6G7 ENGINE (E-W) -

Rocker Arms and Camshaft

11A-9-2

REMOVAL SERVICE POINTS

A

A

"

LASH ADJUSTER

(1) Before removing the rocker arms an d rocker arm shafts,

install the Special Tools to prevent the lash adjusters from

falling off.

INSPECTION

CAMSHAFT

(1) Measure the cam height.

Standard value:

IN: 37.71 mm

EX: 37.14 mm

Limit:

IN: 37.21 mm

EX: 36.64 mm

LASH ADJUSTER LEAK DOWN TEST

Caution

D

The lash adjuster is a precision part. Keep it free from

dust and other foreign matters.

D

Do not disassemble lash adjuster.

When cleaning lash adjuster, use clean diesel fuel

only.

(1) Immerse the lash adjuster in clean diesel fuel.

(2) While lightlypushing downinnersteel ballusing theSpecial

Tool (Air bleed wire MD998442), move the plunger up

and down four or five times to bleed air.

Use of the Special Tool (Retainer MD998441) helps

facilitate the air bleeding of the rocker arm mounted type

lash adjuster.

(3) Remove the Special Tool (Air bleed wire MD998442) and

press the plunger. If the plunger is hard to be pushed

in, the lash adjuster is normal. If the plunger can be pushed

in all the way readily, bleed the lash adjuster again and

test again if the plunger is still loose, replace the lash

adjuster.

Caution

D

Uponcompletion ofair bleeding,hold lash adjuster

upright to prevent inside diesel fuel from spilling.

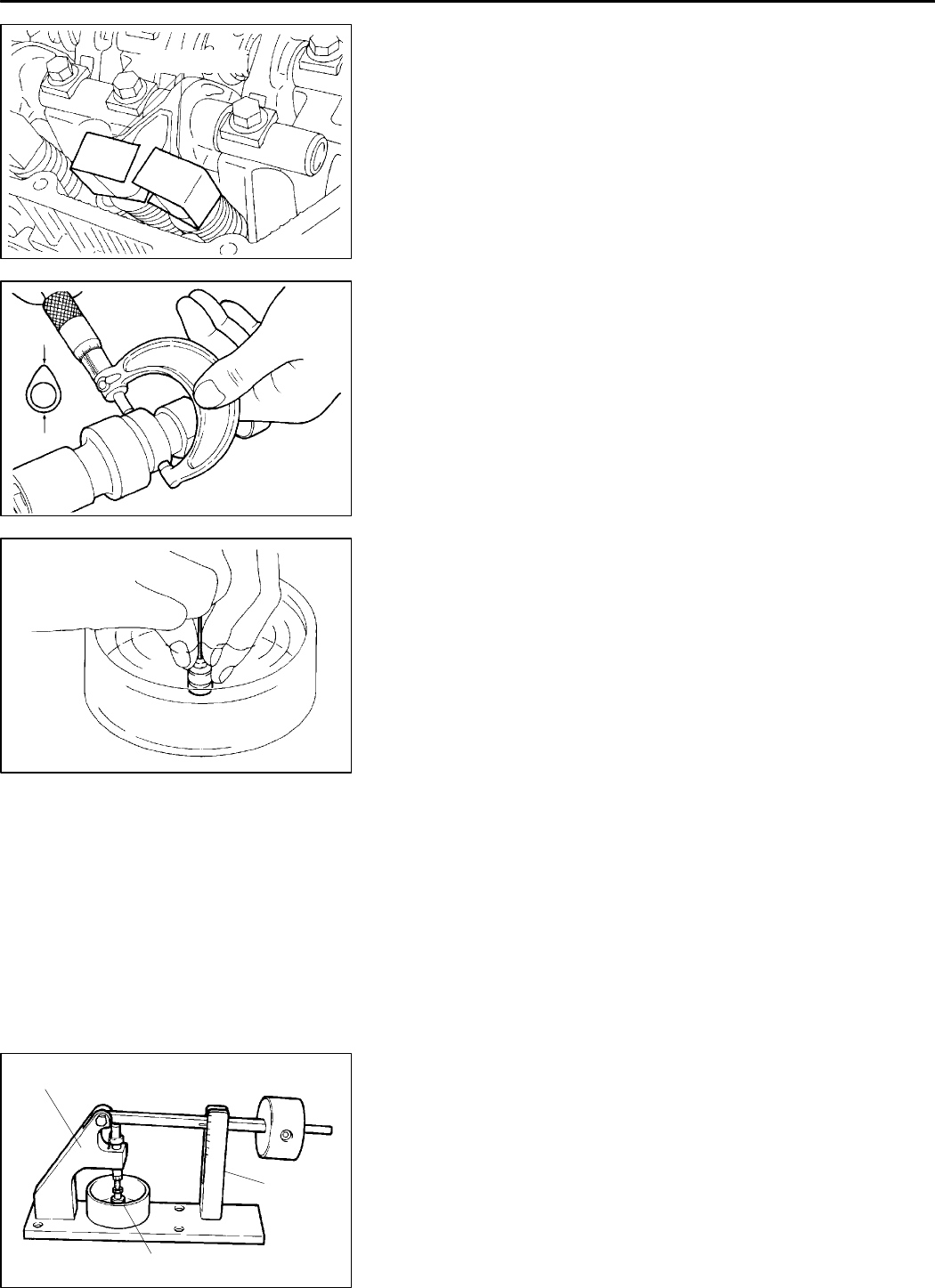

(4) After air bleeding, set lash adjuster on the Special Tool

(Leak down tester MD998440).

(5) After plunger has gone down between 0.20 to 0.50 mm,

measure time taken for it to go down a further 1 mm.

Replace if measured time is out of specification.

Standard value: 4 - 20 seconds/1 mm

<Diesel fuel at 15 - 20

_

C>

PWEE9615

E

Dec. 1996Mitsubishi Motors Corporation

6AE0160

MD998443

9EN0058

7EN0721

Diesel fuel

8EN0059

MD998440

Lash adjuster

Graduation

(1 mm)