4G6 ENGINE (E-W) -

Piston and Connecting Rod

11A-11-5

"

C

A

PISTON RING NO. 2 / PISTON RING NO. 1

INSTALLATION

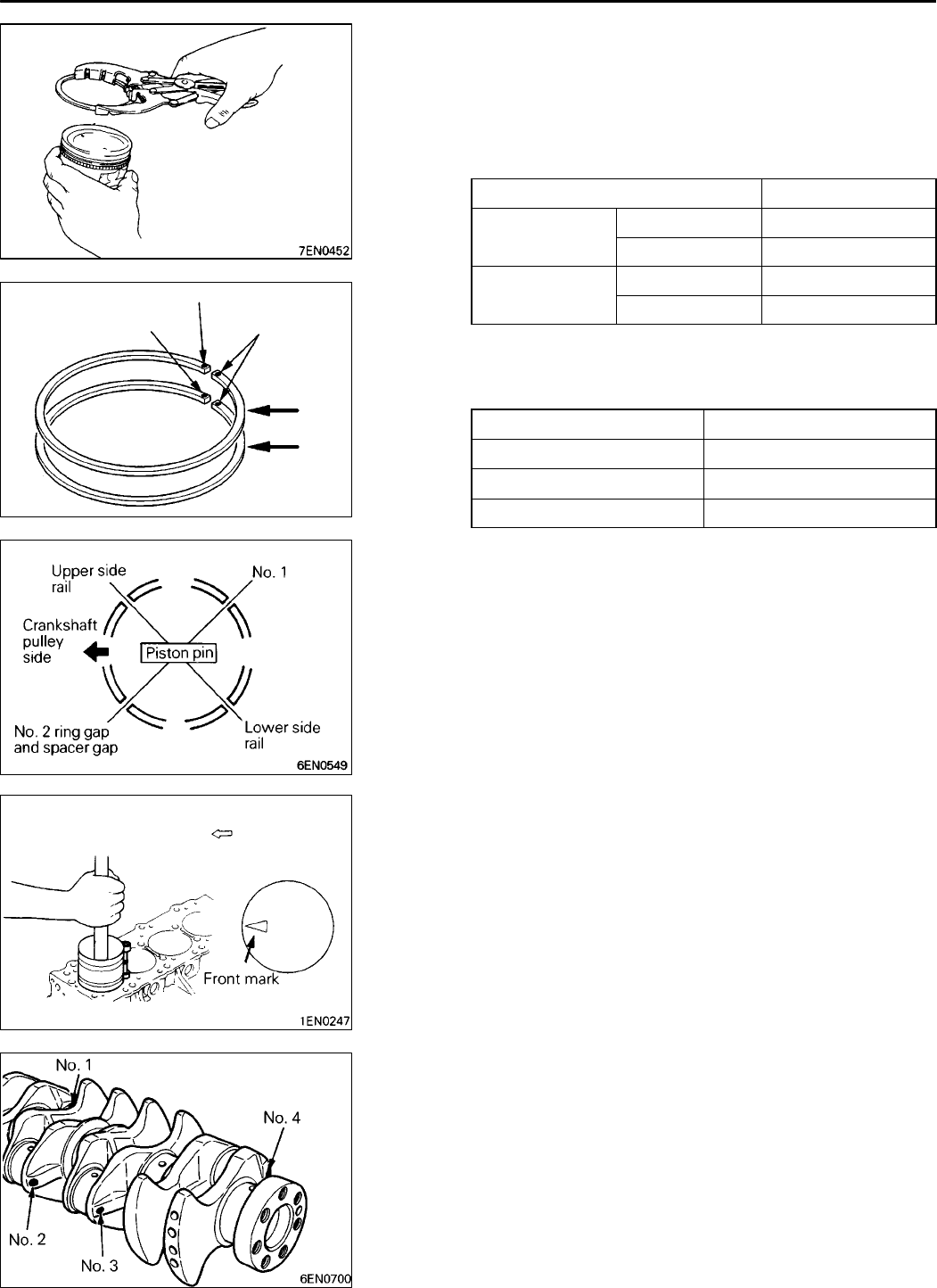

(1) Using piston ring expander, fit No. 2 and then No. 1 piston

ring into position.

NOTE

1. The ring end is provided with identification mark.

Item Identification mark

No. 1 ring 4G63 SOHC 1R

4G64 GDI T

No. 2 ring 4G63 SOHC 2R

4G64 GDI 2T

2. Install piston rings with identification mark facing up,

to the piston crown side.

3. Size marks on position rings are as follows.

Size Size mark

Standard None

0.50 mm oversize 50

1.00 mm oversize 100

"

D

A

PISTON AND CONNECTING ROD ASSEMBLY

INSTALLATION

(1) Liberally coat engine oil on the circumference of the piston,

piston ring, and oil ring.

(2) Arrange the piston ring and oil ring gaps (side rail and

spacer) as shown in the figure.

(3) Rotate the crankshaft so that crank pin is on the center

of cylinder bore.

(4) Use suitable thread protectors on the connecting rod bolts

before inserting piston and connecting rod assembly into

the cylinder block.

Care must be taken not to nick the crank pin.

(5) Using a suitable piston ring compressor tool, install the

piston and connecting rod assembly into the cylinder block.

"

E

A

CONNECTING ROD BEARINGS INSTALLATION

When the bearing needs replacing, select and install a proper

bearing by the following procedure.

(1) Measure the crankshaft pin diameter and confirm its

classification from the following table. In the case of a

crankshaft supplied as a service part, identification colors

of its pins are painted at the positions shown in the

illustration.

RevisedPWEE9616-A

E

Aug. 1998Mitsubishi Motors Corporation

9EN0524

Identification mark

Identification mark

Side mark

No. 1

No. 2

Timing belt side

RevisedPWEE9616-A

E

Aug. 1998Mitsubishi Motors Corporation