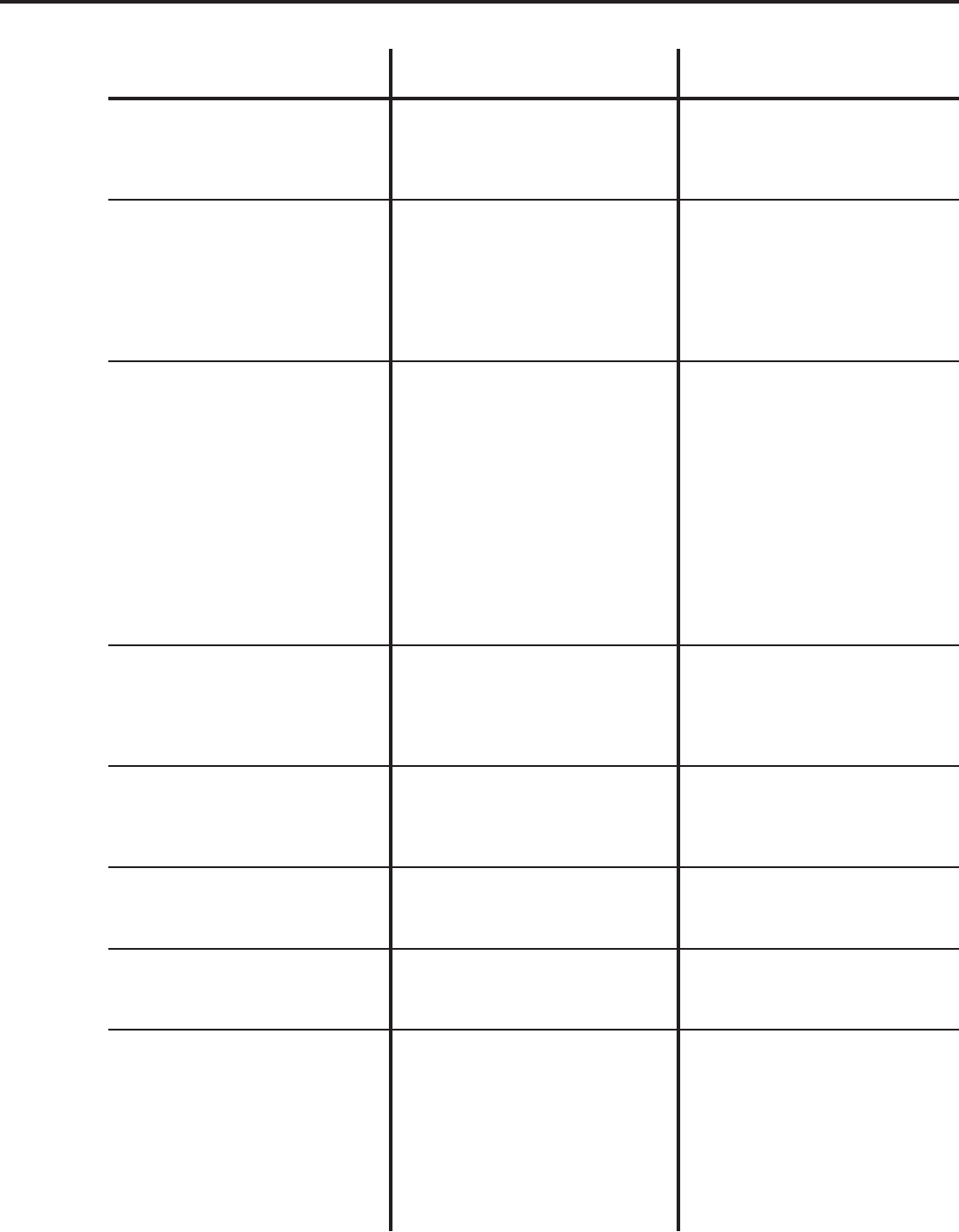

37

CONDITIONS

POSSIBLE CAUSES

CORRECTIONS

5. Control drive runs in the wrong

direction with input signal

applied.

6. Control drive does not follow

input signal until maximum or

minimum signal is reached,

then drives uncontrollably to

limit.

7. Control drive motor oscillates in

AUTO mode.

8. Control drive motor erratic

or runs in wrong direction in

automatic or manual operation.

9. Control drive will not run in

either direction or one direction

in automatic or manual

operation.

10. Control drive erratic while

closing valve and runs normally

while opening in AUTO.

11. Control drive runs

uncontrollably to some position,

then oscillates.

12. Control drive does not stop at

normal or desired limit of shaft

travel.

a. Input signal reversed.

b. Drive configured for wrong

direction of travel.

a. Yellow and black wires on

RET and EXT limit switches

reversed or potentiometer end

connections reversed.

b. CPS-2 feedback out of phase

with control motor.

a. Feedback potentiometer dirty.

b. Excessive noise on input signal.

c. Physical obstruction (e.g., valve

jammed or load greatly exceeds

rating of drive).

d. ESR-4 circuit board failure.

e. Excessive wear in gear train or

bearings.

a. Control motor winding open.

b. Control motor capacitor shorted

or open.

c. Control motor resistor open.

a. Limit switch failure.

b. Handswitch failure.

a. Feedback potentiometer dirty.

Loss of feedback voltage drives

the unit in RET direction.

a. Feedback potentiometer open.

a. ESR-4 span or zero adjusted

incorrectly.

b. Limit switches adjusted

incorrectly.

c. Loss of input signal. Check LED

on ESR-4 circuit board.

d. Limit switch failure.

e. CPS-2 calibration incorrect.

a. Check polarity of input signal.

Terminal AA (+), terminal BB (-).

b. See page 25 for changing

direction of travel.

a. Change direction of travel; see

page 25. Check correct film

potentiometer connections; see

page 26.

b. Restore proper phasing of

CPS-2 feedback with control

motor. See page 27.

a. Clean or replace potentiometer.

b. Check setting of input filter. May

require lower gain setting if

oscillation remains with maximum

filter setting; see page 31.

c. Check operation with Handswitch

and remove obstruction if

present. Handswitch bypasses

ESR-4 board.

d. Replace ESR-4 circuit board.

See page 35.

e. Replace worn drive train parts.

a. Replace control motor. See

page 33.

b. Replace capacitor. See page

33.

c. Replace resistor. See page 33.

a. Replace limit switch. See page

34.

b. Replace Handswitch. See page

35.

a. Clean feedback potentiometer

with mild soap and water.

a. Replace feedback potentiometer.

a. Recalibrate ESR-4 board. See

page 30.

b. Readjust limit switches. See

page 22.

c. Restore input signal to control

drive.

d. Replace limit switch. See page

34.

e. Calibrate CPS-2; see page 27.