Start-up 4-3MN894

Tach Feedback Starting

11. Set for ramp up with ramp down as follows:

S2-1 = OFF Ramp down disable

S2-2 = OFF Current monitor

S2-3 = OFF Over current shut down

S2-4 = ON Tachometer enable

S2-5 = OFF Current limit enable

S2-6 = OFF Bypass contactor

Set RU, TU, PT and PF fully CCW.

Set RD and RT at mid point.

12. Set for ramp up with no ramp down as follows:

S2-1 = ON Ramp down disable

S2-2 = OFF Current monitor

S2-3 = OFF Over current shut down

S2-4 = ON Tachometer enable

S2-5 = OFF Current limit enable

S2-6 = OFF Bypass contactor

Set RU, TU, PT and PF fully CCW.

13. Continue with step 14.

WARNING: Be sure the system is properly grounded before applying power.

Do not apply AC power before you ensure that all grounding

instructions have been followed. Electrical shock can cause

serious or fatal injury.

WARNING: Improper operation of control may cause violent motion of the

motor shaft and driven equipment. Be certain that unexpected

motor shaft movement will not cause injury to personnel or damage

to equipment. Certain failure modes of the control can produce

peak torque of several times the rated motor torque.

14. Confirm the Close to Run contact is open.

15. Turn Power ON.

16. Close the Run contact.

17. The motor should just begin to rotate when power is applied and reach Ramp

End in a minimum starting time. The control is properly set if the motor starts

smoothly when power is applied and comes to speed as quickly as possible.

Be sure CL is set high enough so the motor can start with a full load. The

control is finished starting when the Ramp End light is ON.

18. If motor operation is not correct, perform one or more of the following

adjustments:

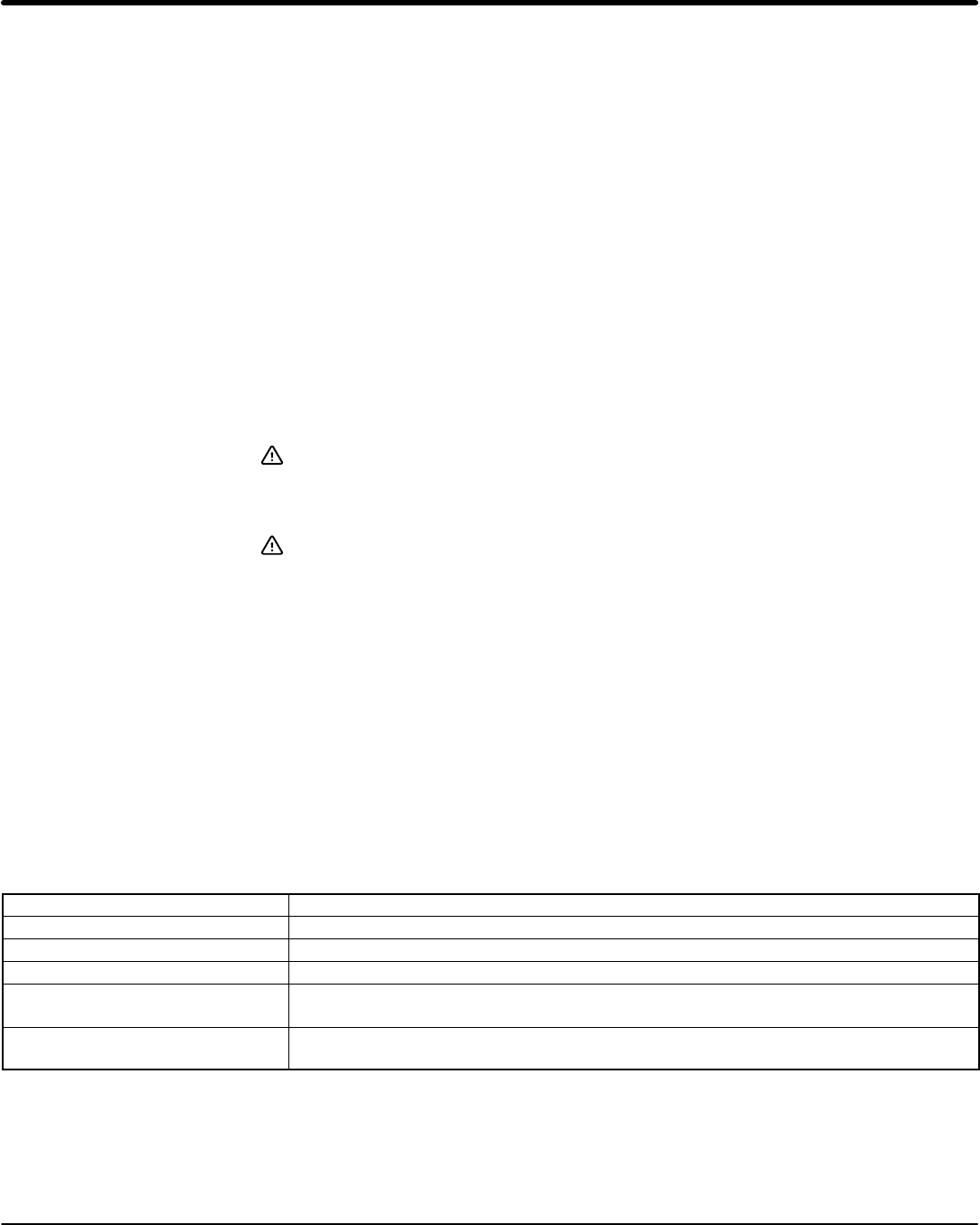

If the motor Remedy

Starts abruptly (jerks) Decrease TU by turning it CCW.

Starts too slowly Increase CL by turning it CW. Then decrease ramp time RU by turning it CW.

Starts too quickly Decrease CL by turning it CCW. Then increase ramp time RU by turning it CCW.

Is connected to a high inertial

load or a high slip motor is used

It may be necessary to increase S1 setting to allow more motor current for faster

starting.

Is not starting properly Refer to detailed starting instructions for your application for more information on

starting adjustments. Also, refer to start-up troubleshooting.