ENGINE MOUNTINGS

The rubber engine mountings, which are attached to the frame side rail brackets and

to the support plate, prevent fore-and-aft motion of the engine, yet allow free

sidewise and vertical oscillation which neutralizes vibration at the source. Keep the

mountings tight. A loose engine may cause vibration, clutch chatter or high fuel level

in the carburetor.

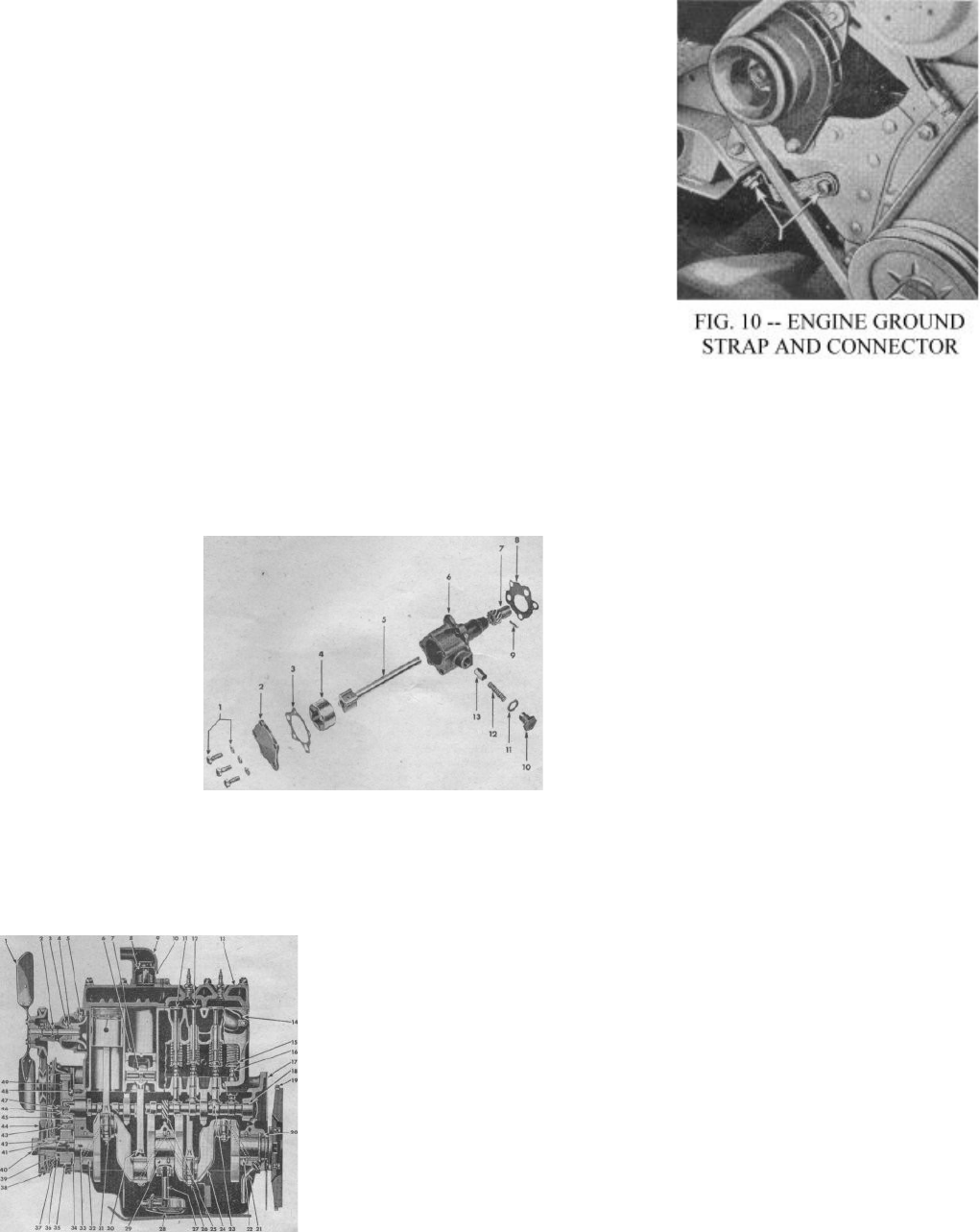

The rubber surface of the mountings partially insulates the engine from the frame. To

assure a positive electrical connection between the engine and the frame, a ground

strap is provided at the right front engine support under the generator. See Fig. 10.

The two attaching screws must be kept tight and the connections clean. A loose or

poor connection may result in hard engine starting, low charging rate of the

generator or sluggish operation of the starting motor.

OIL PUMP ASSEMBLY

The oil pump assembly is provided with a pressure relief valve which controls the maximum oil pressure at all speeds.

The standard controlled pressure is 35 lps. at 30 mph. and 10 lbs. at the idle speed of 600 rpm. as registered by the dash gauge.

Pressure may be adjusted by installing or removing shims between the relief plunger spring and the spring retainer. Add shims

to increase the pressure or remove to decrease.

1. Cover Screw

2. Cover

3. Cover Gasket

4. Outer Rotor

5. Shaft and Rotor

6. Body

7. Driven Gear

8. Gasket

9. Gear Retaining Pin

10. Relief Valve Retainer

11. Relief Valve Retainer

Gasket

12. Relief Valve Spring

13. Relief Valve Plunger

The oil pump drive shaft drives both the pump and

the distributor assembly. See Fig. 2. Should it be

necessary to remove the oil pump assembly, first

remove the distributor cap and carefully note the

position of the rotor to allow reinstallation without

disturbing the ignition timing. When the pump is

installed, use care that the driving key on the end of

the distributor shaft is correctly meshed with the slot

on the end of the pump shaft. To make the

installation without disturbing the ignition timing, the

pump gear must be correctly meshed with the

camshaft gear to allow mesh of the distributor driving

key and slot with the distributor rotor in the original

position. Should it be necessary to reset the ignition

timing, refer to the previous page.

1. Fan Assembly

2. Water Pump Bearing and Shaft Assembly

3. Water Pump Seal Washer

4. Water Pump Seal Assembly

5. Water Pump Impeller

6. Piston

7. Wrist Pin

8. Thermostat Assembly

9. Water Outlet Elbow

10. Thermostat Retainer

11. Exhaust Valve

12. Intake Valve

13. Cylinder Head

14. Exhaust Manifold Assembly

15. Valve Spring

16. Valve Tappet Self-Locking Adjusting Screw

17. Engine Plate - Rear

18. Camshaft

19. Flywheel Ring Gear

20. Crankshaft Packing - Rear End

21. Crankshaft Bearing Rear Drain Pipe

22. Crankshaft Bearing Rear - Lower

23. Valve Tappet

24. Crankshaft

25. Oil Pump and Distributor Drive Gear.

26. Connecting Rod Cap Bolt

27. Oil Float Support

28. Oil Float Assembly

29. Crankshaft Bearing Centre - Lower

30. Connecting Rod Assembly - No. 2

31. Connecting Rod Bolt Nut Lock

32. Crankshaft Bearing - Lower Front

33. Crankshaft Oil Passages

34. Crankshaft Thrust Washer

35. Crankshaft Gear

36. Crankshaft Gear Spacer

37. Timing Gear Cover Assembly

38. Fan and Generator Drive Belt

39. Crankshaft Oil Seal

40. Starting Crank Nut Assembly

41. Crankshaft Carrier Key

42. Fan and Governor Drive Pulley Key

43. Timing Gear Oil Jet

44. Fan, Generator and Governor Drive Pulley

45. Camshaft Thrust Plate

46. Camshaft Gear Retaining Washer

47. Camshaft Gear Retaining Screw

48. Camshaft Gear Thrust Plate Retaining Screw

49. Camshaft Gear