4 - 44

ENG

CYLINDER AND PISTON

Cylinder bore “C”

95.00 ~ 95.01 mm

(3.7402 ~ 3.7406 in)

Taper limit “T” 0.05 mm (0.002 in)

Out of round “R” 0.05 mm (0.002 in)

“C” = Maximum D

“T” = (Maximum D

1

or D

2

)

– (Maximum D

5

or D

6

)

“R” = (Maximum D

1

, D

3

or D

5

)

– (Minimum D

2

, D

4

or D

6

)

• If out of specification, replace the cylinder,

and replace the piston and piston rings as

set.

2nd step:

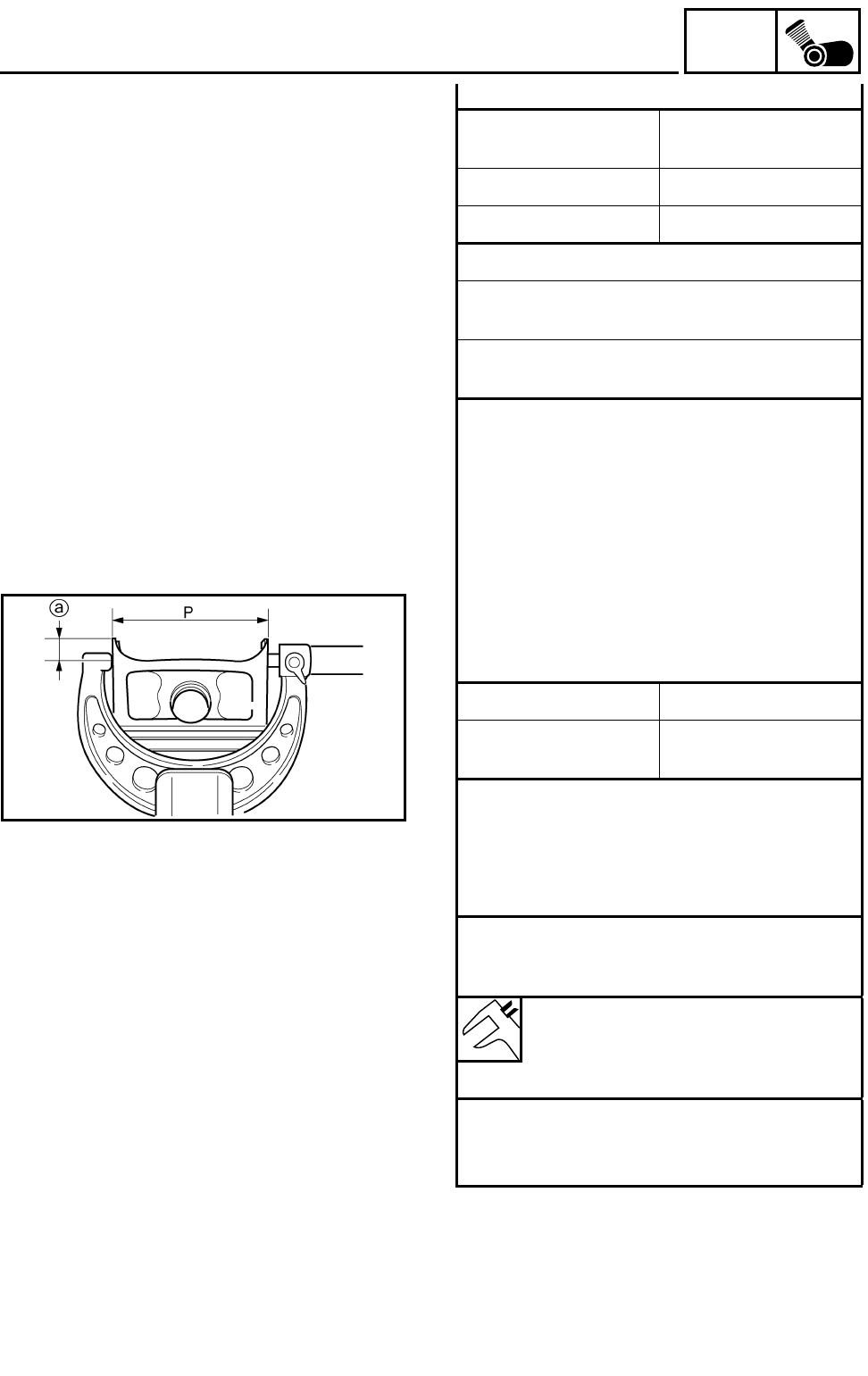

• Measure the piston skirt diameter “P” with

a micrometer.

a

8 mm (0.315 in) from the piston bottom edge

Piston size “P”

Standard

94.945 ~ 94.960 mm

(3.738 ~ 3.739 in)

• If out of specification, replace the piston

and piston rings as a set.

3rd step:

• Calculate the piston-to-cylinder clearance

with following formula:

Piston-to-cylinder clearance =

Cylinder bore “C” –

Piston skirt diameter “P”

Piston-to-cylinder clearance:

0.040 ~ 0.065 mm

(0.0016 ~ 0.0026 in)

<Limit>: 0.1 mm (0.004 in)

• If out of specification, replace the cylinder,

and replace the piston and piston rings as

set.