ENGINE AND PERIPHERALS

Overhauling the engine

10

10-100

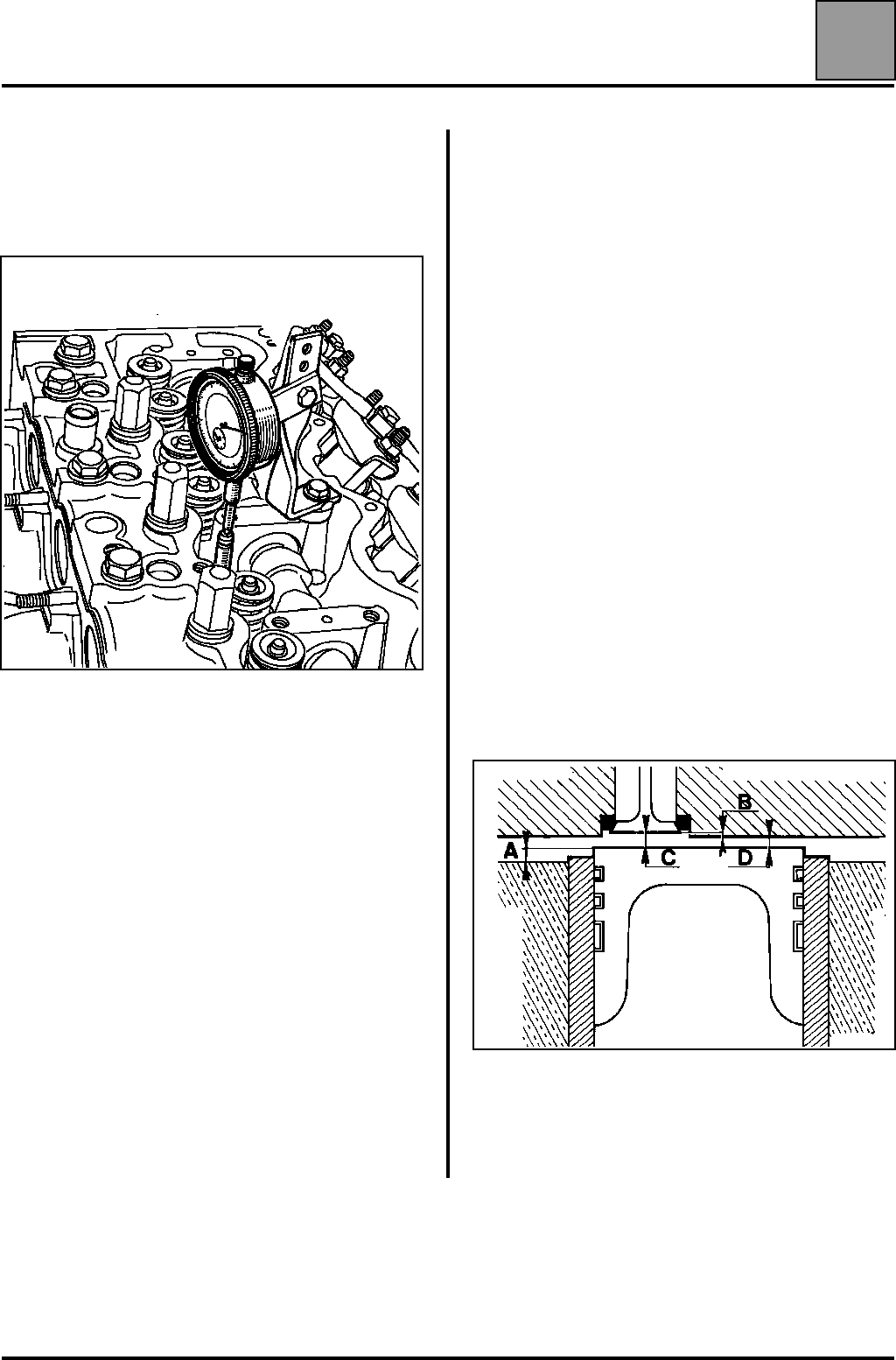

Value of the piston-cylinder head clearances

Form this dimension (piston - valve), subtract the valve

clearance value measured earlier; the result (piston -

cylinder head clearance) should be more than 0.6 mm.

Example of completed measurement, cylinder

head removed from the engine:

1) Piston protrusion (after turning the crankshaft

clockwise at the timing end)

(Measurement A):

– cylinder n˚ 1, A = 1.05 mm

– cylinder n˚ 2, A = 1.04 mm

– cylinder n˚ 3, A = 1.05 mm

– cylinder n˚ 4, A = 1.07 mm

In this case use measurement A = 1.07 mm for

cylinder 4.

This measurement being greater than 1.04 mm, fit a

cylinder head gasket 1.8 mm thick.

2) Valve clearance (measurement B)

On the inlet and exhaust valves of the 4

th

cylinder:

Inlet: B = 0.92 mm

Exhaust: B = 0.87 mm

(The clearance is between 0.80 and 1.15 mm).

In this case, use the measurement B = 0.87 mm for

the exhaust valve, it being the smaller.

Cylinder head fitted on the engine (with the cylinder

head gasket and tightened to torque):

3) Valve - piston clearance (measurement C)

On the exhaust valve stem of the 4 th cylinder

(reminder: piston at top dead centre):

C = 1.57 mm

which gives the PISTON/CYLINDER HEAD

CLEARANCE:

D = C - B = 1.57 - 0.87 = 0.7 mm

(This clearance is thus greater than 0.6 mm).

Refit:

– the camshaft (16),

– the rocker arm rail (17),

– the fuel return rail to the tank, fitted with new copper

seals.

83367S