CJ2A Operation and Care

Manual -- Proper Maintenance

(part 6 -- Brakes)

BRAKES

The foot or service brakes are hydraulically actuated in all four wheels. The brakes are of the two-shoe, double anchor type and

have chrome-nickle alloy iron drums. The hand brake is mechanically operated through a cable and conduit to an internal

expanding type brake mounted on the propeller shaft at the rear of the transfer case.

FOOT BRAKES

In operation, pressure is applied to the hydraulic liquid in the master cylinder through the foot pedal, forcing the liquid through

the lines and into the wheel cylinders. The pressure forces the pistons in each wheel outward, expanding the brake shoes

against the drums. As the pedal is further depressed, higher pressure is built up within the hydraulic system, causing the brake

shoes to exert greater force against the brake drums. As the brake pedal is released the brake shoe return springs pull the shoes

together forcing the fluid out of the cylinders and back into the lines toward the master cylinder.

The master cylinder may be reached by removing the five screws in the inspection cover on the toe board below the steering

column. Keep the master cylinder reservoir full at all times. Use only genuine hydraulic brake fluid. Check the level each 1000

miles and use care, when removing the filler cap, that no dirt enters the reservoir. The fluid capacity is approximately ¾ pts.

The hydraulic brake system must be bled whenever a fluid line is disconnected or air enters the system due to low fluid level in

the master cylinder reservoir. A leak in the system may be indicated by a “spongy” pedal. Air trapped in the system is

compressible and does not permit pressure, applied to the brake pedal, to be transmitted solidly to the brakes. Should bleeding

be required, consult your Willys-Overland Dealer.

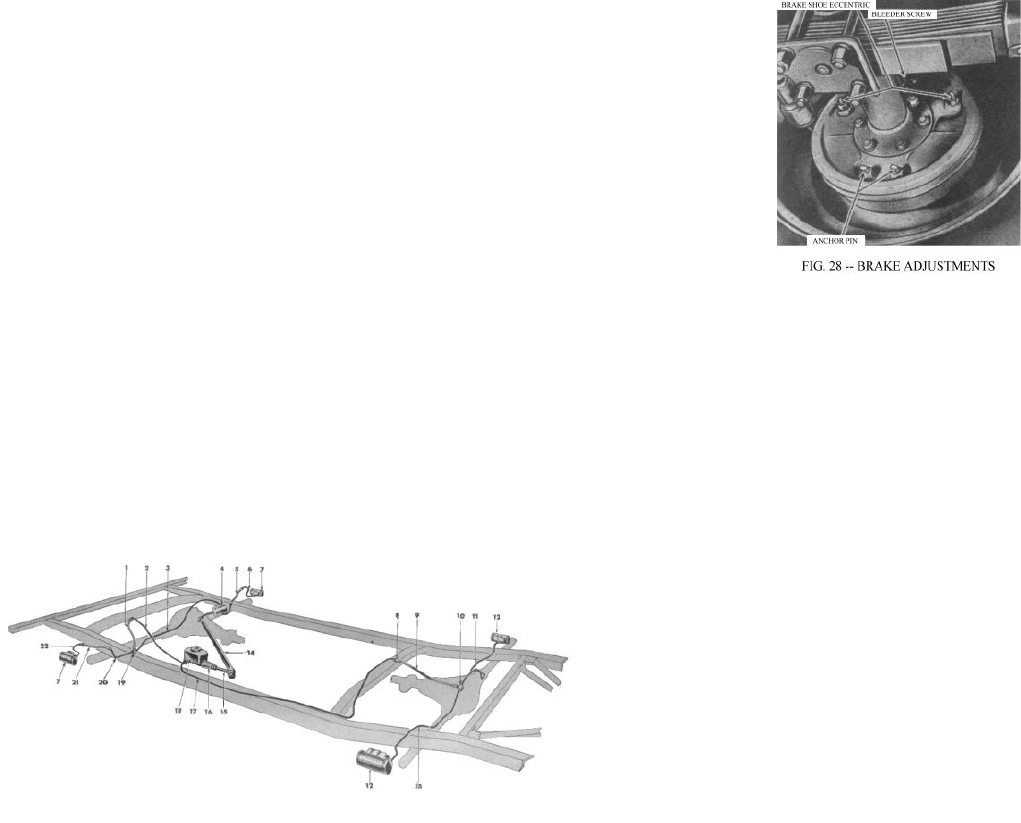

BRAKE SHOE ADJUSTMENT – MINOR

When the brake lining becomes worn the effective brake pedal travel is reduced. The effective

travel may be restored by adjusting the brake shoes.

First make sure that there is ½” pedal travel, without moving the master cylinder piston,

which is necessary to prevent the brakes from dragging due to expansion of the hydraulic

liquid.

Jack up the wheels to clear the floor. Adjustment is made by relocating the brake shoe

eccentrics Fig. 28. Loosen the lock nut for the forward brake shoe and hold the nut while

turning the eccentric toward the front of the car, with another wrench, until the shoe strikes

the drum. Turn the wheel with one hand and release the eccentric until the wheel turns freely

then hold the eccentric and tighten the lock nut. To adjust the reverse or rear shoe, repeat this

operation except turn the eccentric toward the rear of the car. Do this on all brakes and check

the fluid level in the master cylinder reservoir.

As pressure is equal in all parts of the system, the brakes are self-equalizing

HAND BRAKE

To adjust the hand brake the sequence below should be followed:

Make sure that the brake handle on the instrument panel is fully released. Give due attention to the cable and operating linkage

to see that they do not bind. Should the cable fail to slide freely into the conduit, remove and lubricate it.

Rotate the brake drum until one pair of the three sets of holes are opposite the two adjusting screw wheels in the brake. Use the

edge of the holes as a fulcrum for a suitable adjusting tool or a screw driver, rotate each notched adjusting screw by moving the

handle of the tool away from the centre of the drive shaft until the shoes are snug in the drum. Back off seven notches on each

adjusting screw wheel to secure the correct running clearance between the shoes and the drum.

Should either the foot or hand brakes require relining or other extensive work, contact your Willys-Overland Dealer.

1. Brake Hose - Front Axle to

Frame

2. Brake Tube - Master

Cylinder to Front Hose

3. Brake Tube - Tee to Front

Brake Hose, Right

4. Brake Pedal

5. Brake Hose - Front Axle

6. Brake Tube - Wheel

Cylinder to

Hose

7. Wheel Brake Cylinder -

Front

8. Brake Hose Spring Lock

Clip

9. Brake Hose Assembly

10. Rear Brake Tee

11. Brake Tube - Rear Axle

Tee to

Right Rear Axle

12. Wheel Brake Cylinder -

Rear

13. Brake Tube - Rear Axle

Tee to

Left Rear Brake

14. Brake Pedal Shaft

15. Master Cylinder Eye Bolt

16. Master Cylinder Boot

17. Brake Tube - Master

Cylinder to Rear Hose

18. Brake Master Cylinder

19. Rear Axle Tee

20. Brake Tube - Tee to Left

Front

Brake Hose

21. Brake Hose - Front Axle

22. Brake Tube - Wheel

Cylinder to Hose