19

START-UP INSTRUCTIONS

After the drive is mounted and its wiring

connections are made, it is ready to be tested for

proper operation.

NOTE: All Beck drives are shipped from the

factory ready for installation; no electrical

adjustments are required before placing

them in operation. Each drive is set up and

calibrated to the customer’s specifications that

were written into the equipment order.

Turn on the power supply. Operate the drive

with the Handswitch and run it through its full stroke,

both directions. Observe that the driven device

travels through its desired stroke. If satisfactory,

set Handswitch to the “AUTO” position.

Turn on the controller and operate the drive by

varying the control signal. Check that the damper

or valve strokes in the proper direction for a change

in control signal. If it does not, first check for proper

wiring connections and verify control signal at the

drive. If the wiring is correct, then change the

direction of output shaft rotation (see applicable

instructions on page 31, 51 or 69).

in the field (see Table 1, below, for instructions to

calculate pipe length). To simplify installation of the

pipe link, the kit accepts NPT right-hand threads

on both ends of the pipe. Left-hand threads are

internal to the linkage kit assembly, making final

length adjustments quick and easy.

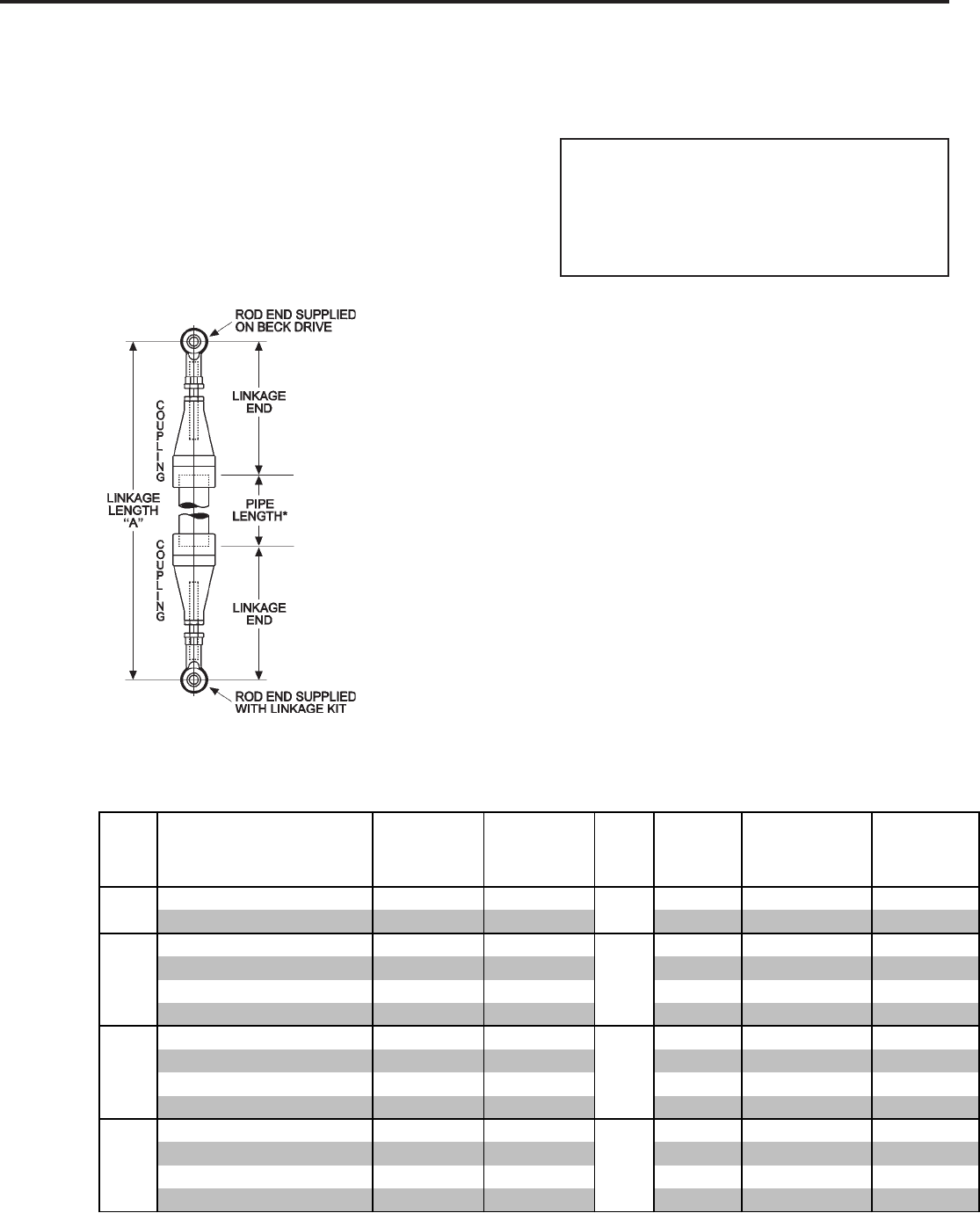

To order pipe linkage kits, first obtain the

approximate overall linkage length “A” in the figure

below. Select the kit part number from Table 1,

below. For lengths beyond those listed in the table,

contact your Beck sales engineer.

TABLE 1:

PIPE LINKAGE KITS

*NOTE: To calculate

length of pipe required,

subtract “Length

of 2 Linkage Ends”

(shown in Table 1)

from Linkage Length

“A” (shown at left).

Beck Rod Length of 2

Drive Linkage Min. Pipe End Beck Pipe Linkage Ends

Model Length Pipe Nipple Thread Linkage Kit (Total Adj. Approx.

No. Range "A" Size Length (UNF) Part No. ±1 1/2"(38 mm)) Weight

11-159

22–84" (559–2 134 mm) 1" (25 mm) 1 1/2" (38 mm)

1/2-20

20-1730-05 20 1/2" (521 mm) 5 lbs (2 kg)

31–120" (787–3 048 mm) 1 1/2" (38 mm) 1 3/4" (44 mm) 20-1740-06 29 1/4" (743 mm) 9 lbs (4 kg)

11-209

22–45" (559–1 143 mm) 1" (25 mm) 1 1/2" (38 mm)

1/2-20

20-1730-05 20 1/2" (521 mm) 5 lbs (2 kg)

31–84" (787–2 134 mm) 1 1/2" (38 mm) 1 3/4" (44 mm) 20-1740-06 29 1/4" (743 mm) 9 lbs (4 kg)

33 1/4–120" (845–3 048 mm) 2" (51 mm) 2" (51 mm) 20-1750-05 31 1/4" (794 mm) 13 lbs (6 kg)

37–120" (940–3 048 mm) 2 1/2" (64 mm) 2 1/2" (64 mm) 20-1760-05 34 1/2" (876 mm) 22 lbs (10 kg)

11-309

22 1/2–36" (572–914 mm) 1" (25 mm) 1 1/2" (38 mm)

5/8-18

20-1730-06 21" (533 mm) 5 lbs (2 kg)

31 1/2–72" (800–1 829 mm) 1 1/2" (38 mm) 1 3/4" (44 mm) 20-1740-07 29 3/4" (756 mm) 9 lbs (4 kg)

33 3/4–96" (857–2 438 mm) 2" (51 mm) 2" (51 mm) 20-1750-06 31 3/4" (806 mm) 13 lbs (6 kg)

37 1/2–120" (953–3 048 mm) 2 1/2" (64 mm) 2 1/2" (64 mm) 20-1760-06 35" (889 mm) 22 lbs (10 kg)

11-409

23 1/4–34" (590–864 mm) 1" (25 mm) 1 1/2" (38 mm)

3/4-16

20-1730-07 21 3/4" (552 mm) 5 lbs (2 kg)

32 1/4–48" (819–1 219 mm) 1 1/2" (38 mm) 1 3/4" (44 mm) 20-1740-08 30 1/2" (775 mm) 9 lbs (4 kg)

34 1/2–72" (876–1 829 mm) 2" (51 mm) 2" (51 mm) 20-1750-07 32 1/2" (826 mm) 13 lbs (6 kg)

38 1/4–120" (972–3 048 mm) 2 1/2" (64 mm) 2 1/2" (64 mm) 20-1760-07 35 3/4" (908 mm) 22 lbs (10 kg)