Lubrication & Maintenance/500 Hour/12 Month

OURGP12,000004A –19–28JUL04–3/3

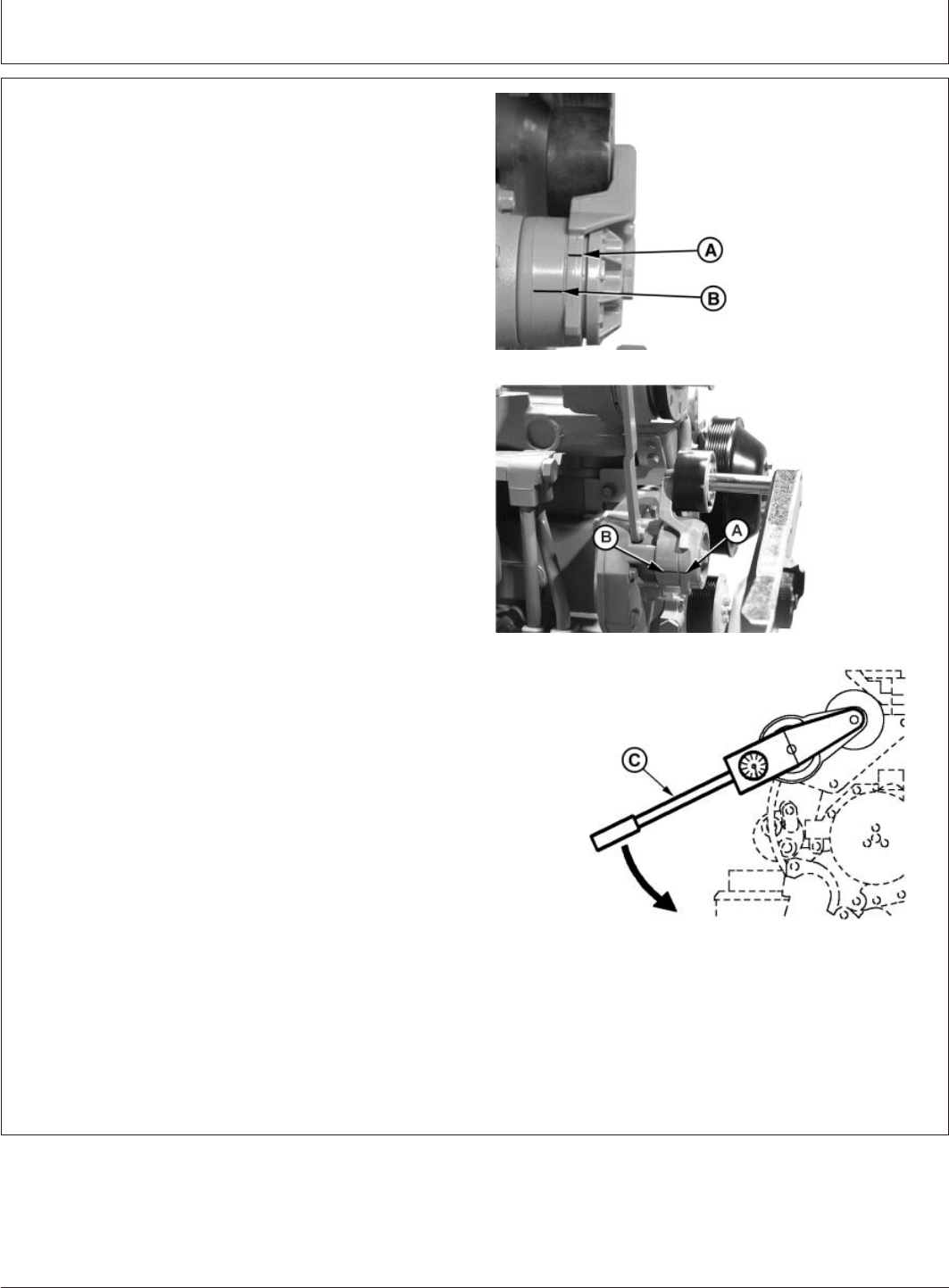

RG7977 –UN–14NOV97

Marks on Tensioner

RG12054 –UN–08JAN02

Align Marks

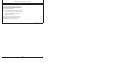

RG12065 –UN–28JAN02

Align Torque Wrench With Pulley And Tensioner

A—Mark On Swing Arm

B—Mark On Tensioner Mounting Base

C—Torque Wrench

Checking Tensioner Spring Tension

A belt tension gauge will not give an accurate measure of

the belt tension when automatic spring tensioner is used.

Measure tensioner spring tension using a torque wrench

and procedure outlined below:

NOTE: Later engines have a 12.7 mm (1/2 in.) square

drive hole in tensioner, so no socket drive is

required.

1. Release tension on belt using a breaker bar and

socket (if required) on tension arm. Remove belt from

pulleys.

2. Release tension on tension arm and remove breaker

bar.

3. Put a mark (A) on swing arm of tensioner as shown.

4. Measure 21 mm (0.83 in.) from (A) and put a mark (B)

on tensioner mounting base.

5. Install torque wrench (C) so that it is aligned with

center of pulley and tensioner. Rotate the swing arm

with the torque wrench until marks (A and B) are

aligned.

6. Record torque wrench measurement and compare with

specification below. Replace tensioner assembly as

required.

Specification

Spring Tension—Torque 18-22 N•m (13-16 lb-ft).......................................

NOTE: Threads on earlier belt tensioner roller cap screw

are LEFT-HAND threads.

35-8

110306

PN=88