22

SWITCH ADJUSTMENTS

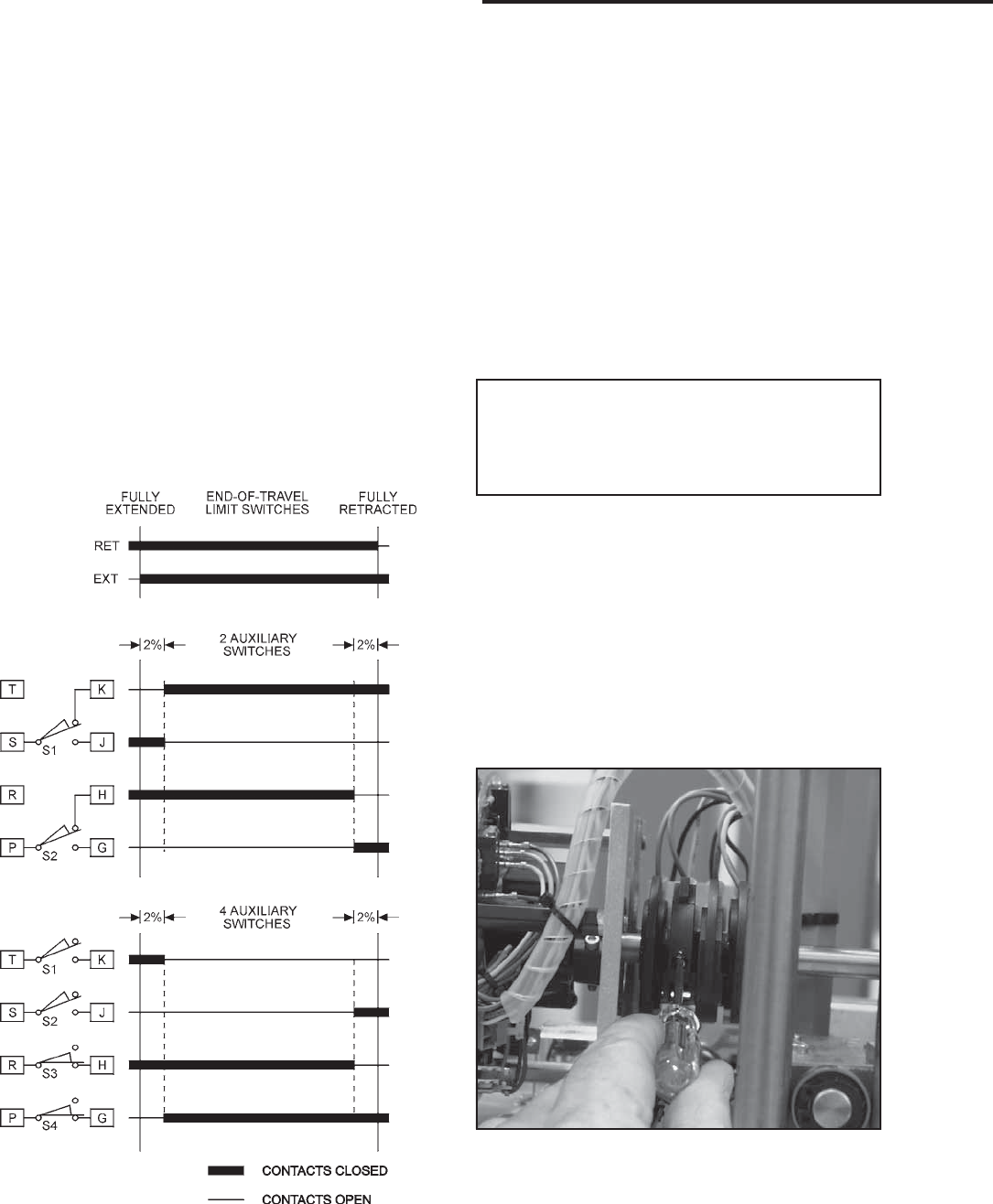

All Group 14 control drives are shipped with

end-of-travel limit switches and all auxiliary

switches factory adjusted for 100% of travel

unless otherwise specified at time of order. Limit

switches must be set inside the range of the

built-in mechanical stops to prevent stalling of the

motor.

Although the switches may be reset through

adjustment of the cam position, it is usually

advisable to change the valve travel by using the

Calibar index feature described on page 24.

Each switch should open the motor circuit

before the mechanical stop is reached. Use

the travel index on the output shaft to check the

setting. Three percent or more between the

mechanical and electrical limits is satisfactory.

To check, drive to the electrical limit using the

Handswitch, and then turn the Handwheel until

the mechanical stop is reached.

All switches are SPDT and are rated at 6 A, 120

V ac. Switches are operated by cams which are

clamped on to the control shaft. Setting a switch

involves loosening the cam, moving the output

shaft to the desired position, and positioning the

cam so that it just operates the switch at that point.

In the following procedure, the use of a continuity

meter is recommended to determine when the

switch opens or closes. If such a meter is not

available, it is possible to hear the switch click as

the contacts open and close.

CAUTION

Do not attach the meter or attempt to move the

switch cams until the drive is disconnected

from the line voltage and auxiliary switches

are disconnected from external power

sources.

Setting Travel Limit Switches

RET and EXT

This procedure should be used if the factory

end of travel switch settings must be changed in

the field. It is advisable to operate the drive fully

each direction, using the electric Handswitch

to check switch settings before attempting to

change them. Follow these instructions if they

require adjustment.

STANDARD END OF TRAVEL LIMIT

AND AUXILIARY SWITCH SETTINGS

CALIBRATION SWITCHES

FFigure 5