6G7 ENGINE (E-W) -

Piston and Connecting Rod

11A-12-4

INSTALLATION SERVICE POINTS

"

A

A

PISTON PIN

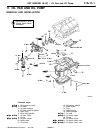

(1) Measurethe dimensionsofthefollowingpartsandportions:

A: Piston pin mounting portion

B: Distance between piston bosses

C: Piston pin

D: Connecting rod

(2) Calculate by substituting each measured value into the

following equation:

(A - C) - (B - D)

2

L=

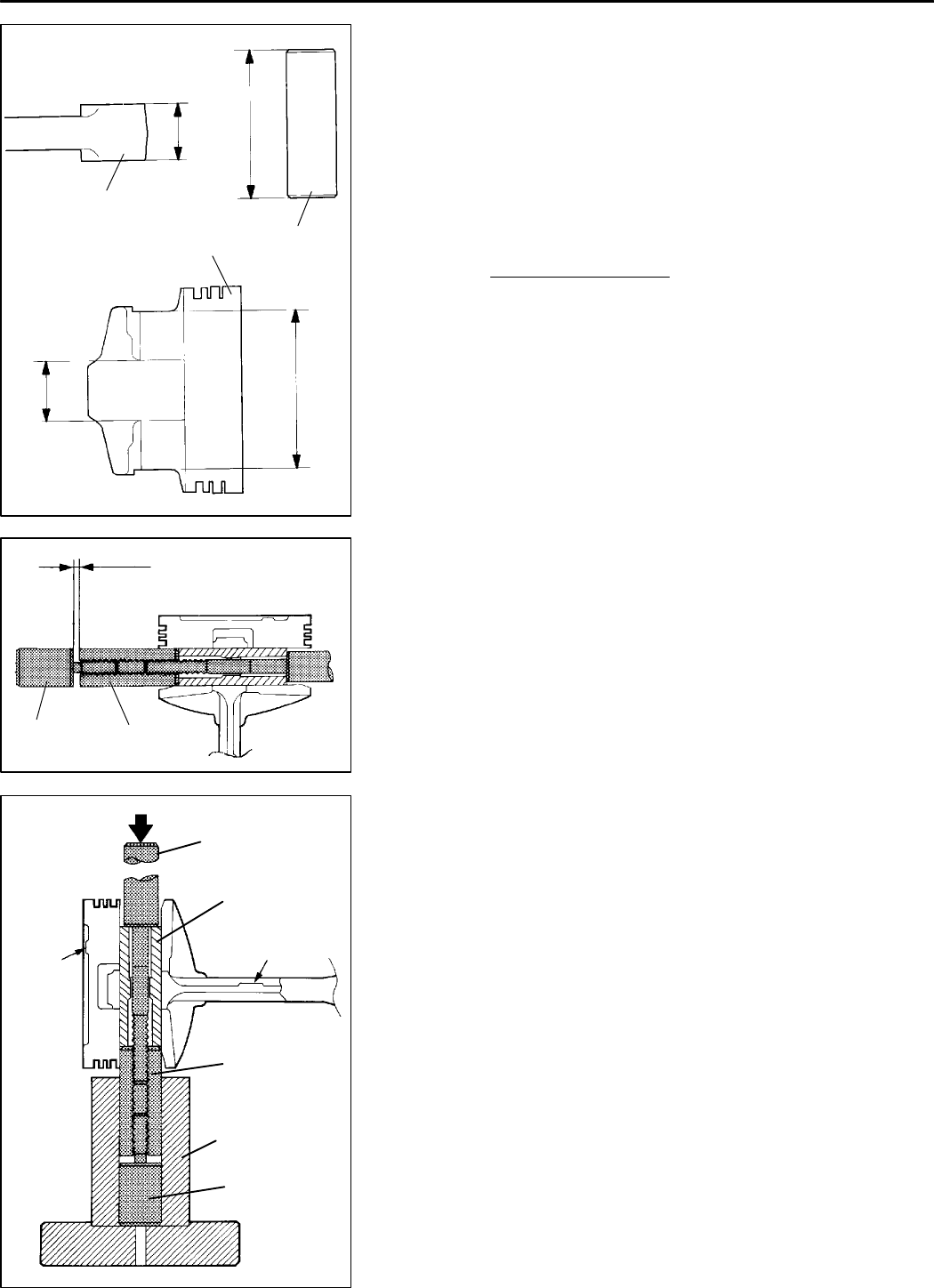

(3) Insert the special push rod tool into the piston pin a nd

attach guide A to it.

(4) Combine the piston and the connecting rod, matching

their front marks.

(5) Apply engine oil to the outer periphery of the piston pin.

(6) Insert the side of the piston pin guide A attached per

Step (3) into the pin hole from the side of the piston

containing the front mark.

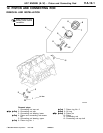

(7) Screw guide B into guide A until they are distance L

(obtained per Step (2) above) plus 3 mm apart as shown.

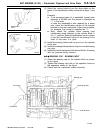

(8) Use special tools to set the piston pin to a special tool

piston setting base with the front mark of the piston facing

up.

(9) Press fit the piston pin with apress. Whenthe loadrequired

for press fitting the piston pin is below the standard value,

change the piston pin (piston assembly) or the connecting

rod or both.

Standard values: 7,350 - 17,200 N

PWEE9615

E

Dec. 1996Mitsubishi Motors Corporation

Connecting rod

Piston

Piston pin

7EN0432

D

C

B

A

3mm+L

Guide B

Guide A

7EN0433

Push rod

Piston pin

Front mark

Front

mark

Guide A

Base

Guide B

7EN0391