6G7 ENGINE (E-W) -

Crankshaft, Flywheel and Drive Plate

11A-13-3

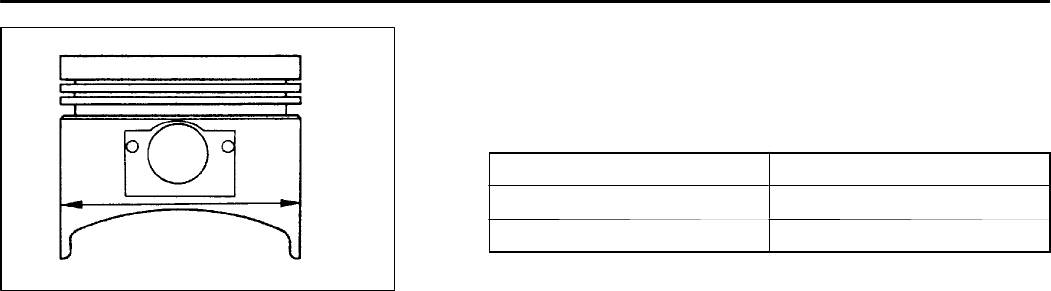

BORING CYLINDER

(1) Oversize pistons to be used should be determined on

the basis of the largest bore cylinder.

Piston size identification

Size Identification mark

0.50 mm O.S. 0.50

1.00 mm O.S. 1.00

NOTE

Size mark is stamped on the piston top.

(2) Measure outside diameter of piston to be used. Measure

it in thrust direction as shown.

(3) Based on the measured piston O.D., calculate the boring

finish dimension.

Boring finish dimension = Piston O.D. + (Clearance

between piston O.D. and cylinder) - 0.02 mm (honing

margin)

(4) Bore allcylinders tothe calculatedboring finish dimension.

Caution

D

To prevent distortion that may result from

temperature rise during honing, bore cylinders,

in the order of No. 1, No. 2, No. 3, No. 4, No. 5

and No. 6.

(5) Hone to the final finish dimension (Piston O.D. + clearance

between piston O.D. and cylinder.)

(6) Check the clearance between piston and cylinder.

Clearance between piston and cylinder:

0.02 - 0.04 mm

NOTE

When boring cylinders, finish all of four cylinders to t he

same oversize. Do not bore only one cylinder to an

oversize.

PWEE9615

E

Dec. 1996Mitsubishi Motors Corporation

6EN0554

Piston O.D.

Thrust

direction