©2011 Edelbrock LLC

Part #1596, 1597, 1598 & 1599

Brochure #63-1598

Rev. 2/11 - AJ/mc

Edelbrock E-Force Supercharger System for

the 2010 Camaro SS

Installation Instructions

Page 10

32. Use a pair of hose clamp pliers to loosen the clamp

retaining the vacuum hose to the brake booster fitting and

disconnect the hose. It will be removed with the manifold.

33. Lift the rear of the manifold over the oil pressure

sensor and pull it forward to remove it. Remove the o-

ring seals from the manifold flanges and retain them for

later reuse.

34. Use a clean shop rag to wipe down the intake flange

of both cylinder heads then put a small strip of masking

tape over each port to prevent debris from entering.

35. Use a crescent wrench to remove the oil pressure

sensor from the engine valley plate.

NOTE: Steps #36 - #42 outline the procedure for

disabling the Active Fuel Management system found in

Camaros equipped with an automatic transmission.

Manual vehicles should skip ahead to step #43.

WARNING: AUTOMATIC CAMAROS EQUIPPED WITH

STANDARD, NON-AFM LIFTERS MUST USE THE

MANUAL VALLEY COVER PLATE. FAILURE TO DO SO

WILL RESULT IN ENGINE DAMAGE.

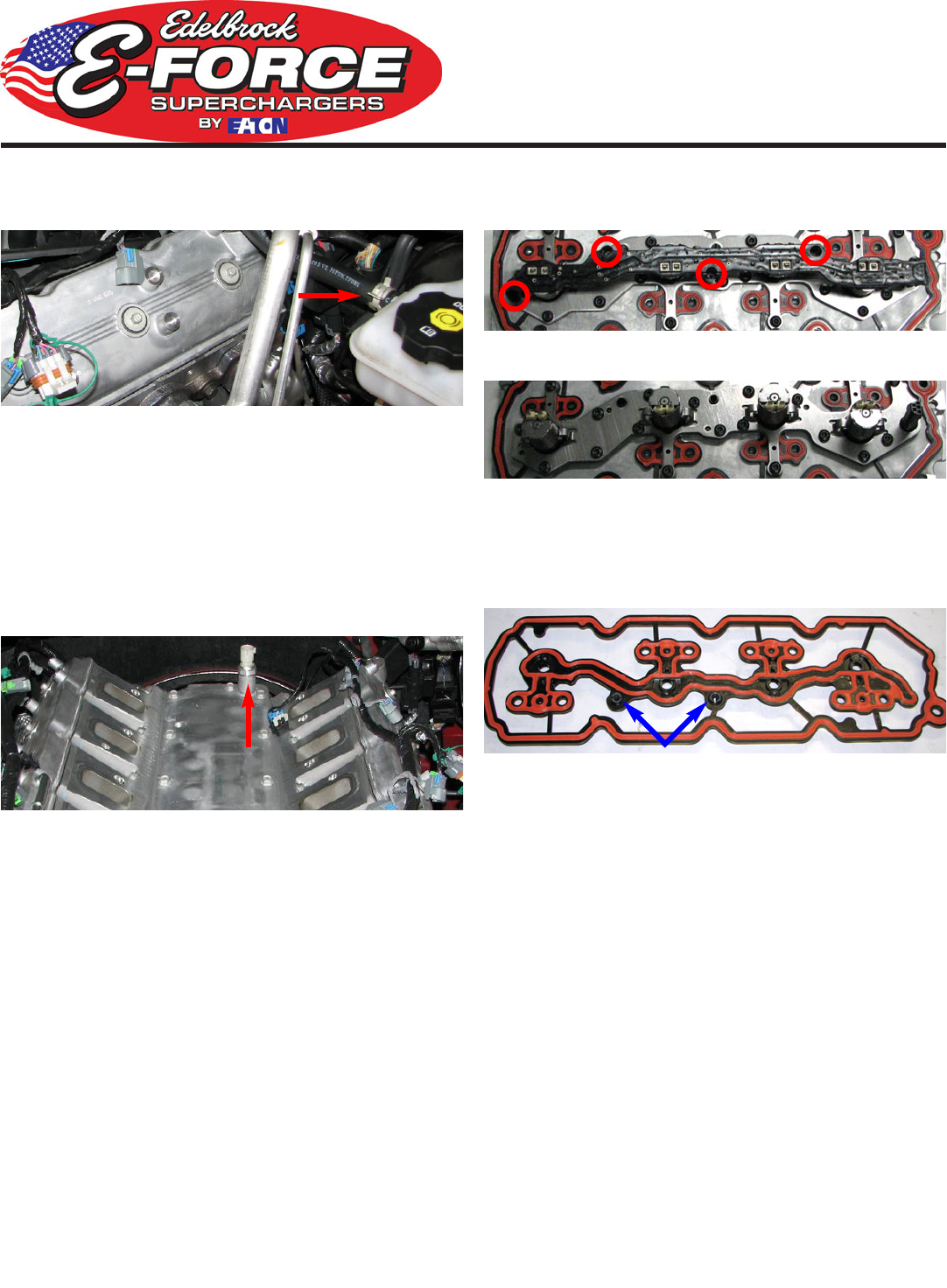

36. Use a 13mm socket to remove the eleven bolts

retaining the engine valley plate and remove the plate.

37. Use a T-20 Torx driver to remove the four bolts

retaining the plastic solenoid bracket, then pry open the

clip at the rear of the plate to remove the bracket.

38. Rotate each solenoid 90° and remove them.

39. Use a T-30 Torx driver to remove the twenty bolts

holding the steel sandwich in place and remove it.

40. Remove the plastic and rubber gasket from the valley

tray using great care not to damage the seal.

41. Trim the two tabs projecting from the gasket to the

base of their tapers. Use a file to remove any burrs then

install the gasket in the new valley plate.

42. Install the new valley plate with the gasket in place

onto the engine and proceed to step #47.

43. Use a 13mm socket to remove the eleven bolts

retaining the engine valley plate and remove the plate.

The metal and rubber gasket beneath it will be reused

and should be left in place.

44. Use a flathead screwdriver to remove the eight o-ring

seals from the underside of the valley plate.

45. Inspect each seal for damage and replace any that

have been compromised then install the seals into the

supplied valley plate.