07 Wheels and tyres

156

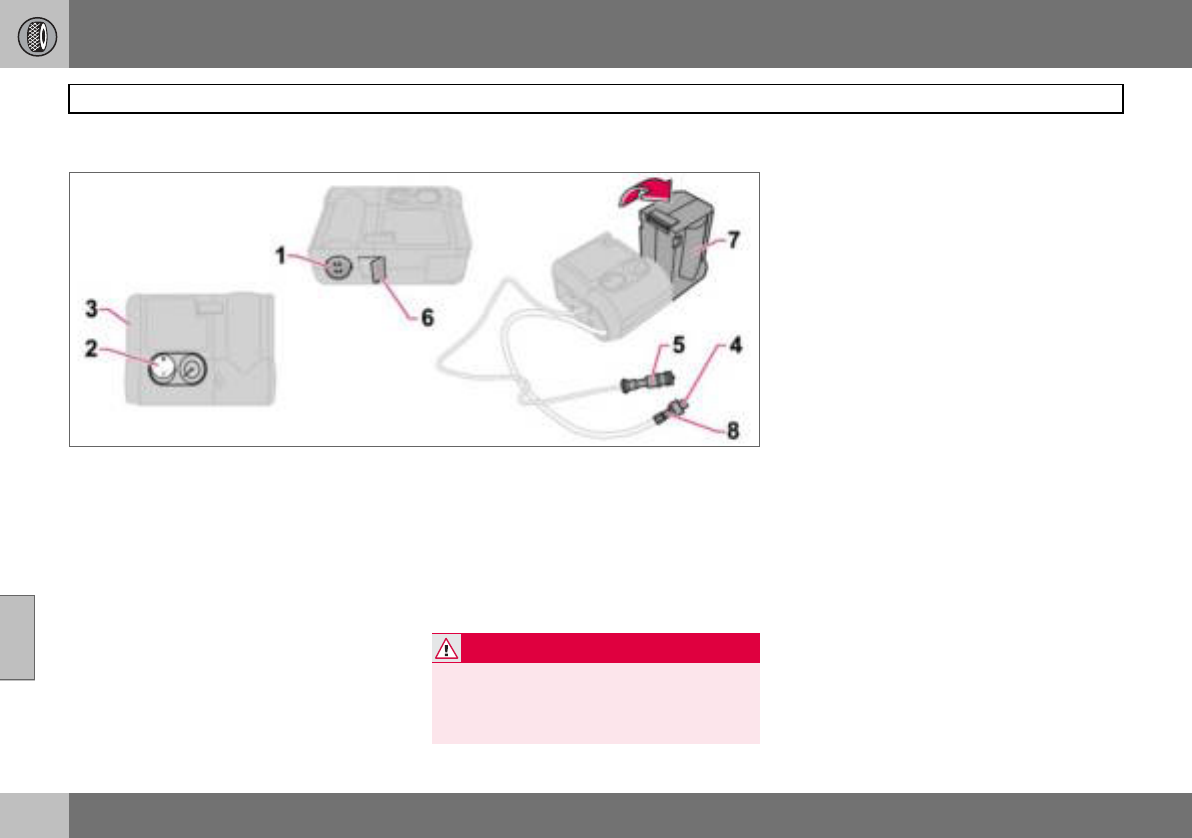

Emergency puncture repair

07

Sealing punctured tyres

Set up the warning triangle if emergency tyre

repairs must be carried out in an area where

there is other traffic.

– Remove the decal (1) regarding the high-

est permitted speed from the emergency

puncture repair kit and stick it on the

steering wheel where it can be clearly

seen by the driver.

– Ensure that the orange switch (2) is in

position 0 and take out the lead (5) and air

hose (4) from the side compartment (3).

– Screw the air hose’s valve connection to

the bottom of the thread on the tyre’s air

valve.

– Connect the lead (5) to the car’s 12 V

socket.

– Release the safety catch (6) and turn the

orange-coloured part (7) 90 degrees to the

vertical position, until a click is heard.

– Start the engine. The car must be in a well-

ventilated place.

– Start the compressor by flicking the

switch (2) to position I. There will be a

temporary pressure increase of max. 4 bar

while the sealing fluid is pumped in. After

approx. one minute, the pressure will drop

and the gauge will indicate the correct tyre

pressure.

– Pump the tyre to a pressure of between

1.8 bar and 3.5 bar. If the pressure does

not reach 1.8 bar after ten minutes of

pumping, the compressor must be turned

off so it does not overheat.

WARNING

Inhaling car exhaust fumes can result in

danger to life. Never leave the engine run-

ning in sealed areas or areas that lack suffi-

cient ventilation.