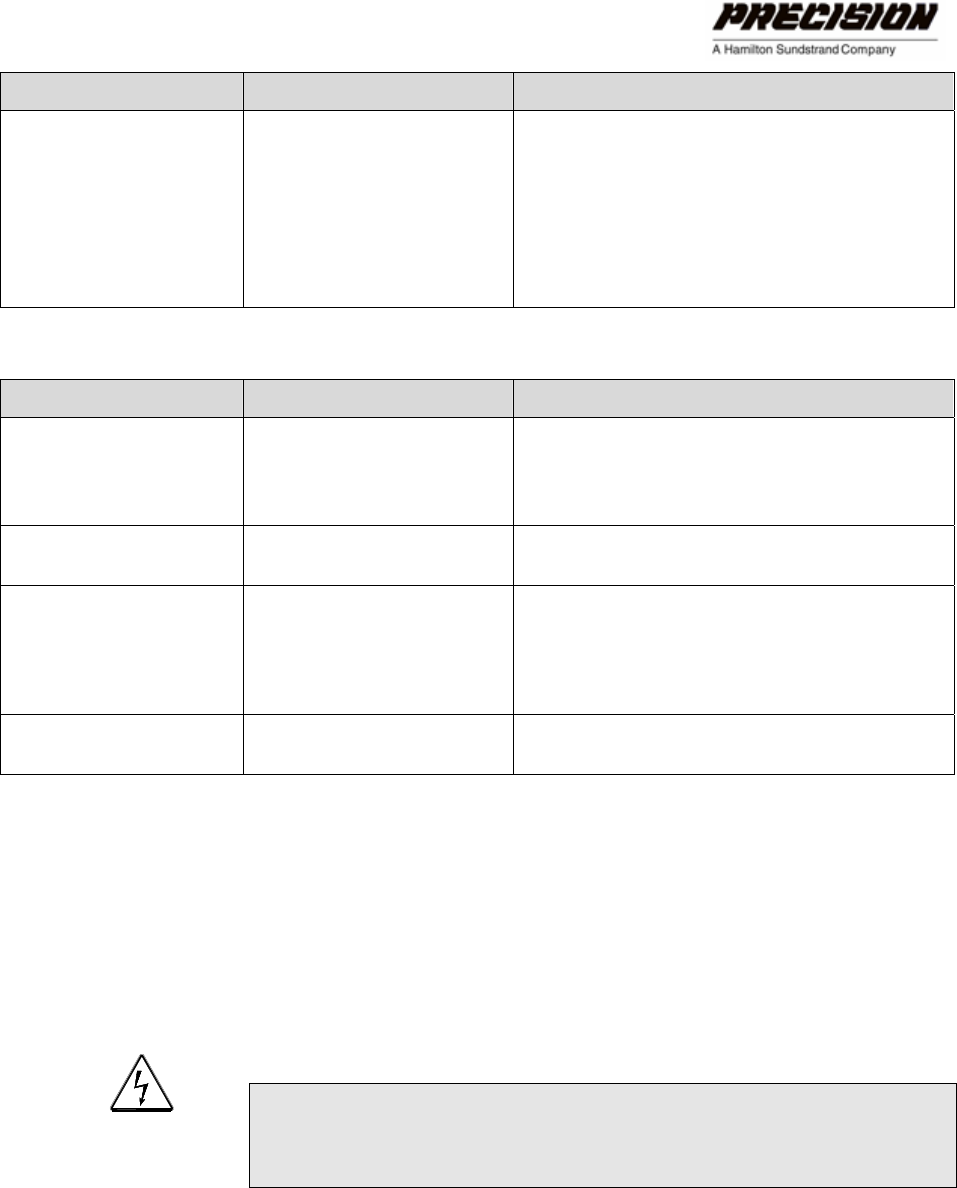

Symptom Probable Causes Corrective Action

RS232 Interface Inoperative Incorrect wiring

No or low 120 VDC power

COM1 not connected

RESET or RUN command is

ON

Ensure WHITE/ORANGE/YELLOW,

WHITE/ORANGE/BLUE, WHITE/ORANGE/GREEN

wires correctly connected to valve and laptop PC.

Ensure 120 VDC Primary System Power at Valve

Check laptop/PC com port

Remove RESET or RUN command

Table 5-1. Initial Installation Troubleshooting Chart

Symptom Probable Causes Corrective Action

No valve feedback No or low 120 VDC power

Self-protective valve auto shut

down

Ensure 120 VDC at valve

Upload Fault File- check for motor windings over -

temperature faults.

Check for valve contamination

FAULT alarm Various Upload Fault File to identify source of fault

Clear indicated fault

OVER TEMP alarm Ambient temperature limit

exceeded

Electronics or motor winding

temperature out of range

Allow actuator to cool and re-start

Reduce ambient temperature

Check for valve contamination

FAULT and OVERTEMP

alarm

No 120 VDC Power

DSP Failure

Ensure 120 VDC at actuator

Contact factory

Table 5-2. HFG2.0 In-Service Troubleshooting Chart

For troubleshooting purposes, use Table 5-3 to verify the valve electrical

continuity integrity.

Disconnect the HFG2.0 power and digital harness connectors and use a

digital multi-meter (DMM) to check the resistance values between the

wires indicated on the table. If an open circuit is detected, send the

HFG2.0 to Precision Engine Controls Corporation for test and repair.

WARNING – Shock Hazard

Remove all power to the HFG2.0 prior to continuity check.

CH. 4: TROUBLESHOOTING THE HFG2.0 57