CI-ControlWave EFM Appendix F / F-25

F.6.2.2 Frequency Input

The frequency input must be brought into one of the two high-speed counter (HSC) inputs

on the I/O board. Users select the two I/O points to which the typical turbine, PD, or

ultrasonic meter is connected. However; if using an Invensys Auto-Adjust Turbo-Meter,

both HSC inputs are used to select the Auto-Adjust Algorithm. To select the Auto-Adjust

Algorithm, the user will toggle the push button under Source

fromr High Speed Counter to

Auto Adjust Module

. In this case, the user selects which point will be used for the Main

Rotor and which point will be used for the Sense Rotor.

Further configuration of the Auto-Adjust Turbine Meter is performed via the Auto-Adjust

Configuration Page. (For a description of the items on the Auto-Adjust Configuration Page,

see the ACCOL3 Function Block Help Documentation).

If the user selects the Auto-Adjust Configuration button the Auto-Adjust Configuration for

Run # Web Page will appear (see Figure F-16B). This page provides Calibration Data,

Configuration Data and Calculated Factors.

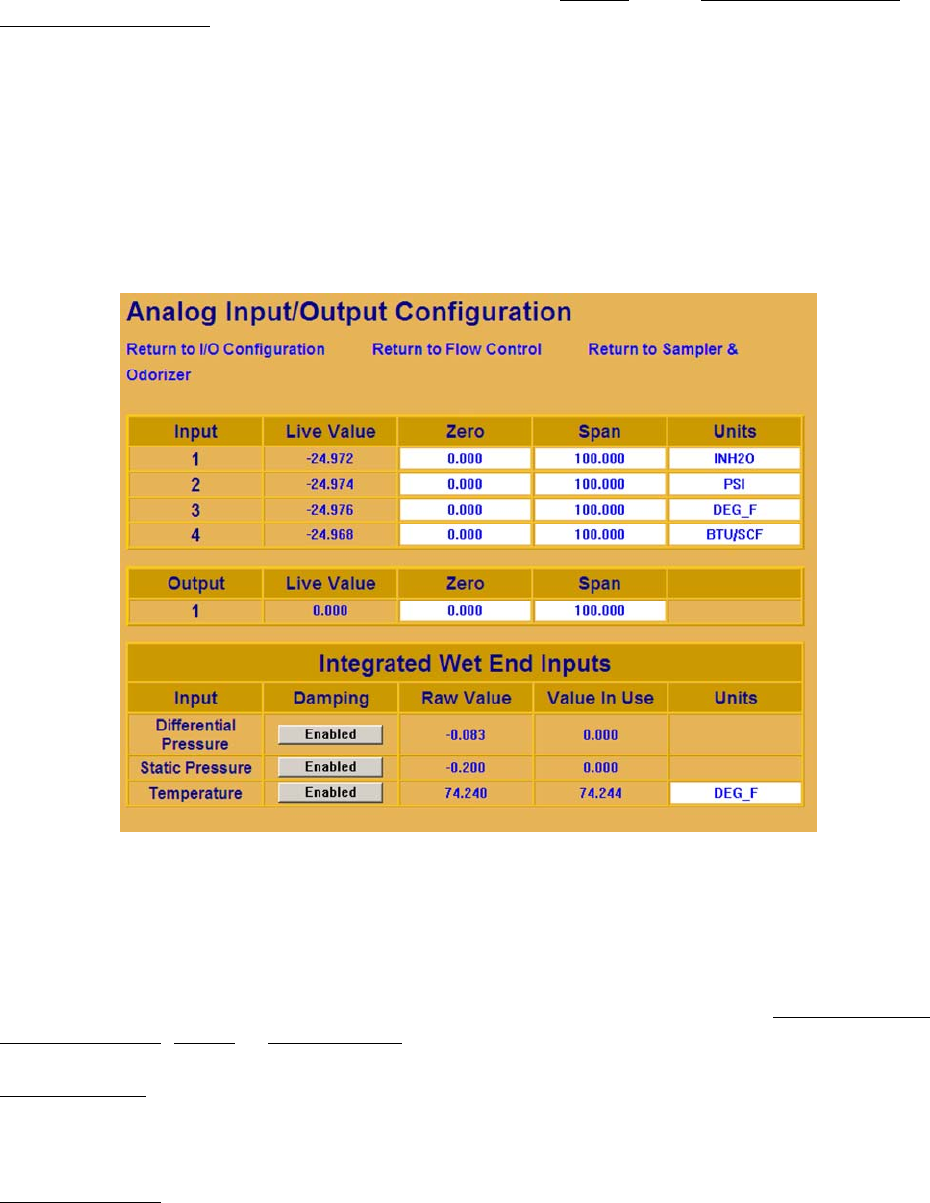

Figure F-16A - Analog Input Configuration Web Page

(Accessed from Meter Run I/O Configuration Web Page)

F.6.2.3 Heating Value Input

The user has four options for the source of the heating value, Manual Entry

,

Chromatograph

, AGA5 or Analog Input.

Manual Entry

is selected when the heating value will be directly entered. This value may

be entered via the Meter Run I/O Configuration Web Page, or may be written to a signal

externally.

Chromatograph

is selected when the heating value is read directly from the chromatograph

via the MODBUS interface.