Lubrication & Maint./2000 Hour/24 Month

DPSG,RG41165,137 –19–16JAN02–1/5

Check and Adjust Valve Clearance

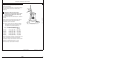

RG7408 –UN–06AUG96

Flywheel Housing Timing Holes

A—Timing/Rotation Hole

B—Timing Pin Hole

CAUTION: To prevent accidental starting of

engine while performing valve adjustments,

always disconnect NEGATIVE (—) battery

terminal.

IMPORTANT: Valve clearance MUST BE checked and

adjusted with engine COLD.

1. Remove rocker arm cover and crankcase ventilator

tube.

IMPORTANT: Visually inspect contact surfaces of

valve tips and rocker arm wear pads.

Check all parts for excessive wear,

breakage, or cracks. Replace parts that

show visible damage.

Rocker arms that exhibit excessive

valve clearance should be inspected

more thoroughly to identify damaged

parts.

2. Remove plastic plugs or cover plate from engine

timing/rotation hole (A) and timing pin hole (B).

NOTE: Some engines are equipped with flywheel

housings which do not allow use of an engine

flywheel rotation tool. These engines may be

rotated from front nose of engine, using JDG966

Crankshaft Front/Rear Rotation Adapter.

3. Using JDE83 or JD81-1 Flywheel Turning Tool, rotate

engine flywheel in running direction (clockwise viewed

from front) until No. 1 cylinder is at TDC compression

stroke. Insert JDG1571 or JDE81-4 Timing Pin in

flywheel.

If No.1 cylinder rocker arms are loose, the engine is at

No. 1 TDC compression.

If No. 1 cylinder rocker arms are not loose, rotate

engine one full revolution (360°)toNo.1TDC

compression.

40-10

110306

PN=103

Continued on next page