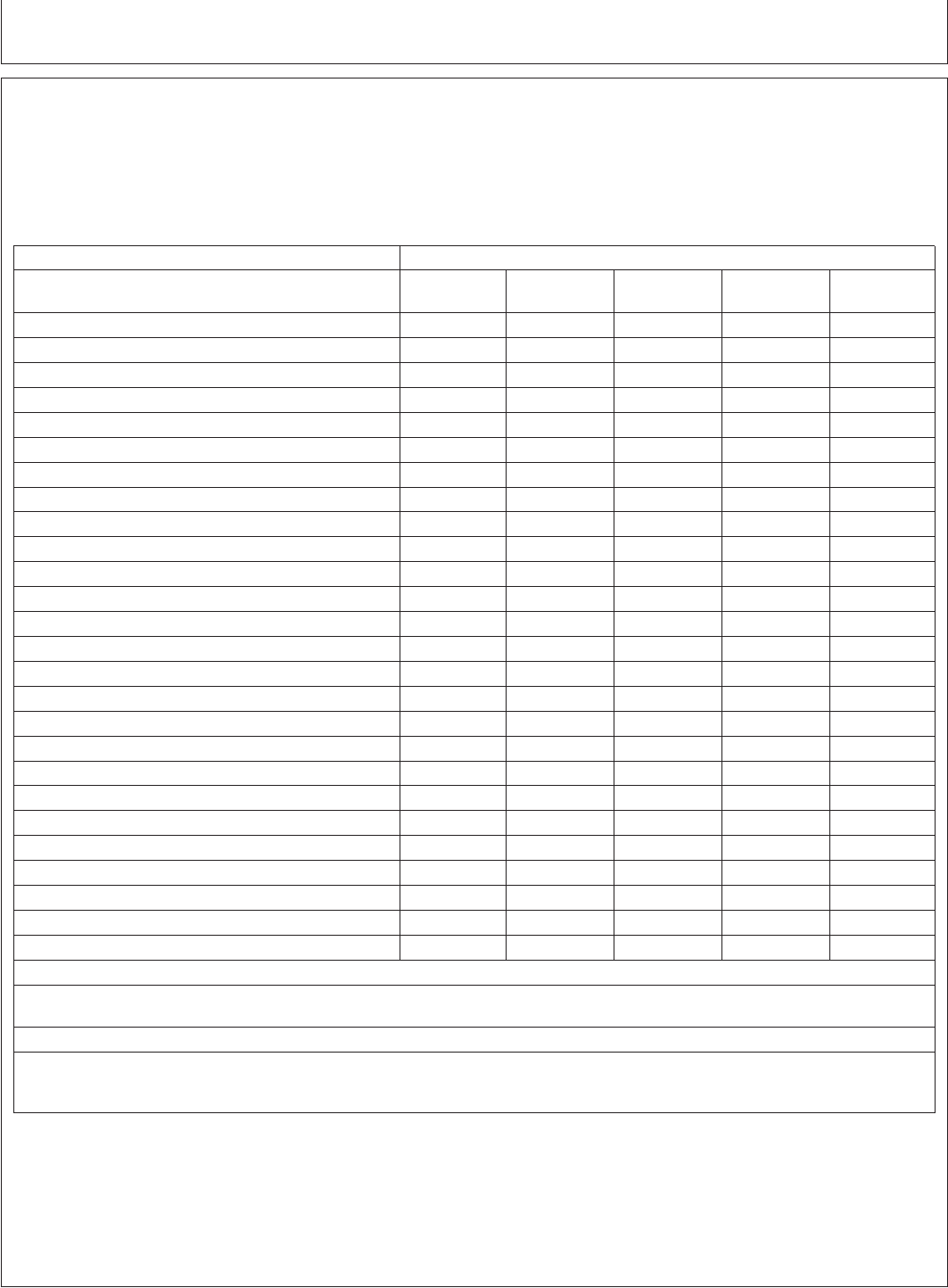

Lubrication and Maintenance

OURGP11,0000006 –19–13OCT06–1/2

Lubrication and Maintenance Service Interval

Chart—Standard Industrial Engines

NOTE: The service intervals below are for standard

industrial engines. See details in Sections which

follow these charts.

Lubrication and Maintenance Service Intervals

250 Hour/ 500 Hour/ 2000 Hour/

Item Daily 6 Month 12 Month 24 Month As Required

Check Engine Oil and Coolant Level •

Check Fuel Filter(s)/Water Separator Bowl •

Check Air Cleaner Dust Unloader Valve & Indicator

a

•

Perform Visual Walkaround Inspection •

Service Fire Extinguisher •

Change Engine Oil And Replace Oil Filter

b

•

Check Engine Mounts •

Service Battery •

Check Manual Belt Tensioner and Belt Wear •

Clean Crankcase Vent Tube •

Check Air Intake Hoses, Connections, & System •

Replace Single or Dual Fuel Filter Elements •

Check Automatic Belt Tensioner and Belt Wear •

Check Engine Speeds •

Check Engine Electrical Ground Connection •

Check Cooling System •

Coolant Solution Analysis-Add SCAs as required •

Pressure Test Cooling System •

Check Crankshaft Vibration Damper

(6.8 L Engines)

c

•

Flush Cooling System

d

•

Test Thermostats •

Check and Adjust Engine Valve Clearance •

Add Coolant •

Replace Air Cleaner Elements •

Replace Poly-Vee Belt •

Check Fuses •

a

Replace primary air cleaner element when restriction indicator shows a vacuum of 625 mm (25 in.) H2O.

b

Change the oil for the first time after 100 hours maximum of break-in operation. For subsequent oil and filter intervals, see recommendations

in section 10.

c

Replace crankshaft damper every 4500 hours or 60 months, whichever occurs first.

d

If John Deere COOL-GARD is used, the flushing interval may be extended to 3000 hours or 36 months. If John Deere COOL-GARD is used

and the coolant is tested annually AND additives are replenished as needed by adding a supplemental coolant additive, the flushing interval

may be extended to 5000 hours or 60 months, whichever occurs first.

20-2

110306

PN=64

Continued on next page