32

MITSUBISHI ELECTRIC

FR-F 740 EC

Application Examples

Ventilation systems of modern painting

plants often have high-powered motors.

This makes them an ideal application for

frequency inverters, which can replace the

contactors and “soft starter” systems with

bypass circuits that are often used in these

installations.

The higher initial investment involved in

installing frequency inverters can pay for

itself in a very short time because of the

many benefits of this solution.

Benefits

Ȝ

Reduction of switch-on and start-up

currents, also compared to soft starter

systems, thus reducing peak load

power costs.

Ȝ

Gentle flying starts for fans that are al

-

ready rotating in duct drafts, thus in

-

creasing general system service life.

Ȝ

Motor speed reduction for lower

throughput at low demand times with

-

out dampers for significant power sav

-

ings.

Ȝ

No need for bypass contactors.

Ȝ

Motor pre-heating is possible.

Ȝ

With properly-dimensioned drive sys-

tems and brake modules you can also

stop the fans quickly, for example when

fir extinguishing gas needs to be used.

Specifications

Ȝ

Drive system with 4-pole motor, 132 kW

Ȝ

Frequency inverter: FR-F 740-03250 EC

Ȝ

Acceleration/braking times: 360 s

Ȝ

S-ramp programming

Ȝ

Flying start function

Ȝ

Optimum Excitation Control function

Ȝ

Regeneration avoidance function

Ȝ

Control via analog signal (0-10 V)

Ȝ

Output frequency range 22-50 Hz

Ȝ

Average power consumption of conven

-

tional system per 24 h: 2,890 kWh

Ȝ

Average power consumption of

frequency inverter system per 24 h:

2,610 kWh

APPLICATIONS

Ventilation system

300

100

25

0

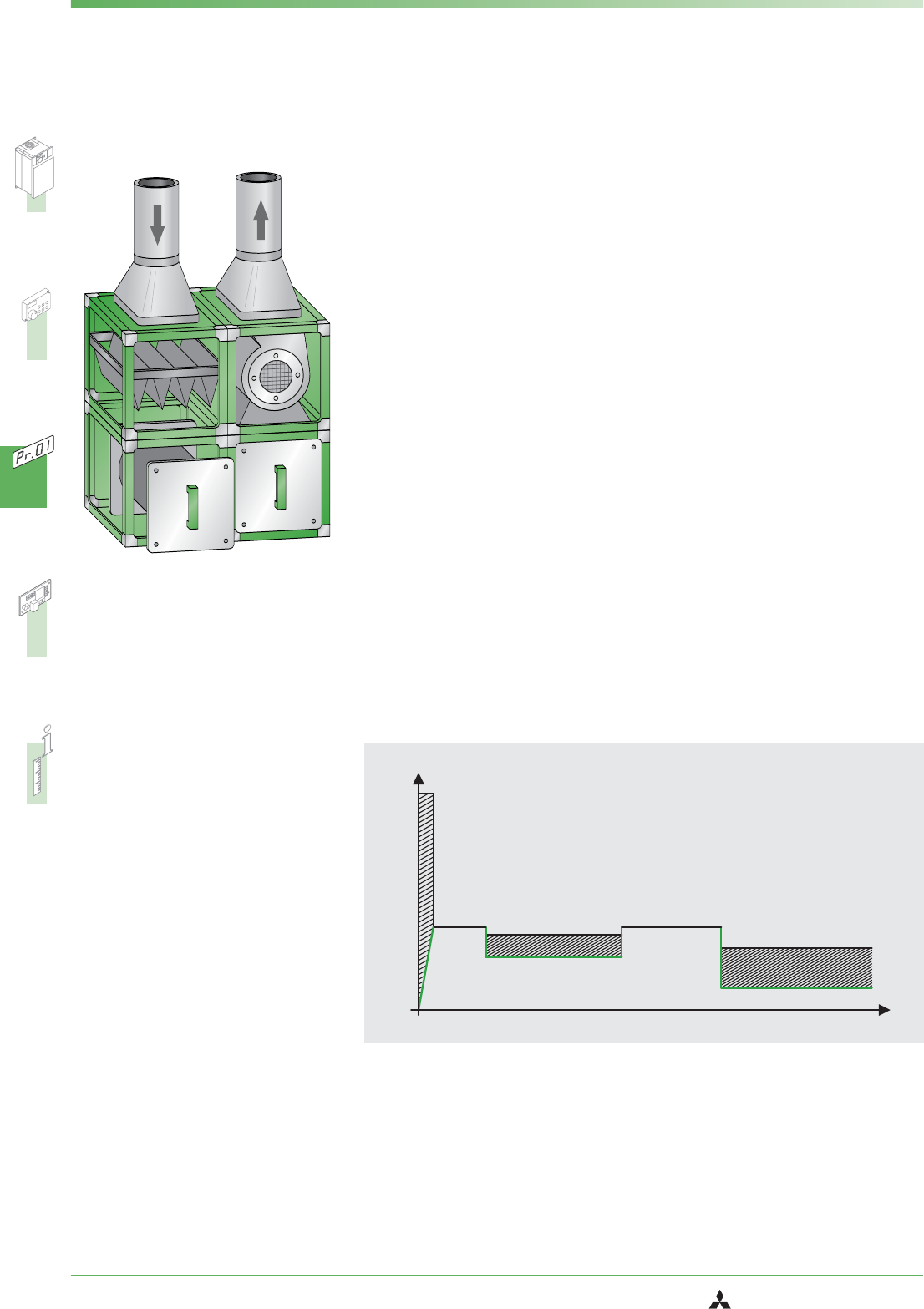

Comparison of the per-day power

consumption of a conventional pain

-

ting plant ventilation system (black

line) and a speed-controlled system

(green line).

Time [h]

Power required [%]

Start

Low load

(night mode)

1

st

load peak

Normal

throughput

2

nd

load peak