AUTO TRANS DIAGNOSIS - 01M

Article Text (p. 45)

1996 Volkswagen Golf

For Volkswagen Technical Site

Copyright © 1998 Mitchell Repair Information Company, LLC

Thursday, August 19, 1999 11:28PM

5) Add dished washer thickness to distance measured in step

3). Subtract .007" (.180 mm) to obtain shim thickness for desired

roller bearing preload. Shims are available in thickness ranging from

.040-.106" (1.00-2.70 mm), in .001" (.025 mm) increments.

6) Install selected shim. Install dished washer with curved

side facing fastener nut. Apply ATF to bearings. Install and tighten

fastener nut to 184 ft. lbs. (250 N.m) to seat bearings.

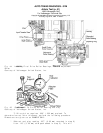

7) Using INCH-lb. torque wrench, rotate torque wrench at

least 8 turns to determine turning torque. Measure combined turning

torque of pinion and input transfer gear roller bearings. See Fig. 46.

See INPUT TRANSFER GEAR ROLLER BEARING SPECIFICATIONS table.

INPUT TRANSFER GEAR ROLLER BEARING SPECIFICATIONS

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

Application Turning Torque

New Bearings

Without Drive Pinion Bearings ... 18 INCH Lbs. (2.0 N.m)

With Drive Pinion Bearings .. (1) 27 INCH Lbs. (3.0 N.m)

Used Bearings ............. (2) Same As Before Disassembly

(1) - Based on a drive pinion torque of 9 INCH Lbs. (1.0 N.m).

(2) - Recorded during disassembly. See FINAL DRIVE & TRANSFER

GEARS under TRANSAXLE DISASSEMBLY.

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ

8) Remove fastener nut. If necessary, select a shim and

recheck roller bearing preload. If roller bearing preload is okay,

apply Locking Compound (AMV 100 01) to shaft side of roller bearing.

9) Align lugs with notches of opposite roller bearing. See

Fig. 48. Install axial needle bearing with flat side facing drive

shaft . Engage parking gear lug. Install fastener nut and tighten to

184 ft. lbs. (250 N.m).

Final Drive Assembly

1) Oil bearings and place differential assembly inside

transaxle. Install seals, "O" rings and new bearing races (if

required) to bearing carrier and bearing adjuster ring.

2) Install and tighten bearing carrier to 111 ft. lbs. (150

N.m). Install locking tab.

3) Install bearing adjuster ring. Tighten adjuster ring. See

Fig. 51. If using original bearings, tighten bearing adjuster ring to

m arks made during disassembly.

4) If using new bearings, differential or bearing carrier,

tighten bearing adjuster ring to 37 ft. lbs. (50 N.m). Turn bearing

adjuster ring 5 locking lugs tighter. Install locking tab. See

Fig. 51.

5) Using INCH-lb. torque wrench, rotate torque wrench at

least 8 turns to determine turning torque. Measure combined turning

torque of pinion, input transfer gear and differential side roller

bearings. See Fig. 46. See DIFFERENTIAL ROLLER BEARING SPECIFICATIONS