36

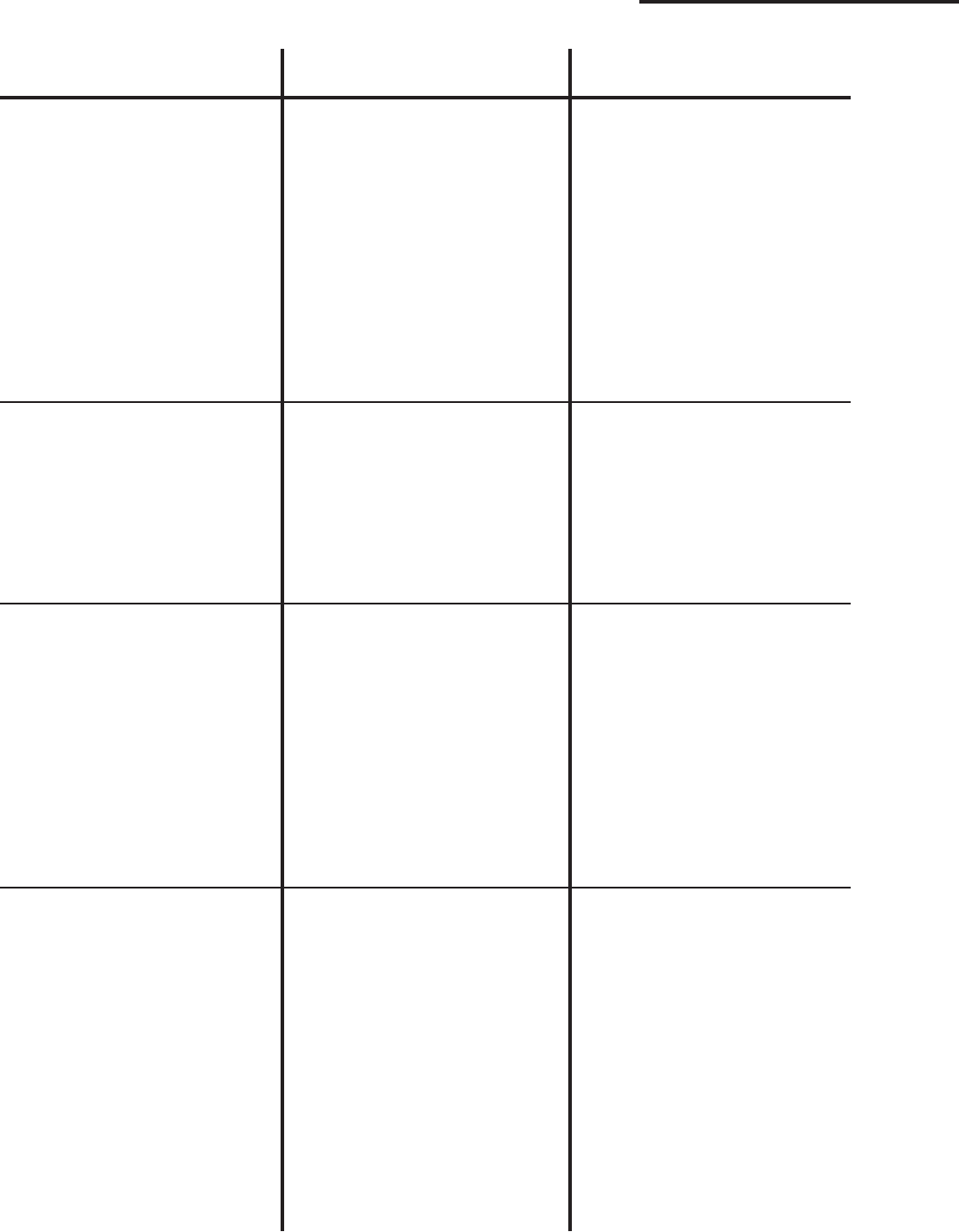

CONDITIONS

POSSIBLE CAUSES

CORRECTIONS

If your unit contains a Stall Protection Module (SPM) refer to publication 80-0017-03, page 7, “Troubleshooting”.

1. Control drive will not run in

either direction with input signal

applied to ESR-4 Board. No

lamps lit on ESR-4 board.

2. Control drive will not run in

either direction with input

signal applied to ESR-4 board.

CPS-2 LED light out and

jumper removed from monitor

board relay.

3. Control drive runs in one

direction only in AUTO, and

both directions with Handswitch

in RET and EXT.

4. Loss of ESR-4 signal lamp

lights (red LED) with input

signal applied.

a. Handswitch left in wrong

position.

b. No 120 V ac line supply.

c. Fuse F-1 open.

d. External auto / man switch in

wrong position (Position-AII).

e. ESR-4 board failure.

f. Jumpers between terminals F-N

and D-M are not connected.

a. No power.

b. Control drive positioned beyond

calibrated limits.

c. CPS-2 rotor position not set

properly.

d. CPS-2 not calibrated correctly.

e. CPS-2 failure.

a. ESR-4 zero adjustment

incorrect.

b. Handswitch failure.

c. Loss of input signal with “Drive

to Zero” or “Drive to full travel”

selected.

d. ESR-4 circuit board failure.

e. Loss of feedback signal.

a. ESR-4 zero adjustment

incorrect.

b. Input signal reversed.

c. ESR-4 circuit board failure.

d. Slidewire equipped drive with

ESR-4 board calibrated for

CPS-2.

e. Incorrect film potentiometer

setting.

f. Control signal wired through

CPS-2 monitor relay.

a. Return Handswitch to

AUTO

position.

b. Check fuses and switches in

power panel.

c. Check for possible shorts, then

replace fuse. Use only Beck

part no. 13-2230-03 for proper

protection of triacs.

d. Return switch to AUTO position.

e. Replace ESR-4 circuit board.

See page 35.

f. Connect jumpers.

a. Check power source. Check

CPS-2 power supply voltage.

Check CPS-2 power transformer.

b. Position drive with Handwheel

and check limit switch settings.

c. Set CPS-2 rotor position. See

page 35.

d. Calibrate CPS-2. See page 27.

e. Replace CPS-2. See page 35.

a. Readjust ESR-4 zero. See Input

Signal Calibration, page 30.

b. Check continuity from terminal N

to V and M to U with Handswitch

in auto position. See wiring

diagram.

c. Check input signal.

d. Replace ESR-4 circuit board.

See page 35.

e. Check signal from CPS-2 or

potentiometer at TP3 on ESR-4.

a. Readjust ESR-4 zero. See Input

Signal Calibration, page 30.

b. Check polarity of input signal.

Terminal AA (+), Terminal BB (-).

c. Replace ESR-4 circuit board.

See page 35.

d. Cut R22 and R39 resistors and

recalibrate the ESR-4 board.

See page 30.

e. Reset film potentiometer. See

page 26.

f. Control drive position beyond

calibrated range. Use

Handswitch or Handwheel to put

drive within normal operating

range.

MAINTENANCE TROUBLESHOOTING