5

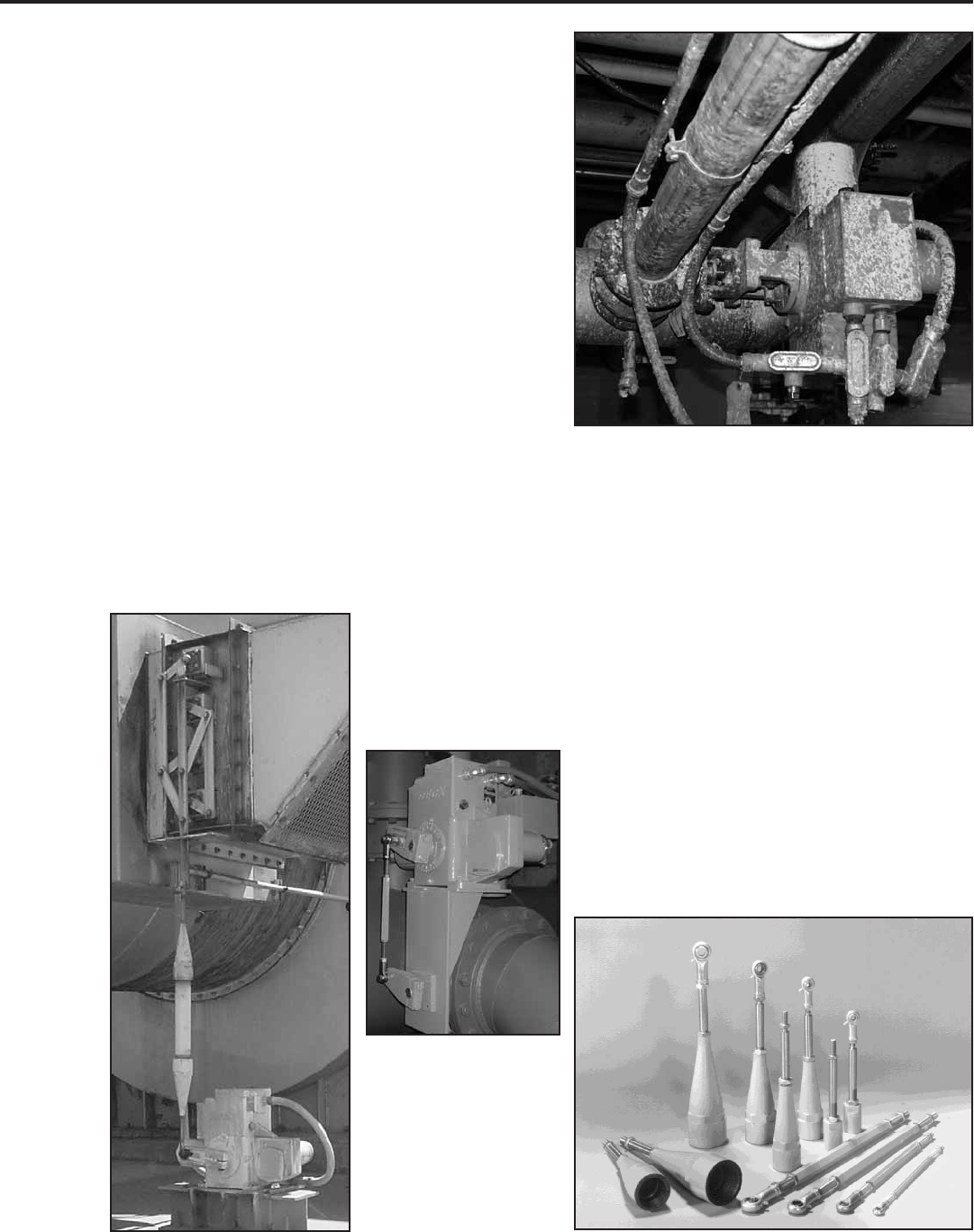

TYPICAL APPLICATIONS

Beck control drives are ideally suited for use on

ball, plug and butterfly valves, as well as dampers

and fluid drives. When equipped with a sheave

and multi-turn option (consult your Beck Sales

Engineer for details), the drive can be used to raise

and lower a weight-balanced damper.

DCM-2 equipped Beck drives are designed for

precise position control in modulating applications.

The drive is best utilized when its full travel is

employed to achieve its greatest sensitivity and

resolution, although the driven device may operate

through a considerably smaller range. Beck drives

can be configured with special linkage to deliver

greater torque where needed, so that drive size

and resultant cost can be minimized.

Valves can be furnished by Beck as unitized

assemblies with control drives mounted and

tested in the factory. Depending on the valve

and application, valves can be mounted directly

or using a bracket and linkage. Also, drives may

be installed in the field with mounting hardware

furnished by Beck or the customer. Drives for

dampers are generally installed at the site on a

mounting platform separate from the damper.

BECK LINKAGE KITS

Beck hex and pipe linkage kits are available

for completing the mechanical connection from the

drive crank arm to the load. Through the use of a

standardized selection, the linkage can be ordered

even if the exact length is not determined until the

drive and driven device are installed.

All Beck foot-mounted drives are furnished

with a crank arm and rod end (see pages 8, 10

and 13 for dimensions). All rod ends furnished

by Beck incorporate bearings to accommodate

some lateral misalignment. Once the connection

is made, linkage kits can be adjusted ±1 1/2”

(38 mm) without removal of the crank arm or load

lever, making final mechanical calibration simple.