6G7 ENGINE (E-W) -

Piston and Connecting Rod

11A-12-6

"

D

A

PISTON AND CONNECTING ROD

(1) Liberally coat the circumference of the piston, piston ring,

and oil ring with engine oil.

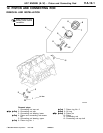

(2) Arrange the piston ring and oil ring gaps (side rail and

spacer) as shown in the figure.

(3) Rotate the crankshaft so that the crank pin is positioned

at the centre line of the cylinder bore.

(4) Use suitable thread protectors on connecting rod bolts

before inserting piston and connecting rod assembly into

cylinder block.

Care must be taken not to nick crank pin.

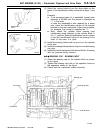

(5) Using a suitable piston ring compressor tool, install piston

and connecting rod assembly into cylinder block.

Caution

D

Install the piston with the front mark (arrow mark)

on the top of the piston facing towards the engine

front (timing belt side).

"

E

A

CONNECTING ROD CAP

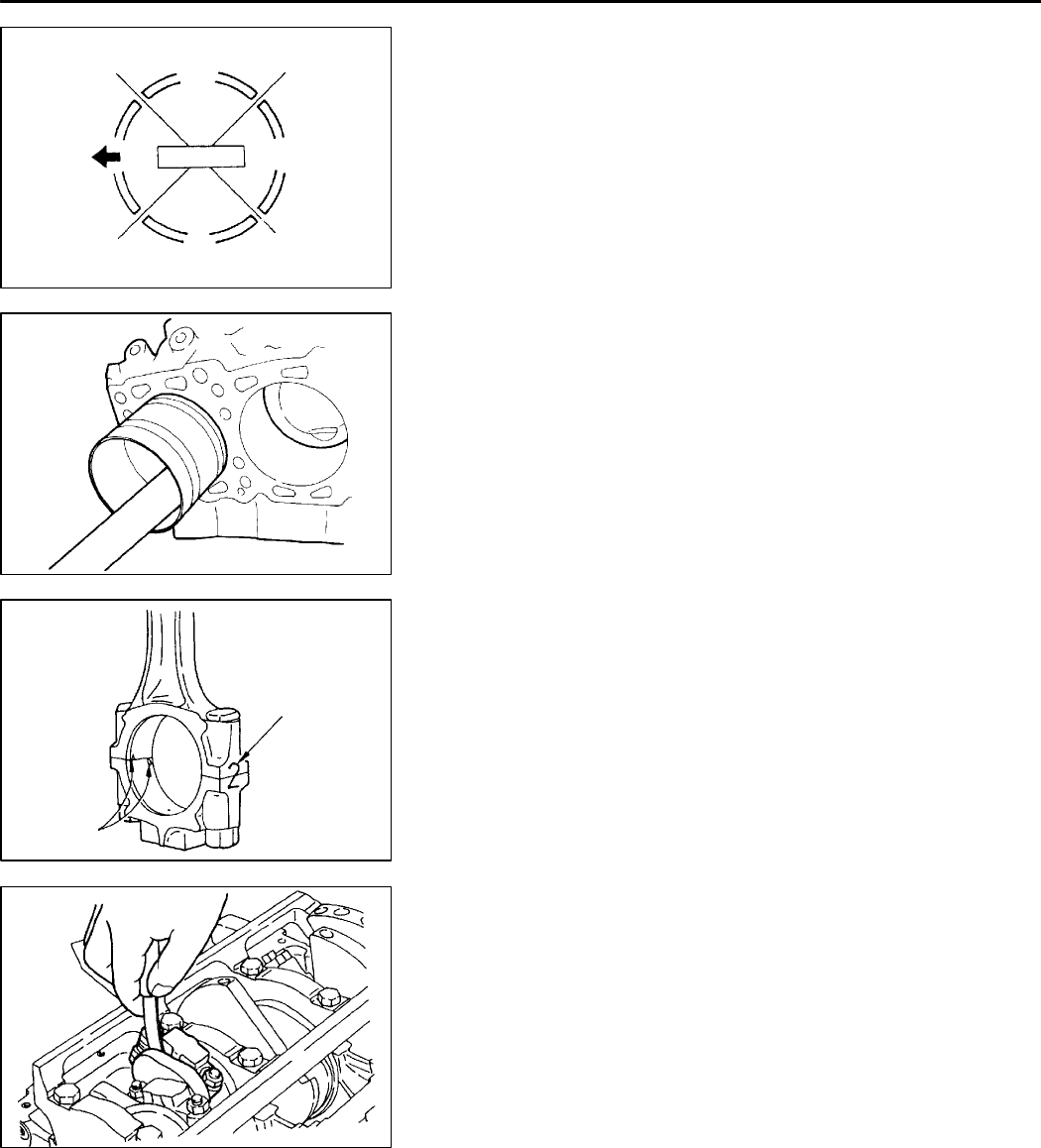

(1) Mate the correct bearing cap with the correct connecting

rod by checking with th e alignment marks marked during

disassembly. If a new connecting rod is used which has

no alignment mark, position the notches for locking the

bearing on the same side.

(2) Check if the thrust clearance in the connecting rod big

end is correct.

Standard value: 0.10 - 0.25 mm

Limit: 0.4 mm

PWEE9615

E

Dec. 1996Mitsubishi Motors Corporation

6EN0549

Upper side rail

No. 2 ring gap

and spacer gap

Lower side rail

No. 1

Piston pin

7EN0032

7EN0453

Cylinder

number

Notches

7EN0454