6G7 ENGINE (E-W) -

Crankshaft, Flywheel and Drive Plate

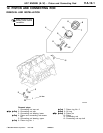

11A-13-2

INSPECTION

CRANKSHAFT OIL CLEARANCE (PLASTIGAUGE

METHOD)

NOTE

If the oil clearance exceeds the limit, replace the bearing,

and crankshaft if necessary.

This crankshaft oil clearance can be measured easily by using

a plastic gauge, as follows:

1 Remove oil and grease a nd any other foreign material

from crankshaft journal and bearing inner surface.

2 Install the crankshaft.

3 Cut the plastigauge to the same length as the width of

bearing and place it on journal in parallel with its axis.

4 Gently place the crankshaft bearing cap over it and tighten

the bolts to the specified torque.

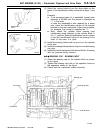

5 Remove the bolts and gently remove the crankshaft

bearing cap.

6 Measure the width of the crushed plastic gauge at its

widest section by using a scale printed on the plastigauge

package.

Standard values: 0.02 - 0.04 mm

Limit: 0.1 mm

CYLINDER BLOCK

(1) Visually check for scratches, rust and corrosion. Also use

flaw detecting agents and the like to check for cracks.

If there are any defects, rectify the cylinder block.

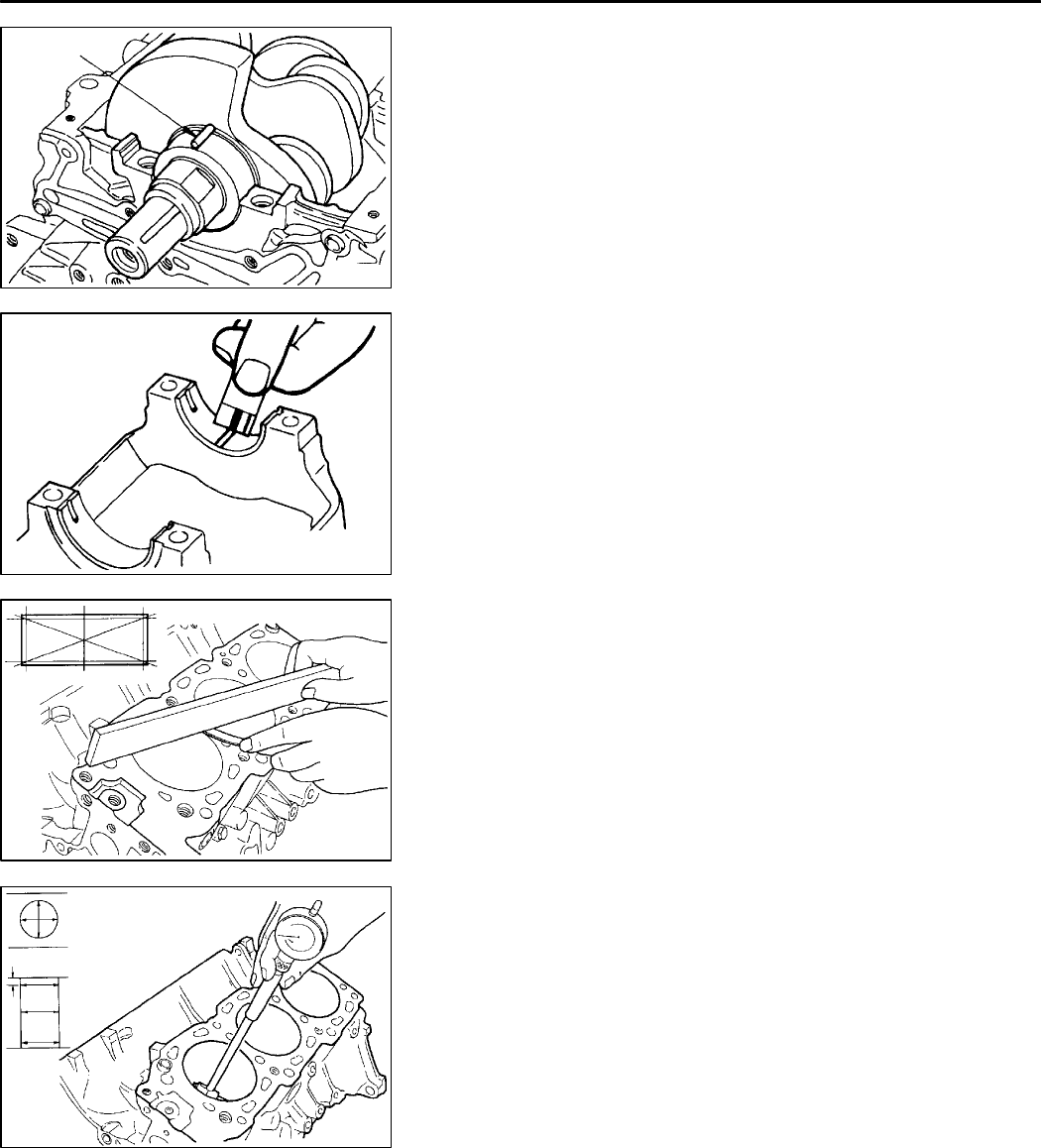

(2) Measure the flatness of the cylinder block t o p surface

with a straight edge and a thickness gauge. During

measurement, the cylinder block t op surface must be free

from gasket pieces and the like.

Standard values: 0.05 mm

Limit: 0.1 mm

(3) Check for scratches or seizure of the cylinder wall. If there

are any defects, correct (bore it a oversize) or change

the cylinder block.

(4) Measure the inside diameter and the ovalityof the cylinder.

If the cylinder is overly worn, correct it to a larger size

and change the pistons and the piston rings.

Standard value:

Cylinder inside diameter 91.1 mm

Ovality: 0.01 mm

PWEE9615

E

Dec. 1996Mitsubishi Motors Corporation

7EN0459

Plastigauge

7EN0141

7EN0460

7EN0461

12 mm