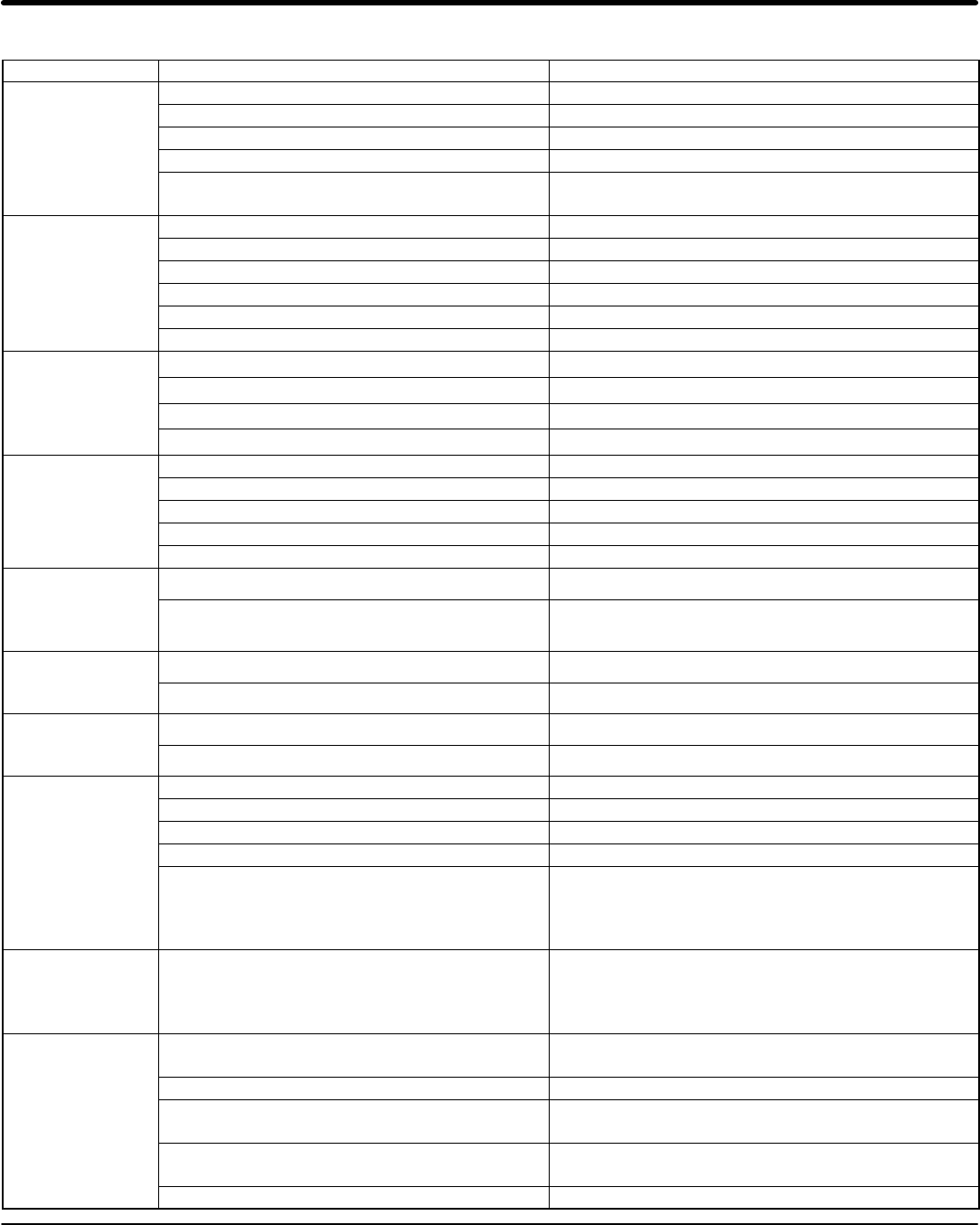

5-6 Troubleshooting MN894

Table 5-3 Troubleshooting Chart

Symptom Cause Corrective Action

Motor is not connected. Connect motor to T1, T2 and T3 of control.

MCP trips as it is

ST contact on control is always closed. Repair or replace logic control module.

MCP trips as it is

closed (also see

Improper input voltage. Obtain the correct source voltage at L1, L2 and L3.

c osed (a so see

Shunt Trip light

ON)

Shorted SCR. Replace SCR or power cell.

pg

comes ON)

Control transformer (if equipped) set for wrong

voltage.

Change tap connections for correct voltage.

MCP t i th

MCP trip setting is too low. Increase MCP Trip setting.

MCP trips as the

motor is started

Line voltage decreases during motor starting. Fix incoming power problem.

motor is started

(also see Shunt

Motor or wiring is defective. Check terminal and motor wiring.

(

a

l

so

see

Sh

un

t

Trip light comes

Capacitors on output of control. Remove capacitors or move to line side of control.

Trip light comes

O

N

)

Logic control module is defective. Replace logic control module.

ON)

Improper current calibration. Verify S1 settings for motor nameplate FLA rating.

MCP trips after

th t i

PF set too high. Reduce PF adjustment (rotate CCW).

p

the motor is

running (also see

Occasional line imbalance. Set S2-6 =ON to disable shunt trip while running.

runn

i

ng

(

a

l

so

see

Shunt Tri

p

li

g

ht

Ground or motor fault. Check motor wiring.

Shunt Trip light

comes ON)

S2-6=ON but no bypass contactor is installed. Check setting of S2-6. Should be Off.

Starter does

No line voltage. Restore line voltage.

Starter does

nothing when

Overload is open. Reset overload.

no

thi

ng

w

h

en

start button is

No contact closure across terminals 12 and 13. Check start circuit.

start button is

pressed.

Current trip occurs. Check S1 settings for correct current calibration.

pressed

.

Control module has no power. Check control transformer jumper.

Control does not

accelerate motor

CL set too low. Increase CL adjustment (rotate CW).

acce

l

era

t

e

mo

t

or

to full speed

(Stalls)

Line voltage decreases to less than minimum

operating voltage during motor starting.

Fix incoming power regulation problem.

Insufficient torque

available from

Improper current feedback. Verify S1 settings for motor nameplate FLA rating.

ava

il

a

bl

e

f

rom

current limit CL.

CL set too low. Increase CL adjustment (rotate CW).

Motor

accelerates too

Ramp up (RU) time set too long. Decrease RU (rotate CCW).

acce

l

era

t

es

t

oo

slowly.

Improper current feedback. Verify S1 settings for motor nameplate FLA rating.

Current limit (CL) set too high. Reduce CL (rotate CCW).

Ramp up time (RU) set too short. Increase RU (rotate CW).

Motor

Initial pulse time (PT) set too long. Reduce PT (rotate CCW).

M

o

t

or

accelerates too

Improper current feedback. Verify S1 settings for motor nameplate FLA rating.

accelerates too

quickly.

Light or no load (is dependent on motor load).

A lightly loaded motor will reach full speed with

low starting current or voltage. Motor may

require the use of a tachometer.

Decrease TU, increase RU or install tachometer.

Motor current

and voltage

oscillates after

start

Power factor correction set too high. Reduce PF setting (rotate CCW) until oscillation

stops.

Line voltage decreases to less than minimum

operating voltage during motor starting.

Fix incoming power regulation problem.

Motor is noisy or

Single phasing due to an open phase. Check wiring and overload heaters.

M

otor

i

s

no

i

sy

or

vibrates when

starting

Single phasing or unbalanced current due to a

non-firing SCR.

Check for shorted SCR and replace.

starting

Single phasing or unbalanced current due to a

defective logic control module.

Repair or replace the logic control module.

Defective motor. Check motor for shorts, opens or grounds.