3.35

ENGINE

3

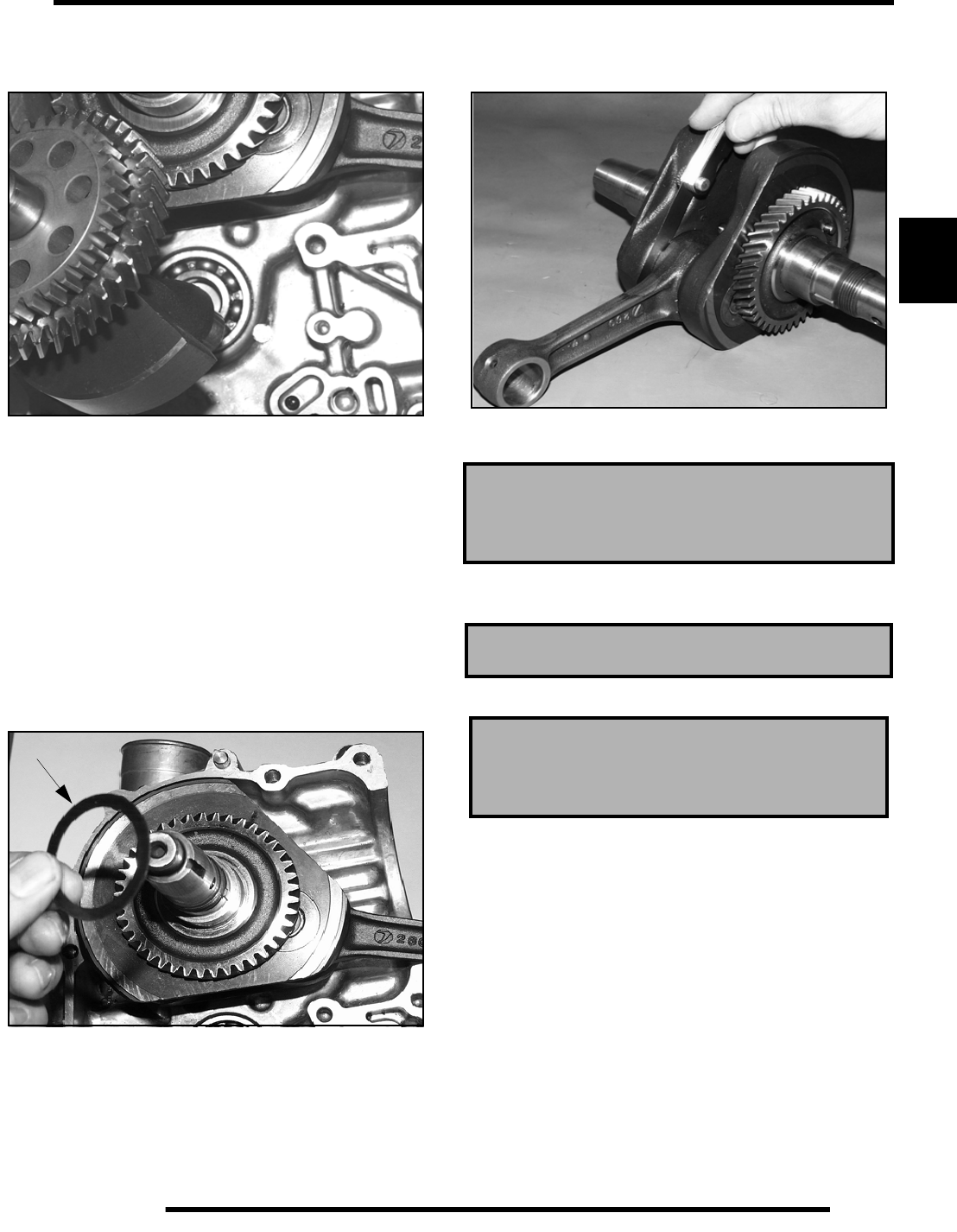

3. Turn the shaft until balancer counter weights clear the

crankshaft and remove the balancer shaft from the

crankcase.

4. Inspect the balancer drive gear and pump shaft drive gear.

5. Replace the shaft if gear teeth are abnormally worn or

damaged.

6. Inspect the balancer shaft bearings.

NOTE: Due to extremely close tolerances and minimal

wear, the balancer shaft ball bearings must be inspected

visually and by feel. Look for signs of discoloration,

scoring or galling. Turn the inner race of each bearing.

The bearings should turn smoothly and quietly. The outer

race of each bearing should fit tightly in the crankcase.

The inner race should be firm with minimal side to side

movement and no detectable up and down movement.

Crankshaft Removal/Inspection

7. Remove the shim washer (A) from the crankshaft.

8. Support the PTO side crankcase and crankshaft; press the

crankshaft out. Be careful not to damage the crankcase

mating surface or connecting rod.

9. Use a feeler gauge to measure the connecting rod big end

side clearance.

10. Place the crankshaft in a truing stand or V-blocks and

measure the runout on both ends with a dial indicator.

11. Measure the connecting rod big end radial clearance.

12. Inspect the crankshaft main bearing journals for scoring

and abnormal wear.

A

Connecting Rod Big End Side Clearance:

Std: .0039-.0256” (.1-.65 mm)

Limit: .0315” (.80 mm)

Max Runout: .0024” (.06 mm)

Big End Radial Clearance:

Std: .0004-.0015” (.011-.038 mm)

Limit: .0020” (.05 mm)