www.mivec.co.nz

4G9 ENGINE (E–W) – Crankshaft, Cylinder Block, Flywheel and Drive Plate

11A-12-7

PWEE9502-A

E

Nov. 1995Mitsubishi Motors Corporation Revised

Caution

To prevent distortion that may result from temperature

rise during honing, bore cylinders, in the order of

No. 2, No. 4, No.1 and No. 3.

(5) Hone to the final finish dimension (Piston O.D. + clearance

between piston O.D. and cylinder.)

(6) Check the clearance between piston and cylinder.

Clearance between piston and cylinder:

0.02 – 0.04 mm

NOTE

When boring cylinders, finish all of four cylinders to the

same oversize. Do not bore only one cylinder to an

oversize.

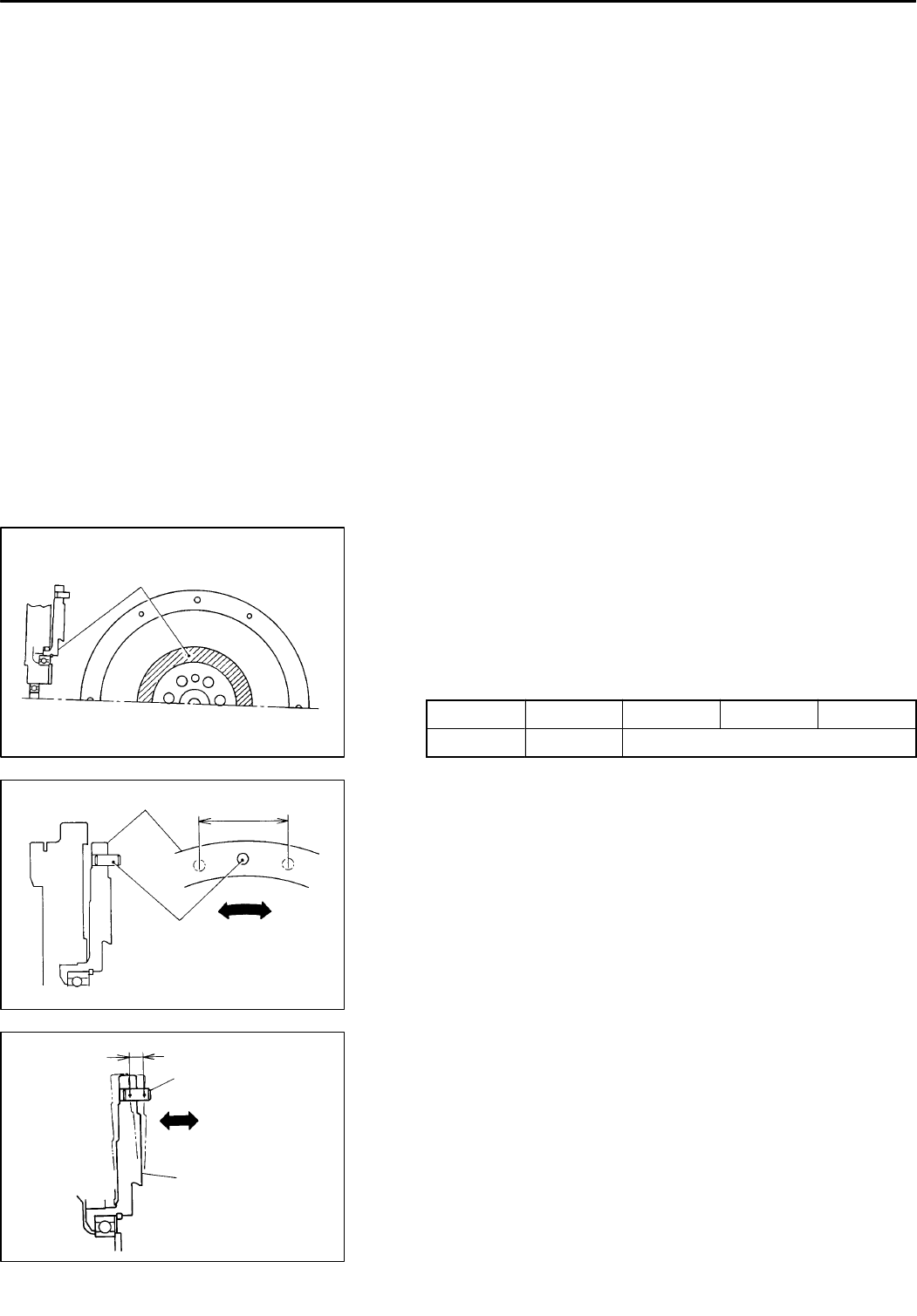

HYDRO-FLYWHEEL <DOHC–GDI for PAJERO io>

(1) Check the rear side of the flywheel for color of the hatched

area A in the illustration, and determine whether it is

serviceable or not in accordance with the criteria given

in the following table.

If judged unendurable for reuse, replace the flywheel

assembly.

Color Purple Dark blue Light blue Gray

Judgment Reusable Not reusable

(2) Measure the play in the circumferential direction using

the following procedure.

(3) Turn the flywheel clockwise and anticlockwise to measure

the distance over which the dowel pin moves freely.

Limit: 9 mm

(4) Check the friction surface for runout in the following

manner.

(5) Apply a thrust force of approx. 98 N by hand on the

flywheel to move it in the axial direction, and measure

the runout at the dowel pin position. If the limit is exceeded,

replace the flywheel assembly.

Limit: 0.75 mm

PWEE9502-I

E

Mar. 2001Mitsubishi Motors Corporation Revised

A

4ME0272

Flywheel

Dowel pin

Distance moved

4ME0273

Runout

Dowel pin

4ME0274

Flywheel