11.6

Section 11

Reassembly

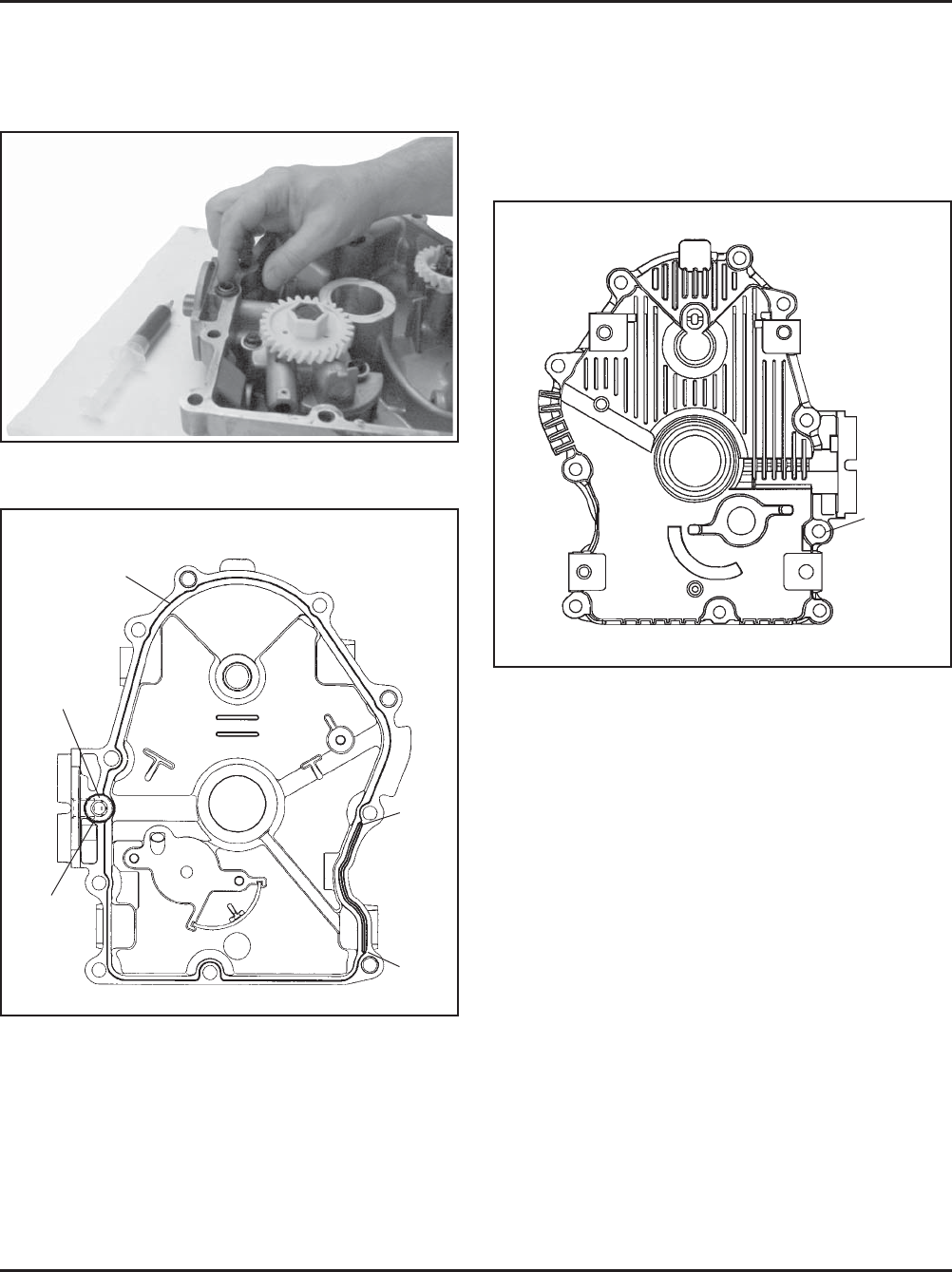

3. Install the O-Ring in groove as shown. See Figure

11-14. Apply a 1.5 mm (1/16 in.) bead of sealant

to the sealing surface of the oil pan. See Figure

11-15 for the sealant pattern.

6. Install the ten hex. flange screws securing the oil

pan to the crankcase. Torque fasteners in the

proper sequence to 24.4 N·m (216 in. lb.). See

Figure 11-16 for the proper torque sequence. On

some engines one of the ten mounting screws is

plated. The plated screw should be installed in the

#6 hole shown in Figure 11-16.

Figure 11-16. Oil Pan Torque Sequence.

Install Cylinder Studs

NOTE: Do not reinstall or attempt to reuse any

cylinder studs that have been removed.

Discard any stud(s) removed. If any of the

cylinder studs were removed from the

crankcase, install new studs at this time

as follows:

NOTE: Two different studs were used in production

and cannot be interchanged or damage to

the threads in the crankcase casting will

occur. Use only the correct replacement

stud(s). Refer to the parts manual for specific

part number when ordering.

1. Identify the longer threaded end of new stud.

See Figure 11-17. If Dri-Loc Loctite

®

is not

visible, apply Loctite

®

No. 272 to 5-6 threads

approximately 7 threads from the bottom. See

Figure 11-17.

5

3

1

2

4

6

7

8

9

10

Plated

Screw

Location

Figure 11-14. Installing O-Ring in Groove

of Oil Pan.

Figure 11-15. Oil Pan Sealant Pattern.

4. Make sure end of governor cross shaft is lying

against the bottom of cylinder 2 inside the

crankcase. See Figure 11-9.

5. Install oil pan to crankcase. Carefully seat the

camshaft with shim and crankshaft into their

mating bearings. Rotate the crankshaft to help

engage oil pump and governor gear meshes.

Point

‘‘B’’

Point

‘‘A’’

Fill Groove

Between

Points ‘‘A’’

and ‘‘B’’ with

RTV.

Apply 1.5 mm (1/16 in.)

bead of Sealant

RTV Must

Be All

Around

O-Ring

Groove

O-Ring