10-14 CRA NKSHAF T/TRANSMISSION

Crankshaft/Connection R od

•

Apply molybdenum disulfide oil:

Threads [A] of Connecting Rod Big End Cap Bolts

Seating Surface [B] of Connecting Rod Big End Cap

Nuts [C]

•

Tighten:

To rque - Connecting Rod Big End Cap Nuts: 34 N·m (3.5

kgf·m, 25 ft·lb)

Crankshaft/Connecting Rod Cleaning

•

After r emoving the connecting rods from the crankshaft,

clean them with a high flash-point solvent.

•

Blow the crankshaft oil passages with compressed air to

remove any foreign particles or residue that may have

accumulated in the passages.

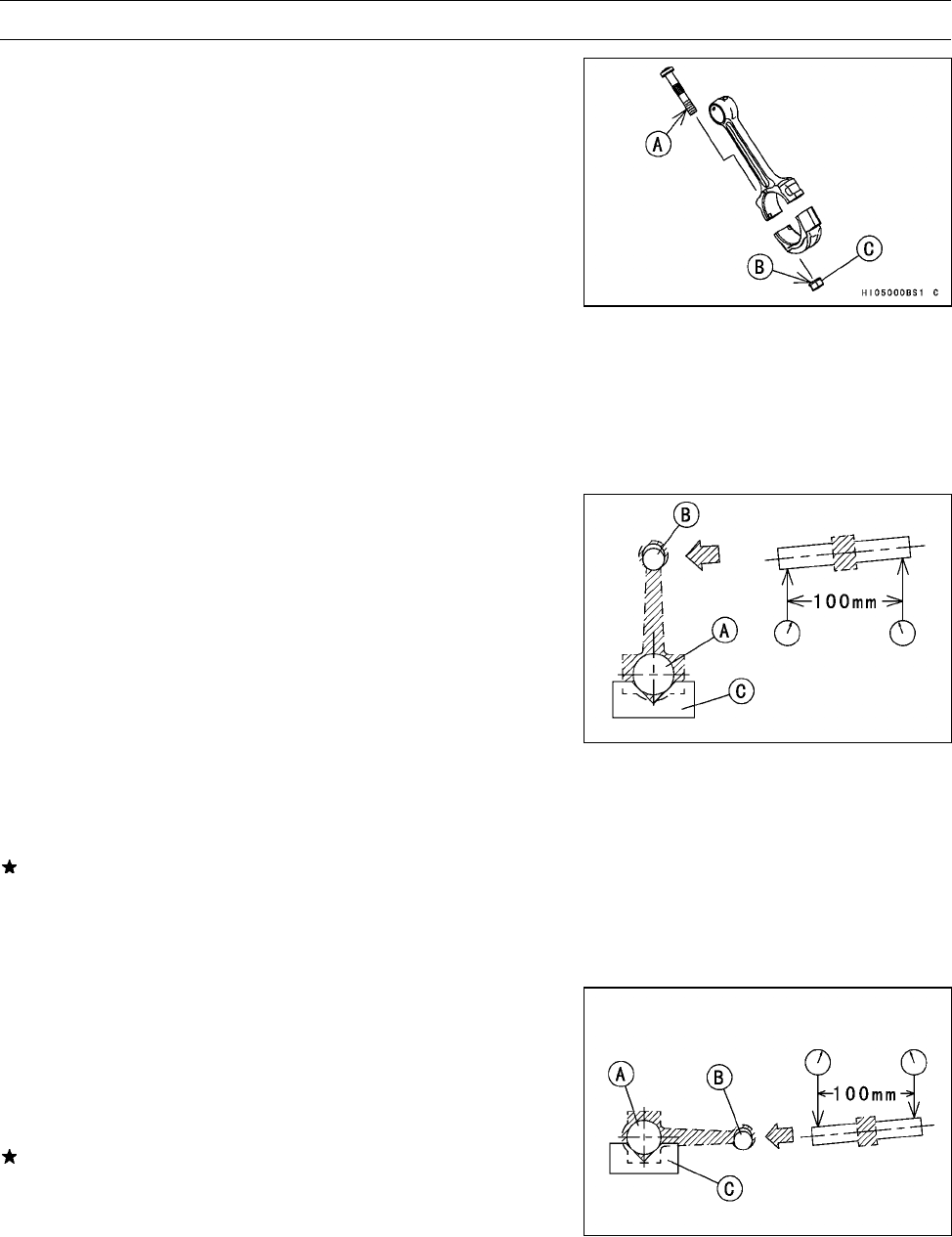

Connecting Rod Bend

•

Remove the connecting rod big end bearing inserts, and

reinstall the connecting rod big end cap.

•

Select an arbor [A] of the same diameter as the connect-

ing rod big end, and insert the arbor through the connect-

ing r od big end.

•

Select an arbor of the same diameter as the piston pin

and at least 100 mm (3.94 in.) long, and insert the arbor

[B] through the connecting rod small end.

•

On a surface plate, set the big-end arbor on a V block [C].

•

With the connecting rod held vertically, use a height

gauge to measure the difference in the height of the

arbor above the surface plate over a 100 mm (3.94 in.)

length to determine the amount of connecting rod bend.

If connecting rod bend exceeds the service limit, the con-

necting rod must be replaced.

Connecting Rod Bend

Service Limit: TIR 0.2/100 mm (0.008/3.94 in.)

Connecting Rod Twist

•

With the big-end arbor [A] still on the V block [C], hold the

connecting rod horizontally and measure the amount that

the arbor [B] varies from being parallel with the surface

plate over a 100 mm (3.94 in.) length of the arbor to de-

termine the amount of connecting rod twist.

If connecting rod twist exceeds the service limit, the con-

necting rod must be replaced.

Connecting Rod Twist

Service Limit: TIR 0.2/100 mm (0.008/3.94 in.)