7.17

FINAL DRIVE

7

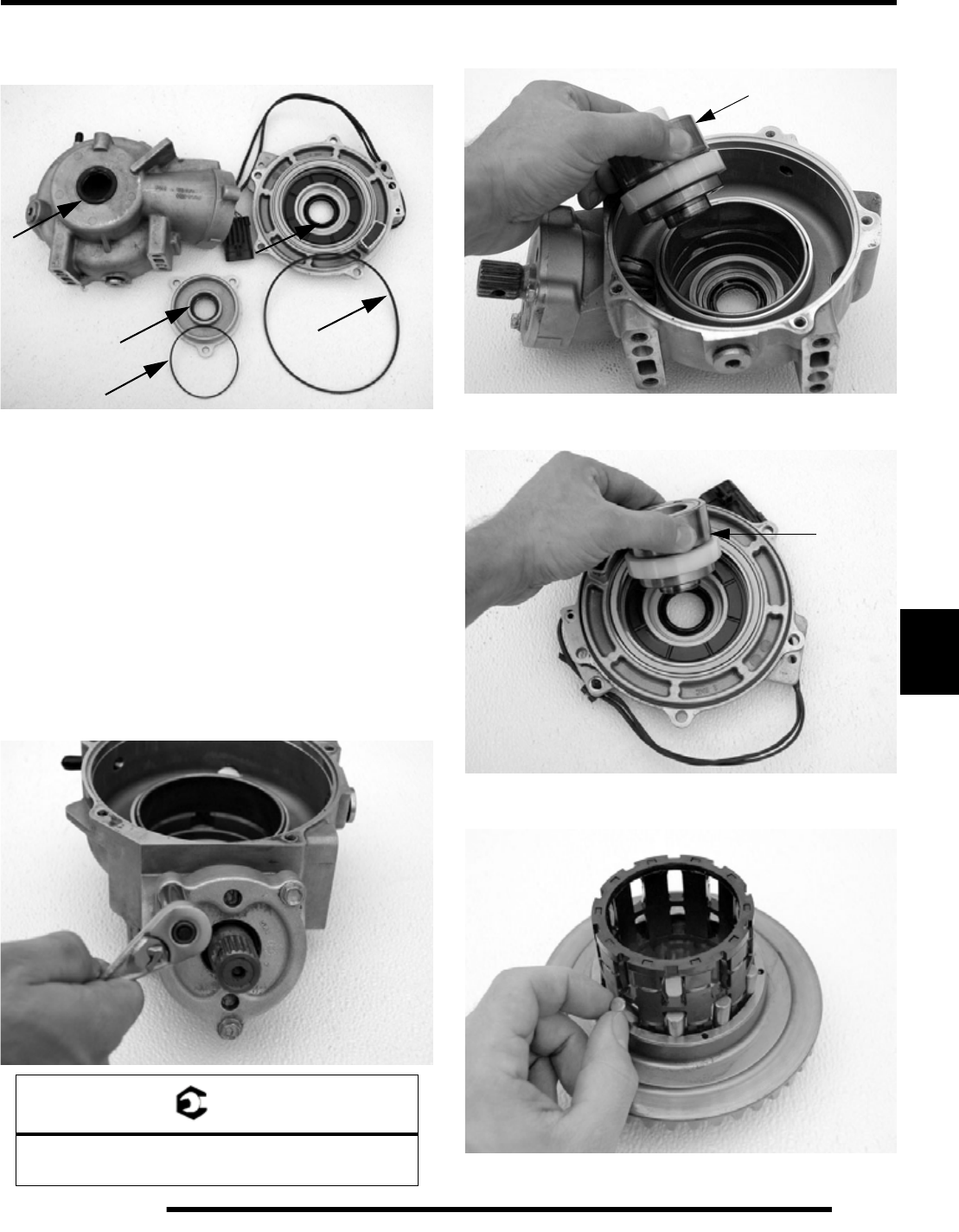

Reassembly / Inspection

1. Replace all O-rings, seals, and worn components.

2. Press the pinion shaft seal into the pinion cover, until the

seal is flush with the sealing surface.

3. Inspect bearings on output and pinion shafts. To replace,

press new bearing on to shaft.

NOTE: Due to extremely close tolerances and

minimal wear, the bearings must be inspected

visually, and by feel. While rotating bearings by

hand, inspect for rough spots, discoloration, or

corrosion. The bearings should turn smoothly and

quietly, with no detectable up and down movement

and minimal movement side to side.

4. Install input shaft, bearing, snap ring, and input cover with

new o-ring. Torque bolts to specification.

5. Install the LH output hub (A) into the gearcase housing.

The output hub should spin freely.

6. Install the RH output hub (B) into the output cover. The

output hub should spin freely.

7. Install the rollers and roll cage into the ring gear. Insert the

rollers as the roll cage is installed.

= T

Input Cover Bolt Torque

14 ft. lbs. (19 Nm)

A

A

B

C

B