Also select the correct upper side rail (a rod approximately 30” long with one end curved) which will assemble with the curved

end next to the windshield with the curve extending up and out and with the welded eye extending in.

After selecting the correct parts install the clamp bracket, with the stud extending in and place the eye in the curved end of the

side rail over the stud on the inside of the clamp bracket. Tighten the stud nut with the clamp bracket positioned so the side rail

is level with the top of the windshield. Attach the rear end of the side rail to the eye on the top bow with the bolt lockwasher

and nut provided. Make the same assembly on the opposite side.

Next install the attaching side curtains which carry the door latches. The right and left sides may be easily selected as the lap of

the seam goes inside. Place the upper end of the rod in the curtain through the eye mounted on the side rail and attach the lower

end at the holes provided in the body. Place the bolt heads on top.

Place the top deck covering over the top bow and attach the front end on the fasteners across the top of the windshield. Fasten

the covering to the top bow with the two outer flaps. Hook one end of the centre supporting brace in the eye at the top centre of

the windshield frame and make the covering taut by hooking the rear end in the top bow eye. Fasten the centre top attaching

flap over the rear end of the supporting brace.

Snap the door jambs, which are part of the top covering, around the side rails at the top of the door openings.

Install the doors and attach the front sides to the body and windshield supports. It is necessary to open the windshield to button

the upper fasteners.

Attach the rear curtain, pulling the holding straps at the bottom taut only.

REAR ENCLOSURE

Assemble the centre section of the rear top bow between the side sections and install the assembly in the body sockets. Place

the top over the bow and fasten the front end to the rear of the front top.

The side curtains are made for the right and left sides, but when correctly installed the straps are at the bottom and on the

inside and the cutout corners are placed at the upper rear. Install both the side and rear curtains. Attach and pull down the

straps taut only.

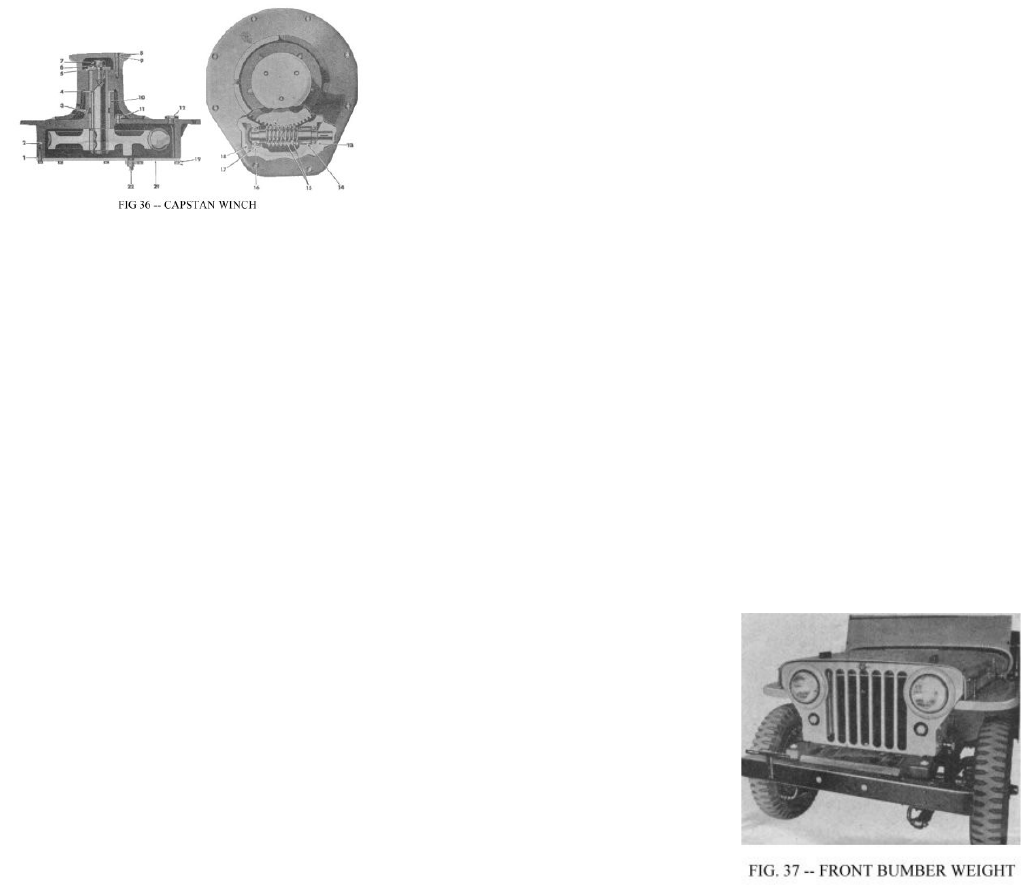

1. Cover Plate Gasket

2. Gear Box

3. Capstan Shaft Grease Fitting

4. Capstan Shaft Thrust Washer

5. Capstan Shaft Retaining Screw

6. Capstan Shaft Screw Lockwasher

7. Capstan Shaft Screw

8. Cover Screw

9. Cover Screw Lockwasher

10. Capstan Shaft Bushing (Upper)

11. Capstan Shaft Bushing (Lower)

12. Filler Plug

13. Worm Shaft Oil Seal

14. Worm Shaft Needle Bearing

15. Worm and Gear Set

16. Worm Shaft Ball Bearing

17. Bearing Retainer Cap Gasket

18. Bearing Retainer Cap

19. Gear Box Cover Plate Screw

20. Gear Box Cover Pate Screw Lockwasher

21. Cover Plate

22. Drain Plug

CAPSTAN WINCH

The capstan winch is designed for 5000 lb. Pull, using either ¾” or 1” manila rope. The worm gears have a ratio of 75 to 1

which provides a rope speed of 19 feet per minute with an engine speed of 1200 rpm. A shift lever is mounted on the assembly

for engagement control.

Engage the drive with the engine idling only and without load: limit the engine speed to 1200 rpm.

Lubrication is important because the parts must withstand high pressures when operating at maximum pull. Filler and drain

plugs are provided in the gear housing with an oil level stick on the filler plug. The oil capacity is one quart of SAE 90 gear oil

in Summer and SAE 80 in Winter. Change the oil twice each year – in Fall and Spring.

Hydraulic fitting No. 3, Fig. 36, is provided to lubricate the capstan spindle, the position of which is indicated by the arrow

cast on the gear box. To lubricate the spindle, align the opening in the capstan with arrow. Use chassis lubricant to lubricate the

spindle, also lubricate the rope roller at each end and the shift rail and the drive shaft bushing in the winch drive support

bracket mounted on the front of the engine. Use an oil can to lubricate the winch drive universal joints.

A cotter pin is used to pin the winch drive shaft to the universal joint at the engine end and acts as a shear pin to prevent

overloading. Should this pin shear off, be sure to replace it with a cotter pin of the same size. Do not replace it with a solid pin

or drill the hole oversize for a larger pin.

FRONT BUMPER WEIGHT

The best performance of a four-wheel drive vehicle is achieved when the load is equally

distributed for traction on the front and rear wheels. This equal distribution is disturbed

when the vehicle is used for draw bar work because the load on the rear wheels is

increased and that on the front wheels decreased. The addition of a 265-pound front

bumper weight equalizes this load.

When the load is equalized the front and rear axles do approximately the same work

which results in an equal and prolonged life of these parts and more satisfactory vehicle

performance.

The bumper weight Fig. 37 is held in place by four bolts and is provided with hand holes

for lifting. Do not add sand bags or other weights in the vehicle. When driving over

rough terrain, with the bumper weight in place, the driver should exercise due care.