74

Beck drives require only a minimum of routine

maintenance. A visual inspection is in order

to verify that the connection to the final control

element is intact and operating normally. If

vibration is present, check the electrical terminal

connections and other hardware for tightness.

LUBRICATION

Periodic lubrication is not required on Beck

control drives. However, it is recommended that

during major shutdowns or outages, the drives

in the most severe applications be inspected to

determine the need to relubricate the drive gear

train.

If your drive has a linkage, to extend the life of

the linkage rod ends, they should be included in

your scheduled lubrication program.

CAUTION

If your drive has a linkage, before removing

the gear module assembly, block the control

drive crank arm to prevent the crank arm and

the gear train from moving when the change

module is removed.

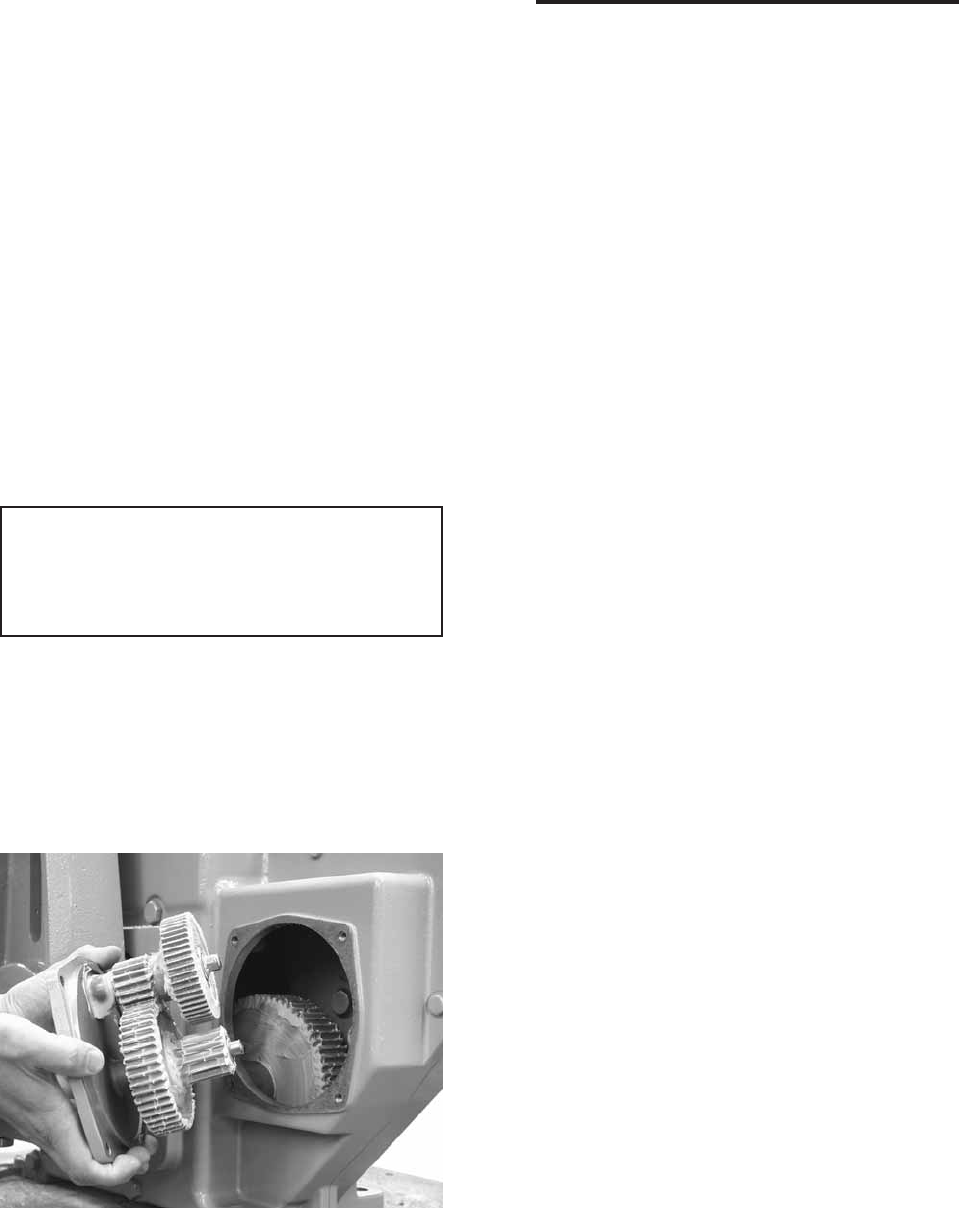

To inspect the gears, remove the gear module

assembly on the 11-209/-269, -309/-369 and

-409/-469. On Model 11-159/-169, the motor

must be removed to access the gears. Clean the

gears thoroughly, removing all old lubrication.

MAINTENANCE ROUTINE

11-409 Gear Module

Examine the gear teeth, shaft bore, and

gear shafts for signs of excessive wear, scoring,

or other damage. If evidence of this damage

is present, the drive should be returned to the

factory for a detailed examination of the main

gear, which requires complete disassembly of

the drive. See "HOW TO OBTAIN SERVICE" on

page 87.

If there is no evidence of damage to the

gearing, recoat the teeth and shaft bores of all

gears with a heavy layer of Fiske Lubriplate GR-

132 or equivalent (GR-132 is an E.P. grease with

polymer additives). The ball bearing on the output

shaft and crown gear shaft have added double

grease seals and require no maintenance for the

life of the bearings. Inspect all grease seals and

replace any that show wear. Reassemble the

drive, referencing pages 8–14 for appropriate

bolt torques.