6G7 ENGINE (E-W) -

Cylinder Head and Valves

11A-10-3

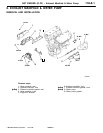

INSPECTION

CYLINDER HEAD

(1) Checkthe cylinderheadforwater leaks,gas leaks,damage

or cracks before washing it.

(2) Completely remove oil, fur, sealer, carbon and the like.

After washing the oil passages, blow air through them

to make sure they are not clogged.

(3) To ensure flatness of the cylinder head bottom surface,

measure the distortion of the surface using a straight edge

and a thickness gauge. When the distortion exceeds the

specifications, correct by grinding the surface.

Standard values of bottom surface distortion:

Within 0.03 mm

Limit: 0.2 mm

Grinding limit: 0.2 mm

Height of the cylinder head: 120 mm

Caution

D

The cylinder head bottom surface may be ground

to within 0.2 mm of the mating cylinder block.

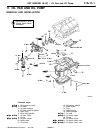

VALVES

(1) When contact between the valve and the valve seat is

improper, unbalanced or nonexistent, correct the valve

seat.

(2) Change the valve when the margin doesn’t meet the

specifications.

Standard value: Intake 1.0 mm

Exhaust 1.2 mm

Limit: Intake 0.5 mm

Exhaust 0.7 mm

(3) Measure the total length of the valve. If the measured

value is below the limit, change the valve.

Standard value: Intake 112.30 mm

Exhaust 114.11 mm

Limit: Intake 111.80 mm

Exhaust 113.61 mm

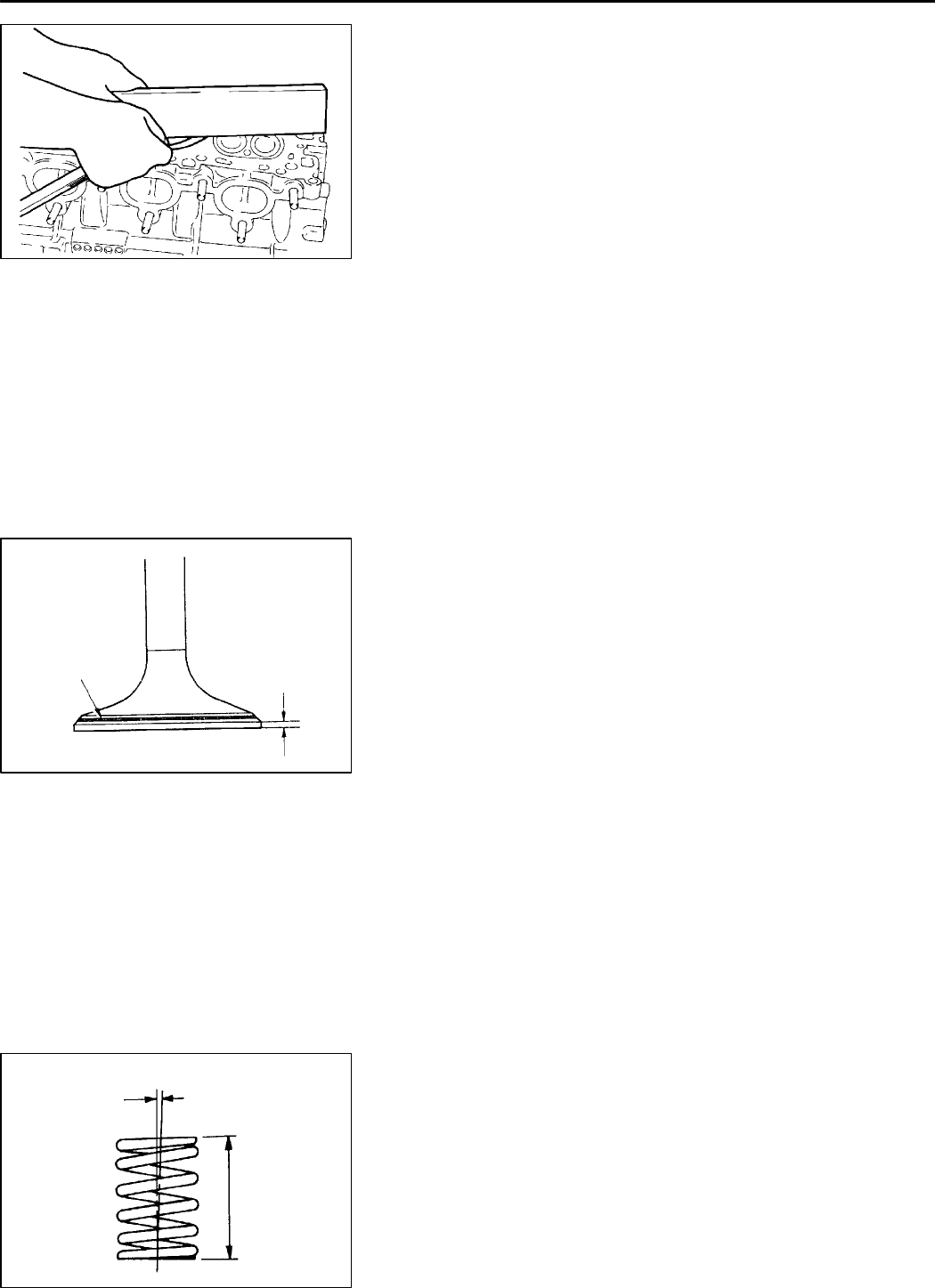

VALVE SPRING

(1) Measure the free height of the valve spring. When the

measured value exceeds the specified limit, change the

valve spring.

Standard value: 51.0 mm

Limit: 50.0 mm

(2) Measure the perpendicularity of the valve spring. When

the measured value exceeds the specified limit, change

the valve spring.

Standard value: 2

_

max.

Limit: 4

_

PWEE9615

E

Dec. 1996Mitsubishi Motors Corporation

7EN0258

6EN0542

Margin

Contact to be at

the centre of the

valve face.

1EN0264

Free height

2

_