CJ2A Operation and Care

Manual -- Proper Maintenance

NEVER RUN ENGINE IN CLOSED GARAGE

Due to the presence of carbon monoxide (a poisonous gas in the exhaust of the engine) never rub the engine for

any length of time while the vehicle is in a small closed garage. Opening the doors and windows will lessen the

danger considerably, but it is safest if adjustments are being made that require the operation of the engine, to

run the vehicle out-of-doors.

INSPECTION.

The old adage "An ounce of prevention is worth a pound of cure" was never more true than when applied to any motor vehicle.

The importance of regular systematic inspection cannot be over-emphasized. Small and seemingly unimportant faults, if

neglected, may grow into expensive major repairs. Regular inspections and prompt correction of small faults will go far toward

holding down maintenance expense, eliminating delays in productive operations and upholding the high standard of reliability

and performance built into your "Jeep" at the factory.

ENGINE TUNE-UP.

For best performance and dependability the engine should have a periodic tune-up twice yearly, preferably in the Spring and

Fall.

• Remove the spark plugs, clean them thoroughly and space the electrodes to .030" (0.76 mm.) gap.

• Clean and tighten the battery cable terminals, the battery ground connection and the ground strap on the right side of

the engine at the front engine support (See Fig. 10).

• Remove the distributor cap and inspect the contact points. Adjust the points to .020" (0.51 mm.) gap. See Fig.7 No.5.

• Check the ignition timing.

• Check the valve tappet clearance. Adjust to .014" (0.356 mm.) clearance with engine hot or cold.

• Clean the fuel pump filter screen and check fuel line connections.

• Remove ventilator valve Fig. 12 and clean.

• Start the engine and allow it to run until thoroughly warm then set the carburetor idle screw so the engine will idle at

600 rpm. (vehicle speed of approximately 6 mph).

• Adjust the carburetor low speed idle screw so that the engine will idle smoothly.

NOTE: Should the engine fail to perform satisfactorily and the trouble is definitely traced to the carburetor, consult your

Willys-Overland Dealer. Carburetor service is specialized and should not be undertaken unless the unit is thoroughly

understood.

VALVE AND IGNITION TIMING

Inlet opens 9 degrees before top centre

Inlet closes 50 degrees after bottom centre

Exhaust opens 47 degrees before bottom centre

Exhaust closes 12 degrees after top centre

Spark Setting

Spark set top centre with automatic spark controls at rest, when using low octane fuel.

Firing Order

Tappet setting for valve timing

Number of flywheel teeth

Piston Measurements from Top Centre

039" (9.91 mm.)

3.772" (95.81 mm.)

3.799" (96.49 mm.)

.054" (0.14 mm.)

"IGN" 5º BTC

1-3-4-2

.020" (0.51 mm.)

97

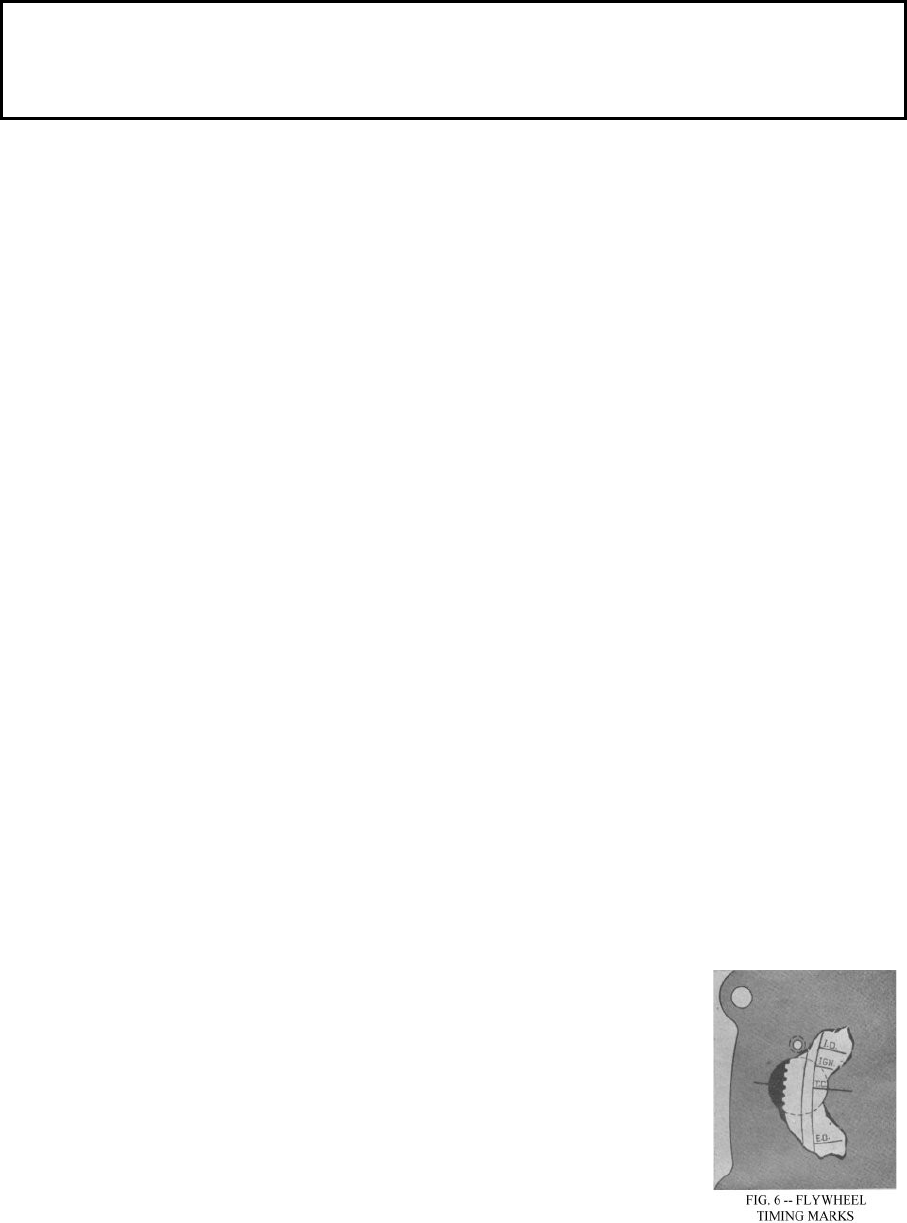

CHECKING VALVE TIMING

To check the valve timing, adjust the inlet valve tappet No. 1 cylinder to .020" (0.51

mm.). Use care in making this adjustment that the measurement is accurate with

feeler gauges and that the tappet is resting against the lowest surface of the camshaft

cam. Rotate the crankshaft clockwise until piston in No. 1 cylinder is ready for the

intake stroke. (Mark "I-O" -- intake open -- on the flywheel is in the centre of the

engine.) With the crankshaft in this position, valve timing is correct if No. 1 intake

valve tappet is jut tight against the end of the valve stem. After checking, adjust all

of the tappets .014" (0.356 mm.).

Should the timing be incorrect it is advisable to consult your Willys-Overland Dealer

IGNITION TIMING