ENGINE AND PERIPHERALS

Overhauling the engine

10

10-86

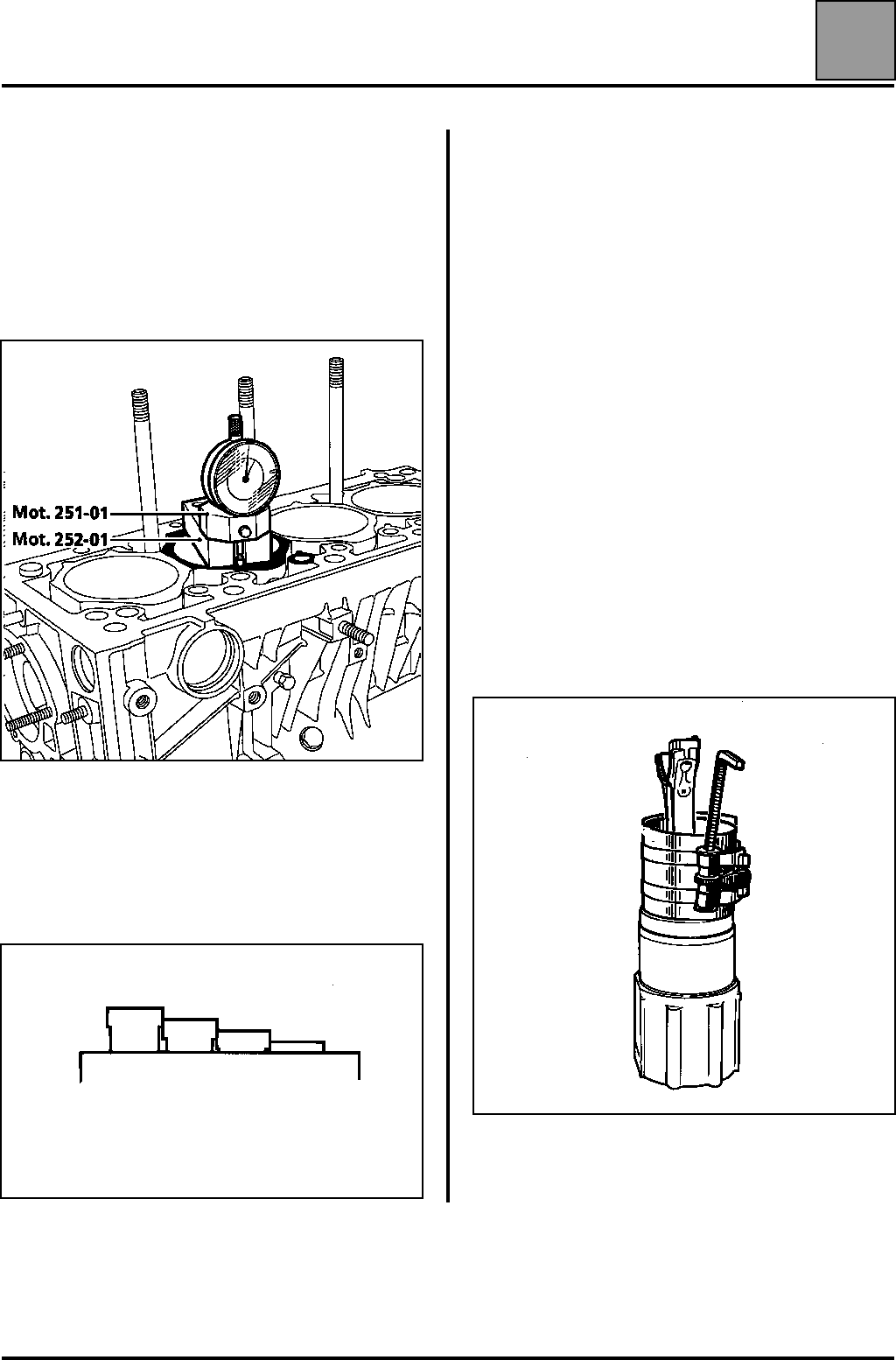

Therefore, the protrusion (X) should be checked in the

following way:

– place the cylinder liner not fitted with seals, in the

cylinder block,

– check protrusion (X) using tools Mot. 251-01 and

Mot. 252-01. It should be between 0.07 and

0.13 mm.

Position the cylinder liners so that:

– the protrusion is graduated from cylinder n˚ 1 to

cylinder n˚ 4 (or vice versa),

– the difference in protrusion between two

neighbouring cylinders is no more than 0.04 mm (in

tolerance).

NOTE: the parts supplied in the cylinder liner-piston

operation kit are identical to those used for this

operation. Mark the parts in each box from A to D to

ensure they remain identical.

Once the correct protrusion has been obtained,

reassemble groups A, B, C and D with the cylinder

liners, pistons and gudgeon pins and mark their

position in the cylinder block.

NOTE: If the protrusion is incorrect, check using a new

cylinder liner set to find out whether the cylinder block

or the cylinder liner is at fault.

REFITTING CYLINDER LINERS - PISTONS - CON

RODS

Oil the pistons.

Fit the piston-con rod assemblies into the cylinder

liners with the tool, paying attention to the direction

(the V towards the flywheel).

The big end surfaces must be parallel with the flat

bottom of the cylinder liner.

16528R