Lubrication & Maint./2000 Hour/24 Month

DPSG,RG41165,137 –19–16JAN02–2/5

4. With engine lock-pinned at TDC of No. 1 piston’s

compression stroke, check valve clearance to following

specifications. (Use sequence for 4-cylinder or

6-cylinder engines as outlined on next page.)

Specification

Intake Valve Clearance For

Checking (Rocker Arm-to-Valve

Tip) (Engine Cold)—Clearance 0.31—0.38 mm

(0.012—0.015 in.)

.........................................

Exhaust Valve Clearance For

Checking (Rocker Arm-to-Valve

Tip) (Engine Cold)—Clearance 0.41—0.48 mm

(0.016—0.019 in.)

.........................................

DPSG,RG41165,137 –19–16JAN02–3/5

RG7409 –UN–06AUG96

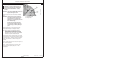

Adjusting Valves

A—Adjusting Screw Jam Nut

5. If valves need adjusting, use the appropriate valve

clearance adjustment procedure on the next page and

adjust to specifications below. Loosen the jam nut (A)

on rocker arm adjusting screw. Turn adjusting screw

until feeler gauge slips with a slight drag. Hold the

adjusting screw from turning with screwdriver and

tighten jam nut to specifications. Recheck clearance

again after tightening jam nut. Readjust clearance as

necessary.

Specification

Intake Valve Clearance For

Adjusting (Rocker Arm-to-Valve

Tip) (Engine Cold)—Clearance 0.36 mm (0.014 in.)..................................

Exhaust Valve Clearance For

Adjusting (Rocker Arm-to-Valve

Tip) (Engine Cold)—Clearance 0.46 mm (0.018 in.)..................................

Rocker Arm Adjusting Screw Jam

Nut—Torque 27 N•m (20 lb-ft)....................................................................

6. Replace rocker arm cover and crankcase ventilator

tube.

Continued on next page

40-11

110306

PN=104