CJ2A Operation and Care

Manual -- Lubrication Chart

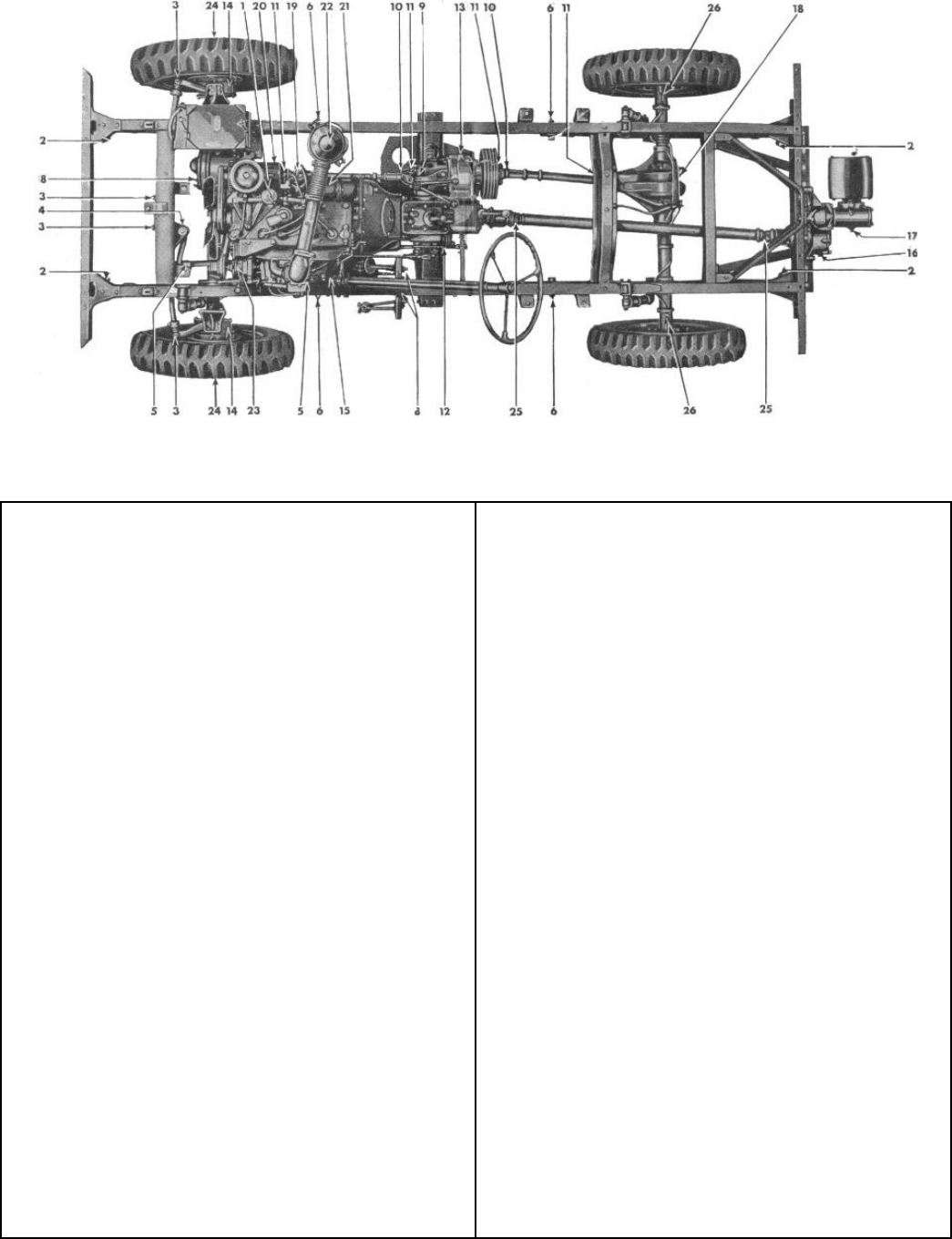

FIG. 17 -- CHASSIS, SHOWING PARTS REQUIRING LUBRICATION

Chassis Bearings, Nos. 2, 3, 4, 5, 6, 7, 8, 9, 10, 11

Clean and lubricate each 1000 of road service. Make certain each

bearing surface is properly lubricated and oil all clevis pins, yokes,

hood hooks and the upper end of the hand brake conduit. Lubricate

these parts DAILY when using the vehicle for field work as the new

lubricant will force the old from the bearings and the grit and dirt

which may have accumulated. Use No. 0 chassis lubricant for winter

and No. 1 in summer.

Engine Crankcase, No. 1

Drain engine oil when hot and refill with fresh oil each 2000 miles of

road service. For power take-off and field operation change the oil at

each 50 hours. Watch the condition of the oil closely and should it be

contaminated due to conditions of operation, change it immediately.

When changing oil, always drain the oil filter to prevent the dirty oil

in the filter from mixing with the new. Change filter unit at each

8000 miles of highway travel and each 200 hours of industrial or

field work.

Transmission and Transfer Case, No. 12, 13

Check the level in the housings each 1000 miles. Change oil at each

6000 miles of road service or 300 hours of field work. Note that the

requirements of these housings are small for economy and it is

important that the oil level be checked regularly and changed at the

time specified when the vehicle is used in heavy duty service.

Front and Rear Differentials, No. 18

Check the level at each 1000 miles and change the oil each 6000

miles of road service and 300 hours of field work. Use extreme

pressure (hypoid type) lubricant.

Front Axle King Pin Bearings and Universal Joints, No. 14

Check oil level each 1000 miles. Change the lubricant at each 6000

miles of road service and 300 hours of field service.

Steering Gear, No. 15

Check lubricant level each 1000 miles. When level is low use a hand

gun to fill the housing slowly. Avoid the use of cup grease, graphite,

white lead or heavy solidified oil.

Power Take-Off and Belt Pulley Housings, Nos. 16, 17

Check the lubricant level each time the vehicle is lubricated. Should

the units be used frequently change the lubricant each 3000 hours.

Ignition Distributor, No. 19

Lubricate each 1000 miles or equivalent in field service. Place

several drops of engine oil in the oiler at the side of housing; also

place a drop of light oil on the wick in shaft under the rotor and

sparingly apply soft grease on the breaker arm cam and a drop of oil

on the breaker arm pivot.

Generator and Starting Motor, Nos. 20, 21

Place three to five drops of oil in the oilers each 1000 miles. Do not

overlubricate.

Governor, No. 23

At each lubrication check the level in the housing. note that three

plugs are provided; drain plug, level plug and filler plug. Fill the

housing to the filler plug level with the same grade oil used in the

engine. Avoid overfilling.

Air Cleaner, No. 22

For normal operation clean the air cleaner and replace the oil each

2000 miles using the same grade used in the engine. Clean this unit

and change oil in accordance with conditions of operation -- twice

daily when the vehicle is used in extremely dusty field service.

Power Take-Off Universal Joints, No. 25

For average service the original factory lubrication will last the life

of the vehicle. If the power take-off is used often for continuous

operation, disassemble and repack once each year.

Front Wheel Bearings, No. 24

Remove the front wheel bearings and clean them thoroughly each

6000 miles of road service or 300 hours of industrial service after

which repack them with wheel bearing lubricant.

Rear Wheel Bearings, No. 26

Lubricate the rear wheel bearings sparingly with a compressor. See

WHEEL BEARINGS.

NOTE -- The water pump and clutch release bearings are

prelubricated and the lubricant lasts for the life of the bearings. Some

of the speedometers supplied are equipped with a wick type oiler

located on the drive shaft boss directly above the tube a d shaft

connection to the speedometer head. Lubricate this oiler with a few

drops of light oil twice each year.

CAUTION -- Do not use mineral oil on the shock absorber rubber

mounting connections.