www.mivec.co.nz

4G9 ENGINE (E–W) – Crankshaft, Cylinder Block, Flywheel and Drive Plate

11A-12-4

PWEE9502-A

E

Nov. 1995Mitsubishi Motors Corporation Revised

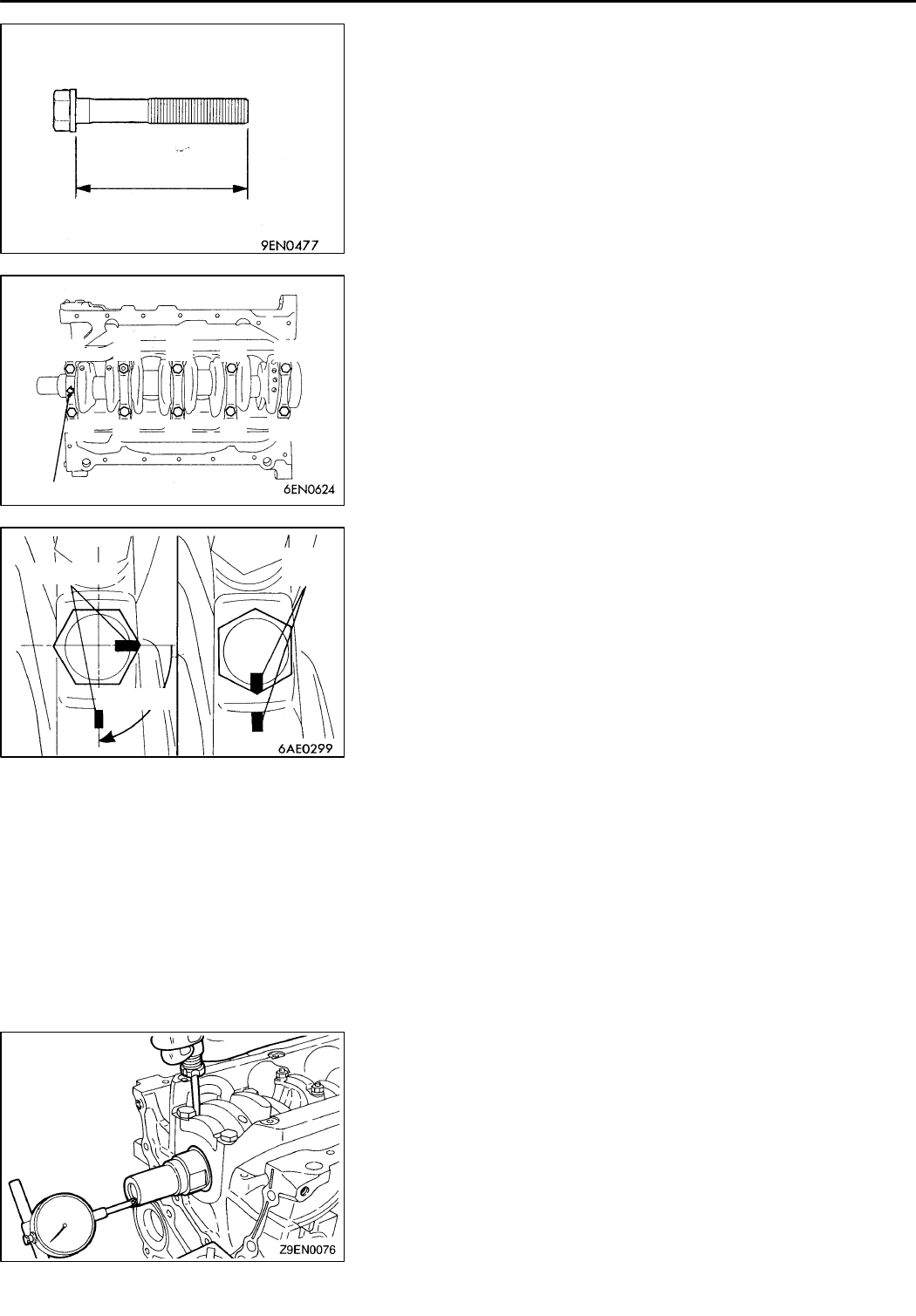

"CA BEARING CAP/BEARING CAP BOLT INSTALLATION

(1) Install the bearing caps so that their arrows are positioned

on the time belt side.

(2) When installing the bearing cap bolts, check that the

shank length of each bolt meets the limit. If the limit is

exceeded, replace the bolt.

Limit: max. 71.1 mm

(3) Apply engine oil to the threaded portion and bearing

surface of the bolt.

(4) Tighten the bearing cap bolts to 25 Nm torque in the

tightening sequence.

(5) Make a paint mark on the head of each bolt.

(6) Make a paint mark on the area around the bolt bearing

surface at location 90_ to 100_ in the direction of tightening

the bolt, as referenced from the paint mark on the bolt

head.

(7) Give a 90_ to 100_ turn to the bolts in the tightening

sequence. Make sure that the paint mark on the bolt

and that on the area around the bolt bearing surface

are in alignment.

Caution

1. If the bolt is turned less than 90_, proper fastening

performance may not be expected. When

tightening the bolt, therefore, be careful to give

a sufficient turn to it.

2. If the bolt is overtightened (exceeding 100_),

loosen the bolt completely and then retighten it

by repeating the tightening procedure from step

(1).

(8) After installing the bearing caps, make sure that the

crankshaft turns smoothly and the end play is correct.

If the end play exceeds the limit, replace crankshaft

bearings.

Standard value: 0.05 – 0.25 mm

Limit: 0.4 mm

PWEE9502-I

E

Mar. 2001Mitsubishi Motors Corporation Revised

Length of shank

(8) (4) (1)

(5) (9)

(7) (3) (2) (6) (10)

Arrow

90_ – 100_

Paint marks

Paint

marks