www.mivec.co.nz

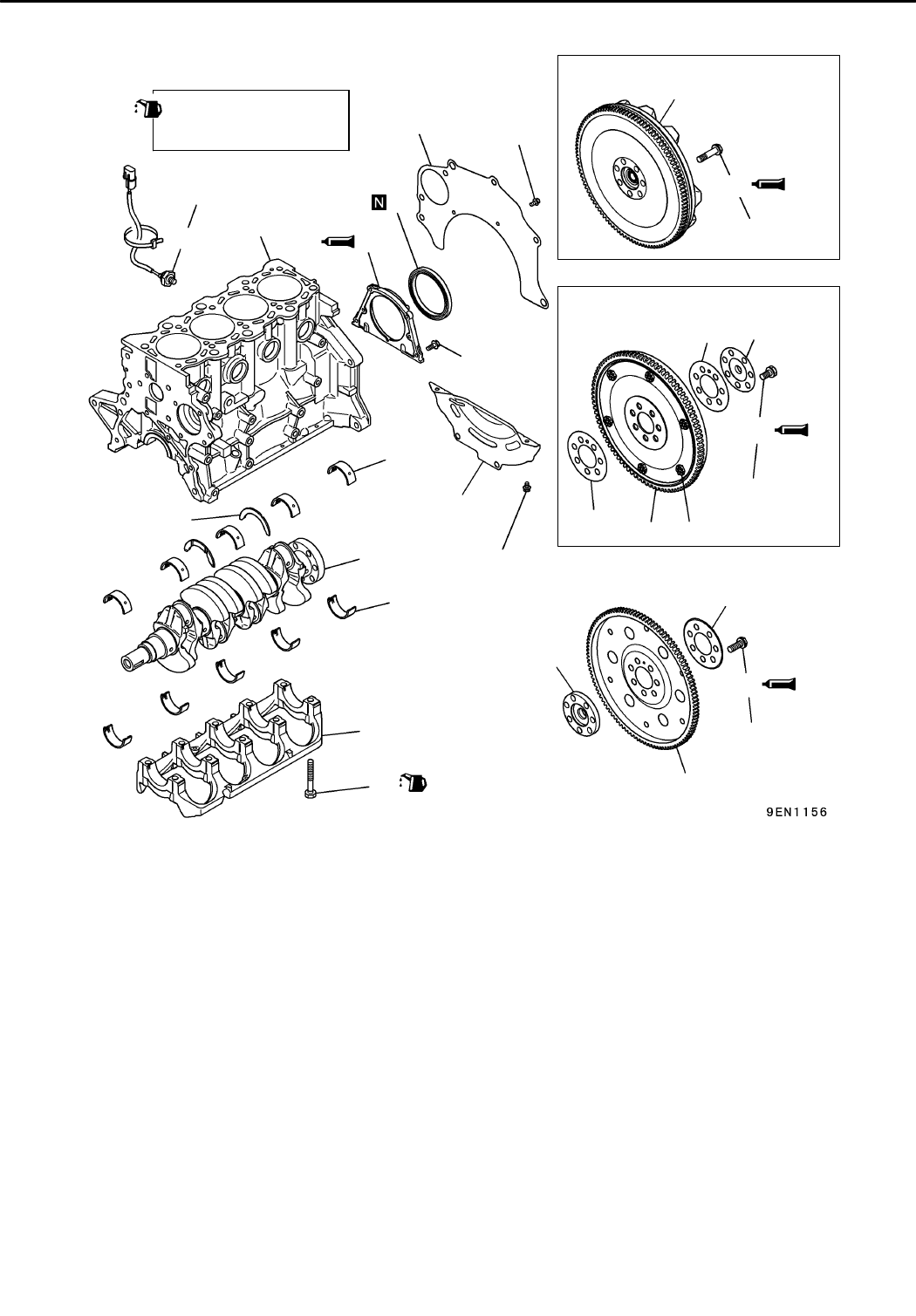

4G9 ENGINE (E–W) – Crankshaft, Cylinder Block, Flywheel and Drive Plate

11A-12-1b

REMOVAL AND INSTALLATION <PAJERO io>

11 Nm

98 Nm

11 Nm

Apply engine oil to

all moving parts

before installation.

22

23

17

15

16

3

9

5

6

12

14

23 Nm

19

21

20

13

98 Nm

1

2

8

98 Nm

10

18

7

4

A

11

<Engines with hydro flywheel>

<Engines with flexible flywheel>

Flange bolt 10 Nm

Bolt, washer assembly 9 Nm

Removal steps

"FA 1. Flywheel bolt <M/T>

2. Flywheel <M/T>

"FA 3. Flywheel bolt <M/T>

4. Plate <M/T>

5. Adapter plate <M/T>

6. Flywheel <M/T>

7. Adapter plate <M/T>

"FA 8. Drive plate bolt <A/T>

9. Adapter plate <A/T>

10. Drive plate <A/T>

11. Crankshaft adaptor <A/T>

12. Rear plate

13. Bell housing cover

<with transmission stay>

"EA 14. Rear oil seal case

"DA 15. Oil seal

"CA 16. Bearing cap bolt

"CA 17. Bearing cap

"BA 18. Crankshaft bearing, lower

19. Crankshaft

"BA 20. Thrust plate

"BA 21. Crankshaft bearing, upper

22. Knock sensor

23. Cylinder block

Caution

On the flexible wheel equipped engines, do not remove any of the bolts “A” of the flywheel shown

in the illustration.

The balance of the flexible flywheel is adjusted in an assembled condition. Removing the bolt,

therefore, can cause the flexible flywheel to be out of balance, giving damage to the flywheel.

PWEE9502-K

E

Jun. 2002Mitsubishi Motors Corporation Revised